00.00134.0152 A3 1:7

Transcript of 00.00134.0152 A3 1:7

F

1

E

D

32 4

C

B

A

1 32 4

F

E

D

5 6 7

C

B

8

A

Ohne

uns

ere

vorh

erige

Zust

immu

ng d

arf di

ese

Zeichn

ung

wede

r ve

rvielfä

ltigt

noc

h Dr

itten

zug

ängl

ich

gema

cht

werd

en, u

nd s

ie d

arf du

rch

den

Empf

änge

r od

er D

ritte

auc

hnich

t in a

nder

er W

eise

miß

bräu

chlic

h be

nutz

t we

rden

.

Werkstoff

Gewicht in kg

Format DIN

Revision

Zust Änderung

Verwendungszweck

Name

NameDatum CAD-Zeichnung

Gepr.Norm

BearbDatum

Ers.fürErs.durch

Zeichnungs-Nr.

Benennung

Halbzeug

Artikel-Nr.

Maßstab

Blatt

von

Bl.

*

AZul.Abweichungf.Maße ohne

ToleranzangabeISO 2768 - mH

Oberfläche nachDIN ISO 1302

43.0000

00.00134.0152-1

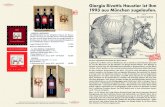

ANSCHLUSSARMATUR(SAUGSEITIG)

00.00134.0152

1

1

1:7.53

Schueppen07.09.200607.09.2006

BartonSzustkowski

008002 Puffer Filter nachgetrg 29.06.2004 Fra003 Puffer umgezeichnet004 Pos.40 & 80 entfällt 23.02.2005 Gut005 Stücklistenänderung 02.03.2005 Maa006 Positionsänderung 09.05.2005 Gut007 Solid-Edge Zchng. erst. 26.01.2006 Schü008 Solid-Edge Fehler 05.09.2006 Schü

SLeifeld

D-59302 OELDE

26.01.2006

07.07.2004 Fra

ß Mit Teile-Nr. signiert

Härte geprüftß

Mit Betriebsdruck signiert

alle Ecken und Kanten gratfrei

Mit Auftrags-Nr. signiertß

ß

*

268

1105

298

445

550

389,5

30

596

685

331

713,5

995

VorschweißflanschDN100; PN16; DIN-ISO 2633O 180(

)

(O18)

22,5°

SauganschlußLosflansch DN65; DIN 2642

101

201

301

504

608

704

1104

901

1003

1204

N° plan 00.00134.0152-100.00134.0152N° nomenclature

ARMATURE DE RACCORD, CôTE ASPIDescription Date :Page :

24.10.2008HDP 400, HDP 4801

NOMENCLATURE (42)

Hammelmann Maschinenfabrik GmbHPOB 3309, D-59282 Oelde, Germanymail to: [email protected]://www.hammelmann.de

PlanRep. NomRep. Référence Désignation Quantité No/Unité Unité

:::

1 1,001010 FILTRE pce00.00995.0058

1 1,002020 ARMATURE DE RACCORD, CôTE ASPI pce00.00134.0160

1 1,003030 BRIDE pce04.04475.0134

4 1,005050 VIS À TÊTE HEXAGONALE pce02.00671.0105

8 1,006060 PLAQUE pce02.00440.0001

4 1,007070 RONDELLE-RESSORT pce02.00380.0005

1 1,009090 MANOMETRE pce04.02860.0073

3 1,00100100 BOULON DE FERMETURE pce02.00805.0305

4 1,00110110 ECROU HEXAGONAL pce02.00309.0005

4 1,00120120 BUTOIRS pce04.03200.0007

p_dbgs01.p

>>>fin<<<

F

1

E

D

32 4

C

B

A

1 32 4

F

E

D

5 6 7

C

B

8

A

Ohne

uns

ere

vorh

erige

Zust

immu

ng d

arf di

ese

Zeichn

ung

wede

r ve

rvielfä

ltigt

noc

h Dr

itten

zug

ängl

ich

gema

cht

werd

en, u

nd s

ie d

arf du

rch

den

Empf

änge

r od

er D

ritte

auc

hnich

t in a

nder

er W

eise

miß

bräu

chlic

h be

nutz

t we

rden

.

Werkstoff

Gewicht in kg

Format DIN

Revision

Zust Änderung

Verwendungszweck

Name

NameDatum CAD-Zeichnung

Gepr.Norm

BearbDatum

Ers.fürErs.durch

Zeichnungs-Nr.

Benennung

Halbzeug

Artikel-Nr.

Maßstab

Blatt

von

Bl.

*

AZul.Abweichungf.Maße ohne

ToleranzangabeISO 2768 - mH

Oberfläche nachDIN ISO 1302

29.0000

00.00995.0058-1

FILTER

00.00995.0058

1

1

1:53

HEINR.07.09.200607.09.2006

BartonSzustkowski

005001 Diffdr. + Entl.-V. 17.11.1999 Sys002 Konvertierungsfehler003 Typenschild geändert 29.06.2004 Gut004 Pos.40 geändert 25.04.2005 Gut005 Solid-Edge Zchng. erst. 05.09.2006 Schü

SLeifeld

300l/min

D-59302 OELDE

16.12.1994

22.12.1999 HeinA A

A-AHammelmann Maschinenfabrik GmbH

Telefon 02522/76-0 Telefax 02522/76444

Zum Sundern 13-21 59302 Oelde Germany

Durchflussmenge l/min

Betriebstemperatur °C

Betriebsdruck max. bar

Baujahr / Serien-Nr.

Differenzdruck max. bar

Inhalt Liter

01.04565.0017

Artikel-Nr. 00.00995.0058

10

1,25 (+/-10%)

max.70

300

25

ß Mit Teile-Nr. signiert

Härte geprüftß

Mit Betriebsdruck signiert

alle Ecken und Kanten gratfrei

Mit Auftrags-Nr. signiertß

ß

*

1:10101

201

301

403

503

603

701

801

901

1001

1101

1201

1602

1903

2001

2104

114,3

O

520

655

268

176

169

963

14(O )

30

O11

Flansch DN65; PN10Anschlußmaße DIN 2642 Typenschild ausgefüllt!

Filterbeutelgehört nichtzur Baugruppe!

N° plan 00.00995.0058-100.00995.0058N° nomenclature

FILTREDescription Date :Page :

24.10.2008FILTRE 300LTR/MIN1

NOMENCLATURE (42)

Hammelmann Maschinenfabrik GmbHPOB 3309, D-59282 Oelde, Germanymail to: [email protected]://www.hammelmann.de

PlanRep. NomRep. Référence Désignation Quantité No/Unité Unité

:::

1 1,001010 RESERVOIR pce00.00222.0082

1 1,002020 COUVERCLE pce01.00665.0419

1 1,003030 JOINT TORIQUE pce04.00730.0504

3 1,004040 GOUPILLE CYLINDRIQUE pce01.05194.0117

3 1,005050 BOULON A OEILLET pce02.00503.0110

3 1,006060 ECROU A SIX PANS pce02.00301.0002

1 1,007070 RESSORT pce04.00946.0124

1 1,008080 SUPPORT DE FILTRE pce00.02166.0003

1 1,009090 BAGUE DE SUPPORT pce01.03478.0257

1 1,00100100 PLAQUE DE SUPPORT pce00.00273.0012

1 1,00110110 ROBINET A BOISSEAU SPHERIQUE pce04.01561.0107

1 1,00120120 SOUPAPE DE VIDANGE pce04.05866.0011

2 1,00160160 BOULONNAGE pce04.05993.0802

3 1,00190190 RONDELLE pce02.00421.0006

1 1,00200200 PLAQUE SIGNALÉTIQUE pce01.04565.0017

4 1,00210210 RIVET pce04.02970.0016

p_dbgs01.p

>>>fin<<<

N° plan 00.00134.0160-100.00134.0160N° nomenclature

ARMATURE DE RACCORD, CôTE ASPIDescription Date :Page :

24.10.2008HDP4001

NOMENCLATURE (42)

Hammelmann Maschinenfabrik GmbHPOB 3309, D-59282 Oelde, Germanymail to: [email protected]://www.hammelmann.de

PlanRep. NomRep. Référence Désignation Quantité No/Unité Unité

:::

1 1,001010 JOINT PLAT pce04.00709.0019

1 1,002020 BRIDE pce02.01272.0310

2 1,003030 COURBURE DE TUBE pce04.00426.0079

1 1,004040 ARMATURE DE RACCORD, CÔTE ASPI pce00.00134.0079

1 0,065050 TUBE m07.54301.0741

p_dbgs01.p

>>>fin<<<

N° plan 08.00210.0004-108.00210.0004N° nomenclature

TUYAU DE TROP-PLEINDescription Date :Page :

24.10.2008HDP 350,5501

NOMENCLATURE (42)

Hammelmann Maschinenfabrik GmbHPOB 3309, D-59282 Oelde, Germanymail to: [email protected]://www.hammelmann.de

PlanRep. NomRep. Référence Désignation Quantité No/Unité Unité

:::

2 1,001010 VIS À TÊTE HEXAGONALE pce02.00671.0104

2 1,002020 RONDELLE-RESSORT pce02.00380.0005

2 1,003030 ECROU HEXAGONAL pce02.00309.0005

1 1,004040 PASSE-TUYAU DN 40 pce04.05682.0051

2 1,005050 BRIDE pce04.04482.0129

1 1,006060 TUYAU pce01.04590.0007

1 1,007070 TUYAU pce01.04590.0005

1 1,008080 PIECE DE REDUCTION pce00.05320.0002

1 1,009090 BOULONNAGE pce04.05993.0498

1 1,00100100 BOULONNAGE pce04.05993.0404

1 1,00110110 ACCOUPLEMENT pce02.01495.0008

p_dbgs01.p

>>>fin<<<

N° plan 08.99109.0050-108.99109.0050N° nomenclature

CONDUITEDescription Date :Page :

24.10.20080-6BAR1

NOMENCLATURE (42)

Hammelmann Maschinenfabrik GmbHPOB 3309, D-59282 Oelde, Germanymail to: [email protected]://www.hammelmann.de

PlanRep. NomRep. Référence Désignation Quantité No/Unité Unité

:::

1 1,002020 ELECTROVANNE pce04.05875.0107

4 1,004040 BOULONNAGE pce04.05993.0840

2 1,005050 BOULONNAGE pce04.05993.0838

1 1,006060 REGULATEUR DE PRESSION pce00.03400.0001

1 1,007070 MANOMETRE pce04.02860.0065

1 1,008080 TUYAU m04.04590.0121

1 1,009090 SILENCIEUX pce04.00657.0010

2 1,00100100 BOULONNAGE pce04.05993.0837

p_dbgs01.p

>>>fin<<<

2

F

1

E

D

3 4

2

C

B

A

1 3 4

5

F

E

D

5 6 7

C

B

A

8Oh

ne u

nser

e vo

rher

ige

Zust

immu

ng d

arf dies

e Ze

ichn

ung

wede

r ve

rvielfä

ltigt

noc

h Dr

itten

zug

ängl

ich

gema

cht

werd

en, u

nd s

ie d

arf du

rch

den

Empf

änge

r od

er D

ritte

auc

hnich

t in a

nder

er W

eise

miß

bräu

chlic

h be

nutz

t we

rden

.

Werkstoff

Gewicht in kg

Format DIN

Revision

Zust Änderung

Verwendungszweck

Name

NameDatum CAD-Zeichnung

Gepr.Norm

BearbDatum

Ers.fürErs.durch

Zeichnungs-Nr.

Benennung

Halbzeug

Artikel-Nr.

Maßstab

Blatt

von

Bl.

*

AZul.Abweichungf.Maße ohne

ToleranzangabeISO 2768 - mH

Oberfläche nachDIN ISO 1302

9.3000

00.02125.0457-1

KONSOLE

00.02125.0457

1

1

1:52

ofranke18.07.200718.07.2007

BartonSzustkowski

001001 Darstellung geänd. 16.07.2007 Fra

SLeifeld

D-59302 OELDE

02.07.2007

1056

ca.

110

140

110

140

(M10)

220

378

35

40

20

O 11

498

50O 9

Gewinde desSchwingmetallpuffersauf 8mmkürzen!

177

ca.

ß Mit Teile-Nr. signiert

Härte geprüftß

Mit Betriebsdruck signiert

alle Ecken und Kanten gratfrei

Mit Auftrags-Nr. signiertß

ß

X*

101

202

306

402

501

601

704

804

904

F. ES-2 auf Rahmen

197161

N° plan 00.02125.0457-100.02125.0457N° nomenclature

CONSOLEDescription Date :Page :

24.10.2008ES-21

NOMENCLATURE (42)

Hammelmann Maschinenfabrik GmbHPOB 3309, D-59282 Oelde, Germanymail to: [email protected]://www.hammelmann.de

PlanRep. NomRep. Référence Désignation Quantité No/Unité Unité

:::

1 1,001010 CONSOLE pce00.02125.0456

2 1,002020 BUTOIRS pce04.03200.0003

6 1,003030 RONDELLE-RESSORT pce02.00380.0006

2 1,004040 VIS À TÊTE HEXAGONALE pce02.00671.0113

1 1,005050 PLATE EN ACIER pce01.05013.0021

1 1,006060 BRIDE pce01.04475.0005

4 1,007070 RONDELLE pce02.00421.0004

4 1,008080 VIS A TETE CYLINDRIQUE pce02.00830.0014

4 1,009090 VIS À TÊTE HEXAGONALE pce02.00671.0115

p_dbgs01.p

>>>fin<<<

H

1 2

G

F

E

3 4 5 6

D

C

B

A

1 2 3 4 5 6

7 8 9

H

G

F

E

7 8 9 10

D

C

B

A

11 12Oh

ne u

nser

e vo

rher

ige

Zust

immu

ng d

arf dies

e Ze

ichn

ung

wede

r ve

rvielfä

ltigt

noc

h Dr

itten

zug

ängl

ich

gema

cht

werd

en, u

nd s

ie d

arf du

rch

den

Empf

änge

r od

er D

ritte

auc

hnich

t in a

nder

er W

eise

miß

bräu

chlic

h be

nutz

t we

rden

.

Werkstoff

Gewicht in kg

Format DIN

Revision

Zust Änderung

Verwendungszweck

Name

NameDatum CAD-Zeichnung

Gepr.Norm

BearbDatum

Ers.fürErs.durch

Zeichnungs-Nr.

Benennung

Halbzeug

Artikel-Nr.

Maßstab

Blatt

von

Bl.

*

AZul.Abweichungf.Maße ohne

ToleranzangabeISO 2768 - mH

Oberfläche nachDIN ISO 1302

50.0000

00.06020.0112-1

VORRICHTUNG

00.06020.0112

1

1

1:51

Maas02.03.200603.03.2006

BartonSzustkowski

002001 Stücklistenänderung 14.12.2005 Maa002 Pos.50,230 geändert

SLeifeld

D-59302 OELDE

07.12.2005

02.03.2006 Schü

145

200

145

200

M20

1860

331

767

532,5

409,5 34

34

ß Mit Teile-Nr. signiert

Härte geprüftß

Mit Betriebsdruck signiert

alle Ecken und Kanten gratfrei

Mit Auftrags-Nr. signiertß

ß

*

- Hebevorrichtung für Pumpenkopf HDP 250/360/480

- Tragkraft max. 350kg

1:10

A

A1:2

B

B1:2

C

C1:1

DD

D-D101

201

301

401

501

601

703

803

902

1001

1101

1203

1301

1402

1501

1601

1701

1802

1901

2002

2102

2202

2301

2401

2504

2704

002002

5min.

min.O25

N° plan 00.06020.0112-100.06020.0112N° nomenclature

DISPOSITIFDescription Date :Page :

24.10.2008HDP250/360/4801

NOMENCLATURE (42)

Hammelmann Maschinenfabrik GmbHPOB 3309, D-59282 Oelde, Germanymail to: [email protected]://www.hammelmann.de

PlanRep. NomRep. Référence Désignation Quantité No/Unité Unité

:::

1 1,001010 FIXATION pce00.01630.0982

1 1,002020 FIXATION pce00.01630.0645

1 1,003030 DOUILLE pce01.00525.0502

1 1,004040 CAPUCHON pce01.01880.0042

1 1,005050 VIS SANS TETE pce02.00884.0110

1 1,006060 TREUIL DE MANOEUVRE pce04.06208.0007

3 1,007070 RONDELLE pce02.00421.0006

3 1,008080 VIS A TETE CYLINDRIQUE pce02.00825.0018

2 1,009090 POULIE pce01.03595.0135

1 1,00100100 ESSIEU pce01.00001.0242

1 1,00110110 BAGUE DE BUTÉE pce02.00388.0013

3 1,00120120 RONDELLE pce02.00421.0009

1 1,00130130 ECROU A SIX PANS pce02.00314.0005

2 1,00140140 PIECE DE TUBE pce01.05323.0168

1 1,00150150 BOULON À TÊTE HEXAGONALE pce02.00654.0321

1 5,00160160 CABLE METALLIQUE m02.01751.0001

1 1,00170170 PLATE EN ACIER pce01.05013.0128

2 1,00180180 VIS À TÊTE HEXAGONALE pce02.00671.0114

1 1,00190190 PIECE DE FIXATION pce01.05308.0043

2 1,00200200 VIS À TÊTE CONIQUE pce02.00734.0114

2 1,00210210 RONDELLE-RESSORT pce02.00380.0005

2 1,00220220 ECROU HEXAGONAL pce02.00309.0005

1 1,00230230 BOULON A SIX PANS pce02.00671.0124

1 1,00240240 ECROU HEXAGONAL pce02.00309.0007

4 1,00250250 BOULON A SIX PANS pce02.00671.0137

4 1,00270270 RONDELLE pce02.00421.0010

p_dbgs01.p

>>>fin<<<

Transmetteurspour la basse pressionHDA 4100 / HDA 4300

DescriptionLes transmetteurs de la sérieHDA 4100 et HDA 4300 disposentd'une cellule de mesure céramiquesur couche épaisse, développéespécialement pour des applicationsbasse pression. Les signaux de sortie4 .. 20 mA ou 0 .. 10 V permettent leraccordement à des appareils demesure et de pilotage de la sociétéHYDAC ELECTRONIC GmbH ainsique l'ajout d'unité de pilotage et derégulation que l'on trouve sur lemarché.Les principaux domaines d'applicationse situent dans les secteurs bassepression de l'hydraulique et dupneumatique, notamment dans lesapplications de la technique du froidet de la climatisation, l'industriealimentaire et pharmaceutique.

CaractéristiquesparticulièresPrécision ≤±0,5%PE typiqueTrès grande stabilité

en températureExcellente compatibilité

électromagnétiqueForme compacteTrès bon rapport qualité/prix

Données techniquesCaractéristiques d'entréePlage de mesure absolue 1; 2,5 barPlage de mesure relative 1; 2,5; 4; 6; 10; 16; 25; 40 bar

-1 .. 5 bar; -1 .. 9 barSurcharge 300 % FSPression d'éclatement 400 % FSRaccordement mécanique G 1/4 A DIN 3852; G 1/2 B DIN-EN 837Couple de serrage 20 Nm (G1/4, 1/4-18NPT), 45 Nm (G1/2)Matériaux en contact avec le fluide céramique, acier inox 1.4542, joint : cuivre

(G1/2)/FPM/EPDM (selon code de commande)Caractéristiques de sortieDérive de précision / droite passant par ≤ ±0,5 %PE typ.les extrémités de réglages d'après ≤ ±1%PE max.DIN 16086 (classe de précision)Dérive de précision par rapport ≤ ±0,25 %PE typ.à la meilleure droite (BFSL) ≤ ±0,5 %PE max.Coefficient de température au point zéro ≤ ±0,02 %PE/°C typ.

≤ ±0,03 %PE/°C max.Coefficient de température sur la sensibilité ≤ ±0,02 %PE/°C typ.

≤ ±0,03 %PE/°C max.Linéarité par rapport au maximum ≤ ±0,5 %PE max.de la droite passant par les extrémitésde réglages d'après DIN 16086Hystérésis ≤ ±0,25 %PE max.Reproductibilité ≤ ±0,1 %PETemps de réponse env. 2 msDérive dans le temps ≤ ±0,3 %PE typ. / annéeCaractéristiques de l'environnementPlage de température nominale 0 .. +80 °CPlage de température d'utilisation -25 .. +85 °CPlage de température de stockage -40 .. +100 °CPlage de température du fluide -40 .. +100 °C

Sigle EN 61000-6-1, EN 61000-6-2EN 61000-6-3, EN 61000-6-4

Résistance aux vibrations d'après ≤ 20 g (196,2 m/s²)IEC 68-2-6 à 10 .. 500 HzIndice de protection d'après DIN 40050 IP 65 (connecteur Hirschmann DIN 43650

et Binder 714 M 18)IP 67 (connecteur M12X1 lors del'utilisation d'un connecteur coudé)

Autres caractéristiquesTension d'alimentation bipolaire, 4 .. 20 mA 10 .. 30 V DCTension d'alimentation tripolaire, 0 .. 10 V 12 .. 30 V DCOscillation résiduelle de la tension d'alimentation ≤ 5 %Courant absorbé, tripolaire env. 25 mAProtection contre l'inversion de la polarité disponiblede la tension d'alimentation, contre lessurtensions; Protection contre lescourts-circuitsDurée de vie >10 millions de cycles (0 .. 100 %PE)Masse env. 150 gRemarque : P.E. (Pleine Echelle) = se base sur toute la plage de mesure.

HAMMELMANN Référénce no.: 04.00829.0046Type HDA 4346-A-0016-000-F1

2

Encombrements

HDA 4144, HDA 4344 avec ZBE 03

HDA 4145, HDA 4345 avec ZBE 01

Raccordement électriqueBipolaire 4 .. 20 mA

HDA41xx-AHDA43xx-A

Tripolaire 0 .. 10 V

+UB

0V

+UB

0V

RemarqueLa résistance de charge RL résulte de la somme de la résistance demesure incorporée dans la cellule et de la résistivité du câble deliaison.

Occupation des bornes (HDA 4100 / HDA 4300)

Borne 1 Borne 2 Borne 3 Borne 4HDA 41X4-AHDA 43X4-A

libre +UB 0V libre

HDA 41X4-BHDA 43X4-B

+UB Signal 0V libre

HDA 41X5-AHDA 43X5-A

+UB 0V libre

HDA 41X5-BHDA 43X5-B

+UB 0V Signal

HDA 41X6-AHDA 43X6-A

+UB libre 0V libre

HDA 41X6-BHDA 43X6-B

+UB libre 0V Signal

Accessoires électriques

ZBE 02 Connecteur droit4 pôles BINDER, série 714 M18

ZBE 03 Connecteur coudé4 pôles BINDER, série 714 M18

dimension X avec connecteur coudé ZBE 03 : 106 mmdimension X avec connecteur droit ZBE 02 ≈ 125 mmRLmin. = 2KΩ

RLmax.= UB - 10 V

[Ω] 0,02 A

SignalHDA41xx-BHDA43xx-B

HDA 41X4 HDA 41X5 HDA 41X6HDA 43X4 HDA 43X5 HDA 43X6

ZBE 01 Connecteur coudé3 pôles + terre DIN 43650/ISO 4400

ZBE 06 (4 pôles)Connecteur coudé M12x1

Jointd'étanchéité profilé

∅27

.5

≈35.5

M3

≈35 ∅

25.5

≈62

≈30

43

∅25

.5

HDA 4146, HDA 4346 avec ZBE 06

Autres variantes deraccordement mécanique

1/4-18 NPT

G1/2B DIN-EN 837

6kt-

SW

276k

t-S

W27

HAMMELMANN Référénce no.: 04.00829.0046Type HDA 4346-A-0016-000-F1

3

Code de commande HDA 4 X X X - X - XXXX - 000 - X 1

Exécution (technologie)1 = céramique absolue3 = céramique relative

Raccordement mécanique1 = G1/2 B DIN-EN 837 (fileté)4 = G1/4 A DIN 3852 (fileté)8 = 1/4-18 NPT (fileté)

Raccordement électrique4 = Connecteur 4 pôles BINDER Série 714 M18 (livré sans connecteur)5 = Connecteur 3 pôles + Terre DIN 43650 (livré avec connecteur)6 = Connecteur M12x1, 4 pôles (livré sans connecteur)

SignalA = 2 fils, 4 .. 20 mAB = 3 fils, 0 .. 10 V

Plage de pression en barPour l'exécution "1" (céramique absolue)01,0 / 02,5 barPour l'exécution "3" (céramique relative)01,0 / 02,5 / 04,0 / 06,0 / 0010 / 0016 / 0025 / 0040 bar0005 (-1 .. +5bar) / 0009 (-1 .. +9bar)

Indice de modification000 = Standard

Matériau des joints (en contact avec le fluide)F = joint FPM (p. ex. pour huiles hydrauliques)E = joint EPDM (p.ex. pour fluides de refroidissement)

Matériau de raccordement (en contact avec le fluide)1 = acier inoxydable

Attention :Pour des appareils avec d'autres indices de modification, veuillez respecterla plaque signalétique ou le descriptif technique de modification livré.

RemarqueLes données de ce prospectus se réfèrentaux conditions de fonctionnement etd'utilisation décrites.Pour des conditions d'utilisation et defonctionnement différentes, veuillez vousadresser au service technique compétent.Sous réserve de modifications techniques.

HAMMELMANN Référénce no.: 04.00829.0046Type HDA 4346-A-0016-000-F1

Tech

nisc

he Ä

nder

unge

n vo

rbeh

alte

n.A

rt.-

Nr.:

923

-156

1, In

dex

: A

Barksdale

Elektronische Druckaufnehmer

Technische Daten

Sensorelement: Aufgeklebter metallischer Dehnungsmessstreifen (vier aktive Zweige)

Werkstoffe:medienberührte Teile:Elektronikgehäuse:

Edelstahl AISI 304Edelstahl 15-5 PH

Schutzart : IP65

Prozessanschluss: G 1/2“ A

Abmessungen: Ø43 x 171 mm(ohne Kupplungsdose)

Gewicht: 340 g

Druckbereich: 0 ... 1600

Max. zulässige Überlast: (ohne Beeinflussung der Kenndaten)2x Endwertmax. 3200 bar

Berstdruck: 3x Endwertmax. 4800 bar

Kennlinienabweichung: <0,3 % v. M. E.

Signaleinstellung:Nenndruck:Umgebungsdruck:

±0,5 % v. M. E.±0,5 % v. M. E.

Elektrischer Anschluss: Gerätestecker 3-polig + PE, DIN EN 175 301-803-A (vorm. DIN 43650)

Temperaturdrift:im kompens. Bereich:

(Nullpunkt - Spanne - Kalibrierwert)<±0,02 % v. M. E. / °C<±0,01 % v. M. E. / °F

Kompens. Temperatur-bereich: 0 ... 70 °C / 32 ... 158 °F

Zulässiger Temperatur-bereich:

–30 ... +85 °C / –22 ... 185 °F

Versorgungsspannung: 10 ... 30 V DC

Signal:bei Nenndruck:

bei Umgebungsdruck:

(±0,5% v. M. E.)20 mA(±0,5% v. M. E.)4 mA

Isolationswiderstand: (bei 50 V DC) >1000 MΩ

Max. zulässige Bürde: siehe Lastdiagramm

Max. Ansprechzeit: (0 ... 90% v. M. E.)4 ms

Kurzschluss- und Verpolungsschutz der Spannungsversorgung

ja

Elektronischer Druckaufnehmer für Hochdruckeinsatz mit innenliegender Edelstahlmembran, Kennlinienabweichung 0,3% v. M. E.

MerkmaleRobuste EdelstahlausführungKompakte BauweiseHohe ÜberdrucksicherheitGute Langzeitstabilität

Bestell- / TeilenummernBarksdale Bestell-Nr.: 0436-016Hammelmann Teile-Nr.: 04.00829.0048

Elektronische Druckaufnehmer Typ UPA 2 - TPHA

1

HAMMELMANN Artikel-Nr.: 04.00829.0048

Druckaufnehmer Typ UPA2-TPHA 1600

Tech

nisc

he Ä

nder

unge

n vo

rbeh

alte

n.A

rt.-

Nr.:

923

-156

1, In

dex

: A

Barksdale

Druck66

/ 2,

6

ø32 / 1,26

Ch. 22

G 1/2“

ø43 / 1,69

61 /

2,4

24 /

0,94

Nutzbereich

Last

wid

erst

and

RI

Versorgungsspannung

Elektronische Druckaufnehmer

Abmessungen (in mm / inch)

Elektronische Druckaufnehmer Typ UPA 2 - TPHA

Anschlusstabelle

Lastdiagramm (Stromausgang)

AnschlussStromausgang 4...20 mA (2-Leiter)

Stecker

+ Signal 1

- Signal 2

2

HAMMELMANN Artikel-Nr.: 04.00829.0048

Druckaufnehmer Typ UPA2-TPHA 1600

Insert filtersEinbaufilterParties intérieur es intégrées

Type I/Model IN-AGB

Flow rate:up to 2000 l/min

Nennvolumenstrom:bis 2000 l/min

Débit:jusqu’à 2000 l/min

MBC

009

rev

7-0

5-03

Mo

del

IN

-AG

B

G l o b a l F i l t r a t i o n T e c h n o l o g yMember of Parker Hannifin Corporation

HAMMELMANN Artikel-Nr. / Code no. / Référénce no.: 04.00995.0177Einbausatz / Insert / Partie intérieur IN-AGB1-125

HAMMELMANN Artikel-Nr. / Code no. / Référénce no.: 04.00995.0177Einbausatz / Insert / Partie intérieur IN-AGB1-125

SYMBOL EXPLANATION

SYMBOL DESCRIPTION UNIT

ALCdEFcFµ

FtGDLHMhMwcNAOrqPbPiP0POMPwQdSmStd

AluminiumPort dimension (BSP/G)ElementFluid compatibilityFilter finenessXW Media type - Glass fibreXX Media type - CelluloseS Media type - Steel meshFunctional testMedia type HPFE Low pr.HousingMaterial filter housingMax. water contentNot applicableOn requestBurst pressureIndicator settingBy-pass settingPlasticMax. working pressureFlow directionSeal materialStandard

Inch##Micron

####ppm

#barbarbar

bar###

SYMBOL ERKLÄRUNG

SYMBOL BESCHREIBUNG EINHEIT

ALCdEFcFµ

FtGDLHMhMwcNAOrqPbPiP0POMPwQdSmStd

AluminiumAnschluß (BSP/G)ElementFluid VerträglichkeitFilterfeinheitXW Filtermedia GlasfaserXX Filtermedia ZelluloseS Filtermedia EdelstahlgewebeFunktionstestFiltermedia HPFE NiederdruckFiltergehäuseWerkstoff FiltergehäuseMax. WassergehaltNicht zutreffendAuf AnfrageBerstdruckIndikatoranzeigeBy-pass ÖffnungsdruckPlastikMax. NenndruckDurchfluß RichtungDichtungsmaterialStandard

Inch##Micron

####ppm

#barbarbar

bar###

EXPLICATION DE SYMBOLE

SYMBOLE DESCRIPTION UNITÉ

ALCdEFcFµ

FtGDL

HMhMwcNAOrqPbPiP0POMPwQdSmStd

AluminiumRaccordements (BSP/G)ÉlémentCompatibilité des fluidesFinesses de filtrationXW Fibre de verreXX CelluloseS Toile métallique inox.Test normalisé utiliséMédia type HPFE haute efficacité basse pressionCorps de filtreMatière du corps de filtreTaux d’eau max.Non applicableSur demandePression d’éclatementTarage de l’indicateurTarage de by-passPlastiqueMax. pression de serviceSens du débitMatière de jointsStandard

Inch##Micron

##

##ppm

#barbarbar

bar###

HAMMELMANN Artikel-Nr. / Code no. / Référénce no.: 04.00995.0177Einbausatz / Insert / Partie intérieur IN-AGB1-125

2

COMPANY PROFILE UNTERNEHMENS PROFIL PROFIL DE L’ENTREPRISE

Parker Arlon is a leading designer and

manufacturer of filters for hydraulic and

lubricating oil systems used in mobile and

industrial applications throughout the

world. The company offers standard,

semi-standard and tailor-made solutions

that meet all requirements. The product

portfolio encompasses a wide variety of

indicators, 3-way ball valves and filter ele-

ments, including the innovative LEIF®

Low Environmental Impact Filter and

AQUASAFE® water absorption elements.

In addition, Parker Arlon provides oil ana-

lysis services.

In-depth know-how and experience,

combined with an awareness of market

demands and customer requirements are

the foundation of Parker Arlon’s customer-

oriented approach. The company is pur-

suing new standards, not only in filtration

efficiency and customer service, but also

in environmental consciousness. Parker

Arlon is ISO 9001 and ISO 14001 certi-

fied. Quality & environment are conveyed

through technical efficiency, consistency,

long lifecycles and cost efficiency.

Parker Arlon has engineering, R&D

and manufacturing facilities located in

Arnhem, the Netherlands, and exports

90% of its products around the world.

Parker Filtration BV is part of the

Parker Hannifin Corporation – the world’s

largest motion and control company,

manufacturing and supplying components

and systems for just about anything that

moves.

Parker Arlon ist ein führender

Entwickler und Hersteller von

Filtrationsprodukten für Hydraulik- und

Schmierölsysteme, welche weltweit auf

dem Mobil- und Industrie-Sektor ihre

Anwendung finden.

Mit seinen Standards, Halbstandards

und kundenorientierten Lösungen bedient

die Firma eine Vielzahl von Anforderungen.

Die Produktpalette umfasst eine breite

Vielfalt von Indikatoren, 3-Wege-Kugel-

hähnen und Filterelementen einschließlich

der innovativen, umweltfreundlichen LEIF®

Filter und AQUASAFE® wasserabsorbieren-

den Elementen. Zusätzlich bietet Parker

Arlon einen Ölanalyse-Service an.

Der langjährige know-how und

Erfahrung zusammen mit der

Wahrnehmung hoher Kunden- und

Marktansprüche ist die Grundlage für die

kundenorientierte Ausprägung von Parker

Arlon. Die Umsetzung neuester Standards

zeigt sich gleichermaßen in der Qualität

unserer Produkte, einem hohen Niveau an

Kundenservice, wie in der Verfolgung

umwelt- politischer Aspekte. Parker Arlon

ist ISO 9001 und 14001 zertifiziert.

Qualität und Umwelt-Verantwortung kom-

men durch technische Effizienz,

Konsistenz, lange Lebenszyklen und

Kosteneffizienz zum Ausdruck.

Parker Arlon vereint Engineering,

Forschung & Entwicklung sowie

Produktion am Standort in Arnheim,

Niederlande. 90% der Produkte werden in

die ganze Welt exportiert.

Parker Filtration BV ist Teil der Parker

Hannifin Corporation, einer der interna-

tional führenden Anbieter auf dem Gebiet

der Antriebstechnik.

Parker Arlon est un des tous premiers

concepteurs et fabricants mondiaux de

filtres hydrauliques et de lubrification pour

l’industrie et les applications mobiles.

La société propose des solutions stan-

dards, semi-standards et personnalisées

pour toutes les demandes.

La gamme de produits comprend une

grande variété d’indicateurs, des vannes 3

voies sphériques, d’éléments filtrants tels

les innovants LEIF® filtre écologique et

AQUASAFE®, élément absorbant l’eau.

De plus, Parker Arlon assure un service

d’analyse d’huile.

Un grand savoir-faire et une longue

expérience, ainsi qu’une connaissance des

besoins du marché et des clients sont les

bases de l’approche client de Parker Arlon.

La société explore de nouveaux domaines,

non seulement dans l’efficacité de filtra-

tion et le service client, mais aussi dans la

prise de conscience environnementale.

Parker Arlon est certifié ISO9001 et

ISO14001. Qualité et environnement se

traduisent par efficacité technique, qualité

constante, longues durées de vie et effica-

cité économique.

Parker Arlon a ses bureaux d’études,

Recherche et Développement et usine de

production à Arnhem en Hollande, et

exporte 90% de sa production dans le

monde entier.

Parker Filtration BV appartient au

groupe Parker Hannifin Corporation, la

plus grande société du monde spécialisée

dans la fabrication de composants pour le

contrôle des mouvements et des fluides.

G l o b a l F i l t r a t i o n T e c h n o l o g y

HAMMELMANN Artikel-Nr. / Code no. / Référénce no.: 04.00995.0177Einbausatz / Insert / Partie intérieur IN-AGB1-125

ASSEMBLY PARTS TEILE-LISTE PIECES DETACHEES

TECHNICAL INFORMATION TECHNISCHE BESCHREIBUNG INFORMATIONS TECHNIQUES

FILTRATION EFFICIENCY ABSCHEIDE RATE EFFICACITÉ DE FILTRATION

MEDIAFILTERMEDIAMÉDIA

MICRONMIKRONMICRON

FILTRATION RATIOFILTER FEINHEIT

NIVEAU DE FILTRATION

β−

X≥75 β−

3 β−

6 β−

10 β−

12 β−

20 β−

25 β−

55

GDL1GDL3GDL6GDL10GDL20XX10

136

102033

400≥75

85

N/AN/A

40001000≥75

172

N/A

>5000>5000

1000≥75

82.6

>5000>5000>5000

>20010

3.5

>5000>5000>5000>5000

≥756

>5000>5000>5000>5000>5000

23

>5000>5000>5000>5000>5000>5000

ITEM NUMBERTEIL NUMMERNUMÉRO DE PART

DESCRIPTION

1

2

3

4

5

6.1

6.2

7

8

9

Top-spring

Insert

Insert seal

By-pass seal

Filter element

Tank seal AGB-3

Tank seal AGB-4

Element seal

By-pass set

Funnel/diffuser

Feder

Einbausatz

O-ring Einbausatz

By-pass Dichtung

Filterelement

Behälter Dichtung AGB-3

Behälter Dichtung AGB-4

O-ring Element

By-pass Satz

Auslaufrohr

Ressort supérieur

Partie intérieure

Joint de partie intérieure

Joint de by-pass

Élément de filtrant

Joint de réservoir AGB-3

Joint de réservoir AGB-4

Joint de l’élément

Ensemble by-pass

Bac d’écoulement

BESCHREIBUNGDESCRIPTION

FILTER/FILTER/FILTRE

MEDIA/MEDIUM/MÉDIUM

GENERAL/ALGEMEIN/GÉNÉRALES

Q max IN-AGB-1 = 125 l/minQ max IN-AGB-2 = 300 l/minQ max IN-AGB-3 = 500 l/minQ max IN-AGB-4 = 2000 l/min

T: –400C/+1200C

INSERT/EINBAUSATZ/PARTIE INTÉRIEUR

AGB-1-30 m: 0,5 kgAGB-1-60 m: 0,6 kgAGB-1-90 m: 0,8 kgAGB-1-120 m: 0,9 kgAGB-1-125 m: 1,1 kgAGB-2-170 m: 2,1 kgAGB-2-230 m: 2,2 kgAGB-2-300 m: 2,4 kgAGB-3-270 m: 2,8 kgAGB-3-390 m: 3,0 kgAGB-3-500 m: 3,6 kg

AGB-4-600 m: 13,0 kgAGB-4-800 m: 14,0 kgAGB-4-1000 m: 16,8 kgAGB-4-1500 m: 21,4 kgAGB-4-2000 m: 28,3 kg

Sm: NBR, CR, FPM

Pb: 10 bar

Qd: In/Out; Innen/Aussen; Intérieur/Extérieur

Fµ XW: GDL 1 - 3 - 6 - 10 - 20µmFµ S: 40 - 120µmFµ XX: 10µm nom

MWc: 500 ppm

Ft: ISO 2941ISO 2942ISO 2943ISO 3724ISO 3968ISO 4572

Fc: Oil type; Öl Type; Type d’huileHH - HL - HLP - HVHETG - HEPG - HEESHFA (mineral base) - HFB - HFCHFA (synthetic base) - Orq Pleasecontact Parker Arlon

3

P0: 0,8 / 1,5 bar

BY-PASS/BY-PASS/BY-PASS

G l o b a l F i l t r a t i o n T e c h n o l o g y

HAMMELMANN Artikel-Nr. / Code no. / Référénce no.: 04.00995.0177Einbausatz / Insert / Partie intérieur IN-AGB1-125

ENCOMBREMENTEINBAU-ABMESSUNGENINSTALLATION DIMENSIONS

4

TYPETYPTYPE

yxdhHBA s p C D E F G

IN-AGB1-30IN-AGB1-60IN-AGB1-90IN-AGB1-120IN-AGB1-125IN-AGB2-170IN-AGB2-230IN-AGB2-300IN-AGB3-270IN-AGB3-390IN-AGB3-500IN-AGB4-600IN-AGB4-800IN-AGB4-1000IN-AGB4-1500IN-AGB4-2000

66666888

1212121212121212

44444555777

13.513.513.513.513.5

20202020202525253030304040404040

3535353535484848626262

100100100100100

122173217267381284360559325405595505615720

10001265

7979797979

116116116138138138216216216216216

8787878787

125125125150150150230230230230230

4545454545777777

100100100142142142142142

20202020204242425555556060606060

8888888888

126126126151151151231231231231231

8585858585

122122122149149149227227227227227

8080808080

117117117139139139217217217217217

4444455555566666

12121212121515151818182020202020

TYPETYPTYPE

RQVUMLK

IN-AGB3-270IN-AGB3-390IN-AGB3-500

IN-AGB4-600IN-AGB4-800IN-AGB4-1000IN-AGB4-1500IN-AGB4-2000

2.52.52.52.52.5

178178178

250.5250.5250.5250.5250.5

555555

6060606060

106106106

145145145145145

175175175

239239239239239

110110120

183183183183183

290370560

445555660940

1205

MOUNTING ARRANGEMENT

AGB 3 AGB 4

G l o b a l F i l t r a t i o n T e c h n o l o g y

HAMMELMANN Artikel-Nr. / Code no. / Référénce no.: 04.00995.0177Einbausatz / Insert / Partie intérieur IN-AGB1-125

∆p/Q COURBES DE DÉBIT∆p/Q KENNLINIEN∆p/Q GRAPHS

5

T- -elements

T3D-elements

T5-elements

T8A-elements

T11-elements

T14-elements

T2-elements

T3E-elements

T5A-elements

T8C-elements

T3-elements

T4-elements

T6A-elements

T10-elements T12-elements

T13-elements T-elements

FLUID/FLUID/FLUIDE ν = 32cSt

G l o b a l F i l t r a t i o n T e c h n o l o g y

HAMMELMANN Artikel-Nr. / Code no. / Référénce no.: 04.00995.0177Einbausatz / Insert / Partie intérieur IN-AGB1-125

∆p/Q COURBES DE DÉBIT∆p/Q KENNLINIEN∆p/Q GRAPHS

CALCUL ∆p ∆p KALKULATION∆p CALCULATION

FLUID/FLUID/FLUIDE A:νa = 32cSt / γ = 0.87

∆p E = 0.5 bar∆p H = 0.1 bar∆p Tot. A = 0.6 bar

FLUID/FLUID/FLUIDE B: νb = 46cSt / γ = 1.1

∆p E = (46/32)x0.5 = 0.72 bar∆p H = (1.1/0.87)x0.1 = 0.13 bar∆p Tot.B = 0.85 bar

6

T3D-elements

T5-elements

T8A-elements

T11-elements

T14-elements

T3E-elements

T5A-elements

T8C-elements

T3-elements

T4-elements

T6A-elements

T10-elements

T12-elements T13-elements

T2-elements

G l o b a l F i l t r a t i o n T e c h n o l o g y

HAMMELMANN Artikel-Nr. / Code no. / Référénce no.: 04.00995.0177Einbausatz / Insert / Partie intérieur IN-AGB1-125

7

ORDERING INFORMATION / BESTELLDATEN / COMMENT PASSER VOTRE COMMANDE

G l o b a l F i l t r a t i o n T e c h n o l o g y

1

Variety/

Ausfuhrung/

Variante code

30IN-AGB 1-30

60

90

120

125

170

230

300

270

390

500

600

800

1000

1500

2000

IN-AGB 1-60

IN-AGB 1-90

IN-AGB 1-120

IN-AGB 1-125

IN-AGB 2-170

IN-AGB 2-230

IN-AGB 2-300

IN-AGB 3-270

IN-AGB 3-390

IN-AGB 3-500

IN-AGB 4-600

IN-AGB 4-800

IN-AGB 4-1000

IN-AGB 4-1500

IN-AGB 4-2000

3

Diffuser/

Auslaufrohr/

Bac d’ecoulement code

T

-

5

code

08

15

B

2

Element/

Element/

Élément

Nominal

Cellulose/

Zellulose/

Cellulose

Stainless steel mesh/

Rostfrei Metallgewebe/

Toile métallique inoxydable

Filtration fineness absolute/ Filterfeinheit Absolut/ Finesse de filtration absolue

HPFE glass fibre/ HPFE Glasfaser/ HPFE fibre de verre β−X≥75

LEIF®

3µm 6µm 10µm10µm 20µm 40µm

code code codecode code code

TXWL-3 TXWL-6 TXWL-10TXX-10 TXWL-20 ST-40

TXWL2-3 TXWL2-6 TXWL2-10TXX2-10 TXWL2-20 ST2-40

TXWL3-3

TXWL3D-3

TXWL3E-3

TXWL4-3

TXWL5-3

TXWL5A-3

TXWL6A-3

TXWL8A-3

TXWL8C-3

TXWL10-3

TXWL11-3

TXWL12-3

TXWL13-R-3

TXW14-3

TXWL3-6

TXWL3D-6

TXWL3E-6

TXWL4-6

TXWL5-6

TXWL5A-6

TXWL6A-6

TXWL8A-6

TXWL8C-6

TXWL10-6

TXWL11-6

TXWL12-6

TXWL13-R-6

TXW14-6

TXWL3-10

TXWL3D-10

TXWL3E-10

TXWL4-10

TXWL5-10

TXWL5A-10

TXWL6A-10

TXWL8A-10

TXWL8C-10

TXWL10-10

TXWL11-10

TXWL12-10

TXWL13-R-10

TXW14-10

TXX3-10

TXX3D-10

TXX3E-R-10

TXX4-10

TXX5-10

TXX5A-10

TXX6A-10

TXX8A-10

TXX8C-10

TXX10-10

TXX11-10

TXX12-10

TXX13-R-10

TXX14-10

TXWL3-20 ST3-40

TXWL3D-20 ST3D-40

TXWL3E-20 ST3E-R-40

TXWL4-20

TXWL5-20

TXWL5A-20

TXWL6A-20

TXWL8A-20

TXWL8C-20

TXWL10-20

TXWL11-20

TXWL12-20

TXWL13-R-20

TXW14-20

ST4-40

ST5-40

ST5A-40

ST6A-40

ST8A-40

ST8C-40

ST10-40

ST11-40

ST12-40

ST13-R-40

ST14-40

IN-AGB 1-30

IN-AGB 1-60

IN-AGB 1-90

IN-AGB 1-120

IN-AGB 1-125

IN-AGB 2-170

IN-AGB 2-230

IN-AGB 2-300

IN-AGB 3-270

IN-AGB 3-390

IN-AGB 3-500

IN-AGB 4-600

IN-AGB 4-800

IN-AGB 4-1000

IN-AGB 4-1500

IN-AGB 4-2000

By-pass setting/

By-pass Öffnungsdruck/

By-pass

0.8 bar

1.5 bar

blocked

TXW8A-20

2

B

4

IN 390

Ordering example elementBestellbeispiel ElementExemple de commande de l’élément

Ordering example filterBestellbeispiel FilterExemple de commande de filtre

Std 1

TXW8A-20

2

T

3

B

4

B

5

Note: Filter with LEIF® element and sleeve.Filter mit LEIF®-Element und Filterkorb.Filtre avec l’élément LEIF® et enveloppe métallique.

Note: Spare LEIF® element: no sleeve included. Ersatz LEIF®-Element ohne Filterkorb. Pièce detachée l’élément LEIF®: sans enveloppe métallique.

In case of non LEIF®, delete L in code/Im falle von keine LEIF®, L streichen im Code/

Si pas de LEIF®, supprimer L en code

4

Seal material/

Dichtungen/

Joints code

BBuna (NBR)

N

V

Neoprene (CR)

Viton (FPM)

No Diffuser Ohne Auslaufrohr Sans bac d’ecoulement

Diffuser for ≥ 3-270Auslaufrohr für ≥ 3-270Bac d’ecoulement pour ≥ 3-270

HAMMELMANN Artikel-Nr. / Code no. / Référénce no.: 04.00995.0177Einbausatz / Insert / Partie intérieur IN-AGB1-125

8

ORDERING INFORMATION / BESTELLDATEN / COMMENT PASSER VOTRE COMMANDE

G l o b a l F i l t r a t i o n T e c h n o l o g y

Due to continuous product improvement published data and specifications are subject to change without notice. / Aufgrund Produkt-Verbesserungen können Daten und Spezifikationenohne Mitteilung geändert werden. / En fonction de l’évolution technique du matériel, nous nous réservons le droit de modifier cette documentation sans préavis.

Parker Filtration BVParker ArlonFilter Division EuropeStieltjesweg 86827 BV ArnhemThe NetherlandsPhone: +31 26 3760376Fax: +31 26 3643620E-mail: [email protected]

Parker Hannifin plcFilter Division Europe HQShaw Cross Business ParkDewsbury, West YorkshireWF12 7 RD UKPhone: +44 1924 487000Fax: +44 1924 487038E-mail:[email protected]

Parker Hannifin OyFinn-FilterFilter Division EuropeSalmentie 260FIN - 31700 Urjala As.FinlandPhone: +358 3 54100Fax: +358 3 [email protected]

HAMMELMANN Artikel-Nr. / Code no. / Référénce no.: 04.00995.0177Einbausatz / Insert / Partie intérieur IN-AGB1-125

FEATURES AND BENEFITS

• Designed for return line filtration• Flow direction from in to out• Magnetic pre-filtration• Simple and effective full flow

by-pass• Wide range of removal ratings:

• GDL - glass fibre• XX - cellulose• S - stainless steel wire mesh

• Funnel or diffuser to avoid foaming• Option: LEIF ®

Insert filterEinbaufilterParties intérieur es intégrées

Model IN-AGB

MERKMALE UND VORTEILE

• Model für Rücklauffilterung• Durchflussrichtung von innen

nach aussen• Magnetische Vorfilterung• Einfache und effektive By-pass-

Konstruktion• Filterfeinheiten in:

• GDL - Glasfaser• XX - Zellulose• S - Edelstahlgewebe

• Auslaufrohr zur Verhütung von Schaumbildung

• Option: LEIF ®

AVANTAGES ET BÉNÉFICES

• Pour filtration sur circuit de retour• Sens de filtration de l’intérieur

vers l’extérieur• Préfiltration magnétique• Dérivation by-pass simple et efficace• Gamme étendue de finesses de

filtration en:• Fibre de verre - GDL• Cellulose - XX• Maille en acier inoxydable - S

• Bac d’écoulement anti-mousse enoption

• Option: LEIF ®

HAMMELMANN Artikel-Nr. / Code no. / Référénce no.: 04.00995.0177Einbausatz / Insert / Partie intérieur IN-AGB1-125

CATERPILLAR / ZEPPELIN: Service-Vertretungen Auf Grund dessen, dass CATERPILLAR keine Service-Handbücher mehr zur Verfügung stellt, möchten wir Ihnen helfen, den für Sie zuständigen Kundendienst bzw. die zuständige Service-Vertretung zu ermitteln. Hierzu laden Sie bitte im Internet die Homepage von CATERPILLAR:

W W W . C A T . C O M Nach der Auswahl „Find your dealer“ öffnet sich ein Untermenü, wo Sie sich den zuständigen „Kundendienst“ anzeigen lassen können.

CATERPILLAR Service Partners Due to the fact that CATERPILLAR no longer supply a CATERPILLAR Dealer Directory with their engines, we would like to support you to locate your closest service partner. Please select the homepage of CATERPILLAR:

W W W . C A T . C O M and click on “Find your dealer” to access your nearest service partner.

CATERPILLAR: Service après vente Étant donné que CATERPILLAR ne fournit plus un manuel y contenant un relevé des distributeurs CATERPILLAR avec leurs moteurs diesel, nous vous prions de localiser l’adresse de votre distributeur le plus proche comme suit: Veuillez visiter le site WEB de CATERPILLAR:

W W W . C A T . C O M et cliquer sur «Find your dealer» pour trouver le distributeur le plus proche.

CATERPILLAR: Servicio post-venta Debido a que CATERPILLAR no dispone más de un libro directorio, le indicamos a continuación el modo en el que Usted puede consultar de la manera más eficaz, que distribuidor le corresponde en base a su cercania. Para ello visite la página web de CATERPILLAR:

W W W . C A T . C O M Selecione “Find your dealer” encontrará usted el distribuidor más cercano.

SELF5420 E, A, O, D

Effective with sales to the first user on or after March 1, 2008

CATERPILLAR LIMITED WARRANTYNew 3000 Family, C0.5 through C4.4 and ACERT Industrial Engines

Worldwide

Caterpillar Inc. or any of its subsidiaries (“Caterpillar”)warrants new 3000 Family, C0.5 through C4.4 andACERT industrial engines sold by it, to be free fromdefects in material and workmanship. ACERT industrialengines refer to the C6.6, C7, C9, C11, C13, C15, C18,C27, and C32 engine models.

This warranty does not apply to engines sold for use inmarine applications, engines in machines manufacturedby Caterpillar, or Caterpillar brand batteries. Theseproducts are covered by other Caterpillar warranties.

This warranty is subject to the following:

Warranty PeriodThe standard warranty period for new 3003, 3011, 3013,3014, 3024, C0.5, C0.7, C1.1, C1.5, C1.6, and C2.2engines used in mobile agricultural, industrial,locomotive and petroleum application (excludingPetroleum Power Systems) is 24 months or 2000 hours,whichever occurs first (with the first 12 months atunlimited hours) after date of delivery to the first user.

The standard warranty period for new 3034, 3044, 3054,3056, C3.4, C4.4, and C6.6 engines used in mobileagricultural, industrial, locomotive and petroleumapplication (excluding Petroleum Power Systems) is 24 months or 3000 hours, whichever occurs first (withthe first 12 months at unlimited hours) after date ofdelivery to the first user.

The standard warranty period for new C7, C9, C11, C13,C15, C18, C27, and C32 engines used in industrialapplication is 24 months or 3000 hours, whicheveroccurs first (with the first 12 months at unlimited hours),and 24 months for mobile agricultural applications, afterdate of delivery to the first user.

The standard warranty period for rotating electrics (i)used on new 3000 Family, C0.5 through C4.4 and C6.6engines is 12 months from date of engine delivery to the

first user, and (ii) used on new C7, C9, C11, C13, C15,C18, C27, C32 engines is 24 months or 3000 hours,whichever occurs first (with the first 12 months at un-limited hours) after date of engine delivery to the first user.

The standard warranty period for Petroleum PowerSystems is 12 months after date of delivery to the first user.

Extended WarrantyFor new 3034, 3044, 3054, 3056, C3.4, C4.4, and C6.6engines:

• Low Usage: In cases where the engine use does notexceed 500 hours per year, the warranty period isextended for an additional year or until the engine usereaches a total of 1500 hours, whichever occurs first,after date of delivery to the first user.

For all new 3000 Family, C0.5 through C4.4, and ACERTengines:

• Major Components: A major components extendedwarranty applies solely to the following components:cylinder block casting, cylinder head casting,crankshaft (excluding bearings), camshaft andconnecting rods. These parts are warranted againstdefects in material and workmanship for 36 monthsafter date of delivery to the first user. This warranty runsconcurrently with the standard warranty period.

Caterpillar ResponsibilitiesIf a defect in material or workmanship is found during thestandard warranty period or the extended warrantyperiod if applicable, Caterpillar will, during normalworking hours and through a place of business of aCaterpillar dealer or other source approved byCaterpillar:

• Provide (at Caterpillar’s choice) new, Remanufacturedor Caterpillar-approved repaired parts or assembledcomponents needed to correct the defect.

Note: Items replaced under this warranty become theproperty of Caterpillar.

• Replace lubricating oil, filters, coolant and other serviceitems made unusable by the defect.

• Provide reasonable or customary labor needed tocorrect the defect, including labor to disconnect theproduct from and reconnect the product to its attachedequipment, mounting, and support systems, if re-quired, provided that (i) for new 3003, 3011, 3013,3014, 3024, C0.5, C0.7, C1.1, C1.5, C1.6, and C2.2engines, labor to disconnect and reconnect theproduct is provided up to 10 hours (labor to disconnectand reconnect the product in excess of 10 hours is theuser’s responsibility), and (ii) for new 3034, 3044, 3054,3056, C3.4, C4.4, and C6.6 engines, the labor to dis-connect and reconnect the product is provided up to15 hours (labor to disconnect and reconnect the productin excess of 15 hours is the user’s responsibility).

For new 3000 Family and C0.5 through C7 engines:

• Provide travel labor, up to four hours round trip, if in theopinion of Caterpillar, the product cannot reasonablybe transported to a place of business of a Caterpillardealer or other source approved by Caterpillar (travellabor in excess of four hours round trip, and any meals,mileage, lodging, etc. is the user’s responsibility).

For new C9, C11, C13, C15, C18, C27, and C32 engines:

• Provide reasonable travel expenses for authorizedmechanics, including meals, mileage, and lodgingwhen Caterpillar elects to make the repair on-site.

User ResponsibilitiesThe user is responsible for:

• Providing proof of the delivery date to the first user.

(continued on reverse side)

• Labor costs, except as stated under “CaterpillarResponsibilities”.

• Travel expenses not covered under “CaterpillarResponsibilities”.

• All costs associated with transporting the product toand from the place of business of a Caterpillar dealer orother source approved by Caterpillar.

• Premium or overtime labor costs.

• Parts shipping charges in excess of those that are usualand customary.

• Local taxes, if applicable.

• Costs to investigate complaints, unless the problem is caused by a defect in Caterpillar material orworkmanship.

• Giving timely notice of a warrantable failure andpromptly making the product available for repair.

• Performance of the required maintenance (including useof proper fuel, oil, lubricants and coolant) and itemsreplaced due to normal wear and tear.

• Allowing Caterpillar access to all electronically storeddata.

LimitationsCaterpillar is not responsible for:

• Failures resulting from any use or installation whichCaterpillar judges improper.

• Failures resulting from attachments, accessory itemsand parts not sold or approved by Caterpillar.

• Failures resulting from abuse, neglect and/or improperrepair.

• Failures resulting from user’s delay in making theproduct available after being notified of a potentialproduct problem.

• Failures resulting from unauthorized repair oradjustments, and unauthorized fuel-setting changes.

• Damage to parts, fixtures, housings, attachments, andaccessory items, which are not part of the engine.

SELF5420

For products operating outside of Australia, Fiji, Nauru, New Caledonia, New Zealand,Papua New Guinea, the Solomon Islands and Tahiti, the following is applicable:

NEITHER THE FOREGOING EXPRESS WARRANTY NOR ANY OTHER WARRANTYBY CATERPILLAR, EXPRESS OR IMPLIED, IS APPLICABLE TO ANY ITEMCATERPILLAR SELLS, WHICH IS WARRANTED DIRECTLY TO THE USER BY ITSMANUFACTURER.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER WARRANTIES, EXPRESSOR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESSFOR A PARTICULAR PURPOSE, EXCEPT CATERPILLAR EMISSION-RELATEDCOMPONENTS WARRANTIES FOR NEW ENGINES, WHERE APPLICABLE.REMEDIES UNDER THIS WARRANTY ARE LIMITED TO THE PROVISION OFMATERIAL AND SERVICES, AS SPECIFIED HEREIN.

CATERPILLAR IS NOT RESPONSIBLE FOR INCIDENTAL OR CONSEQUENTIALDAMAGES.

CATERPILLAR EXCLUDES ALL LIABILITY FOR OR ARISING FROM ANYNEGLIGENCE ON ITS PART OR ON THE PART OF ANY OF ITS EMPLOYEES,AGENTS OR REPRESENTATIVES IN RESPECT OF THE MANUFACTURE OR SUPPLYOF GOODS OR THE PROVISION OF SERVICES RELATING TO THE GOODS.

IF OTHERWISE APPLICABLE, THE VIENNA CONVENTION (CONTRACTS FOR THEINTERNATIONAL SALE OF GOODS) IS EXCLUDED IN ITS ENTIRETY.

For personal or family use engines operating in the USA, its territories and possessions,some states do not allow limitations on how long an implied warranty may last nor allowthe exclusion or limitation of incidental or consequential damages. Therefore, thepreviously expressed exclusion may not apply to you. This warranty gives you specificlegal rights and you may also have other

rights, which vary by jurisdiction. To find the location of the nearest Caterpillar dealer orother authorized repair facility, call (800) 447-4986. If you have questions concerning thiswarranty or its applications, call or write:

In USA and Canada: Caterpillar Inc., Engine Division, P.O. Box 610, Mossville, IL61552-0610, Attention: Customer Service Manager, Telephone (800) 447-4986. Outsidethe USA and Canada: Contact your Caterpillar dealer.

For products operating in Australia, Fiji, Nauru, New Caledonia, New Zealand, Papua NewGuinea, the Solomon Islands and Tahiti, the following is applicable:

THIS WARRANTY IS IN ADDITION TO WARRANTIES AND CONDITIONS IMPLIEDBY STATUTE AND OTHER STATUTORY RIGHTS AND OBLIGATIONS THAT BY ANYAPPLICABLE LAW CANNOT BE EXCLUDED, RESTRICTED OR MODIFIED(“MANDATORY RIGHTS”). ALL OTHER WARRANTIES OR CONDITIONS, EXPRESSOR IMPLIED (BY STATUTE OR OTHERWISE), ARE EXCLUDED.

NEITHER THIS WARRANTY NOR ANY OTHER CONDITION OR WARRANTY BYCATERPILLAR, EXPRESS OR IMPLIED (SUBJECT ONLY TO THE MANDATORYRIGHTS), IS APPLICABLE TO ANY ITEM CATERPILLAR SELLS WHICH ISWARRANTED DIRECTLY TO THE USER BY ITS MANUFACTURER.

TO THE EXTENT PERMITTED UNDER THE MANDATORY RIGHTS, IF CATERPILLARIS THE SUPPLIER TO THE USER, CATERPILLAR’S LIABILITY SHALL BE LIMITEDAT ITS OPTION TO (a) IN THE CASE OF SERVICES, THE SUPPLY OF THE SERVICESAGAIN OR THE PAYMENT OF THE COST OF HAVING THE SERVICES SUPPLIEDAGAIN, AND (b) IN THE CASE OF GOODS, THE REPAIR OR REPLACEMENT OF THEGOODS, THE SUPPLY OF EQUIVALENT GOODS, THE PAYMENT OF THE COST OFSUCH REPAIR OR REPLACEMENT OR THE ACQUISITION OF EQUIVALENTGOODS.

CATERPILLAR EXCLUDES ALL LIABILITY FOR OR ARISING FROM ANYNEGLIGENCE ON ITS PART OR ON THE PART OF ANY OF ITS EMPLOYEES,AGENTS OR REPRESENTATIVES IN RESPECT OF THE MANUFACTURE OR SUPPLYOF GOODS OR THE PROVISION OF SERVICES RELATING TO THE GOODS.

CATERPILLAR IS NOT LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGESUNLESS IMPOSED UNDER MANDATORY RIGHTS.

IF OTHERWISE APPLICABLE, THE VIENNA CONVENTION (CONTRACTS FOR THEINTERNATIONAL SALE OF GOODS) IS EXCLUDED IN ITS ENTIRETY.

This warranty covers every major component of the products. Claims under this warranty should be submitted to a place of business of a Caterpillar dealer or other source approved by Caterpillar. For further information concerning either the location to submit claims or Caterpillar as the issuer of this warranty, write Caterpillar Inc., 100 N.E. Adams St., Peoria, IL USA 61629.

SIHISuperNova Programme Range: ZLND Volute casing pump complying with EN 733 / DIN 24255*

For local contact details: www. sterlingfluidsystems.com

In the search to improve continuously its products, Sterling Fluid Systems reserves the right to modify its

products at any time without prior notice

(Sterling Fluid Systems BV) 2001

Operating instructions Safety issues Chapter 1 Safety instructions and compliance Intended application Chapter 2 Application, description

Planning the installation Chapter 3 Requirements, piping system, accessories

Unpacking, storage, transport Chapter 4 Supply, interim storage, corrosion protection

Installing the pump Chapter 5 Assembly at site, tools, checks

Start-up and shut-down Chapter 6 Important requirements

Maintenance, dismantling, assembly Chapter 7 Intervals, cleaning

Troubleshooting Chapter 8 If something does not work

Technical data Chapter 9 Dimensions, permissible values Annex Chapter 10 Technical data, dimensions table, sectional drawings * With certain exceptions – see Technical Catalogue Attention: Both the pump and/or the pump set must be installed and commissioned by qualified technical personnel only and these installation, commissioning and operating instructions must be strictly observed. Failure to do so could result in:

• danger to you and your colleagues, • the pump or the pump unit may be damaged,

Note that the manufacturer is not liable for damages resulting from failure to observe these instructions. Please be aware of your responsibility to your colleagues when working on the pump or the pump set!

Safety instructions marked with included in this Operating Instructions and in the Supplementary Operating Instructions, which must be attached to this Operating Instruction, have to be considered in particular when operating this pump in potentially explosive atmospheres!

HAMMELMANN Code no.: 04.03226.0769Type 32-200

Safety issues Page 1 of 3 Chapter 1

For local contact details: www. sterlingfluidsystems.com

In the search to improve continuously its products, Sterling Fluid Systems reserves the right to modify its

products at any time without prior notice.

(Sterling Fluid Systems BV) 2001

1. Safety This operating manual gives basic instructions, which must be observed during installation, operation and maintenance of the pump. It is therefore imperative that this manual is read by the responsible personnel / operator(s) prior to assembly and commissioning. It must always be kept available at the site of pump installation. It is not only the general safety instructions contained in this chapter “Safety” which must be observed, but also the specific information provided in the other chapters. 1.1 Identification of safety symbols in the operating instructions Safety symbols are given in these operating instructions. Non compliance with these would affect safety and are identified by the following symbol

Danger symbol as per DIN 4844-W9 (ISO 3864 - B.3.1)

Or in case of danger of electric current with:

Danger symbol as per DIN 4844 W-8 (ISO 3864 - B.3.6)

The word

ATTENTION identifies those safety regulations where non-compliance may pose a danger to the pump and its function. It is imperative that the appropriate safety information is attached to the pump/pump set, for example: • an arrow indicating the direction of rotation • symbols indicating fluid connections

• the identification plate and that these are kept legible. 1.2 Qualification and training of personnel The personnel responsible for operation, maintenance, inspection and assembly must be adequately qualified. The scope of responsibility and supervision of the personnel must be exactly defined by plant management. If the staff do not have the necessary knowledge, they must be trained and instructed. This task may be performed by the machine manufacturer or supplier on behalf of the plant management. Moreover, plant management must ensure that the contents of the operation instructions are fully understood by plant operators and other relevant personnel such as maintenance staff. 1.3 Hazards in case of non compliance with safety instructions Non compliance with the safety instructions may result in risk to personnel as well as to the environment and the pump/pump set and result in the loss of any right to claim damages. For example, non-compliance may result from, or lead to, the following: • failure of important functions of the pump/pump

set/plant • failure of specified procedures of maintenance

and repair • exposure of people to electrical, mechanical

and chemical hazards • danger to the environment owing to hazardous

substances being released.

HAMMELMANN Code no.: 04.03226.0769Type 32-200

Safety issues Page 2 of 3 Chapter 1

For local contact details: www. sterlingfluidsystems.com

In the search to improve continuously its products, Sterling Fluid Systems reserves the right to modify its

products at any time without prior notice.

(Sterling Fluid Systems BV) 2001

1.4 Compliance with regulations relating to safety at work When operating the pump the safety instructions contained in this manual, the relevant national accident prevention regulations and any other service and safety instructions issued by plant management must be observed. 1.5 Safety instructions relating to operation • If high or low temperature pump/pump set

components involve hazards, steps must be taken to avoid accidental contact.

• Guards for moving parts (e.g. couplings) must not be removed from the pump/pump set while in operation.

• Any leakage of hazardous (e.g. explosive, toxic, hot) fluids (e.g. from the shaft seal) must be drained safely so as to prevent any risk to persons or the environment. Statutory regulations are to be complied with.

• Hazards from electricity are to be avoided by the user (see for example the VDE-specifications and the bye-laws of the local power supply utilities).

1.6 Safety instructions relevant for maintenance, inspection and assembly work It is the plant manegement’s responsibility to ensure that all maintenance, inspection and assembly work is performed by authorized personnel who have adequately familiarised themselves with the subject matter by studying this manual in detail. Any work on the machine must only be performed when it is at a standstill. It is imperative that the procedure for shutting down the machine described in this manual is followed. Pumps and pump sets, which convey hazardous media, must be decontaminated. On completion of the work all safety and protective guards must be re-installed and made

operative again. Prior to re-starting the machine, the instructions listed under “first commissioning” are to be observed. 1.7 Safety instructions for the use in

areas with explosion hazard

In this section information is given for operation in areas where an explosion hazard exists. 1.7.1 Complete pump sets If the pump is combined with other mechanical or electrical components in one set, the category of the complete unit will correspond, based upon the Directive 94/9/EC, only to that category with which all of its components comply. Note: These comments are of particular importance when pumps, which conform to a given category of Directive 94/9/EC, are powered by a driver which is not in the same category. Although the pump may bear the Ex sign, the set should not be used in areas with an explosion hazard when the motor is not classified for this application. This means that plant management personnel should always check that all elements of the set comply with the Directive 94/9/EC. 1.7.2 Execution of coupling guards Coupling guards that are to be used in areas with an explosion hazard, have to fulfil one of the following criteria: • consist of non-sparking material, e.g. brass. • if they consist of sparking material, e.g. steel

sheet, they must be designed in such a way that the rotating parts will not come in contact with any part of the guard if errors, that could be foreseen, are committed by the user, e.g if a person steps on the guard.

HAMMELMANN Code no.: 04.03226.0769Type 32-200

Safety issues Page 3 of 3 Chapter 1

For local contact details: www. sterlingfluidsystems.com

In the search to improve continuously its products, Sterling Fluid Systems reserves the right to modify its

products at any time without prior notice.

(Sterling Fluid Systems BV) 2001

1.7.3 Monitoring technical parameters

When using pumps in areas with an explosion risk, the operator must check the following parameters regularly: • leakage of shaft seals • bearing temperature • that the pump is always filled with liquid during

operation • that the pump does not operate against a

closed valve for any length of time. The operator must ensure that pumps, which show evidence of abnormal operation, are switched off and not started again until the cause of the abnormal operation has been eliminated. 1.7.4 Avoiding external damage In areas with a risk of explosion the operator must ensure that the pumps and or pump set is not subjected to external impacts e.g by heavy objects. 1.8 Unauthorized alterations and production of spare parts Modifications may be made to the pump/pump set only after consultation with,and written approval from, the manufacturer. Using spare parts and accessories authorized by the manufacturer are in the interests of safety. Use of other parts may exempt the manufacturer from any liability. 1.9 Unauthorized mode of operation The reliability of the pump/pump set can only be guaranteed if it is used in the manner intended and in accordance with the instructions of this manual. The specified limit values must under no circumstances be exceeded.

1.10 Warranty / guarantee Sterling Fluid Systems guarantee satisfactory operation if: • the pump is installed and operated in

compliance with these instructions and in operating conditions approved by Sterling Fluid Systems

• modifications are only undertaken with Sterling Fluid Systems’ written agreement.

HAMMELMANN Code no.: 04.03226.0769Type 32-200

Intended application Page 1 of 3 Chapter 2

For local contact details:

www. sterlingfluidsystems.com

In the search to improve continuously its products,

Sterling Fluid Systems reserves the right to modify its

products at any time without prior notice

(Sterling Fluid Systems BV) 2001

2. Application The pump is to be used only for the operating conditions stated by the customer and confirmed by the supplier. Guarantee is assumed within the scope of the Sterling Fluid Systems conditions of sale. Appropriate application and operating conditions are contained in the attached data sheets. 2.1 Warning of misuse

• The pump may only be used for the

application(s) stated. Otherwise hazards for people and environment may arise.

• Do not exceed fluid density stated.

Otherwise, there is a the danger of motor overload.

• The pump must not be operated beyond its characteristic curve – otherwise there is a danger of cavitation and motor damage.

2.2 Accessories The accessories included in the scope of supply are indicated in the delivery note or in the order confirmation. The corresponding operating and installation instructions are also indicated in the Annex relating to accessories. If it is intended to mount other accessories on the pump or on the pump set, please inform the manufacturer in advance in order that appropriate technical advice can be given.

2.3 Construction and mode of operation

ZLND pumps are horizontal, single-stage volute casing pumps with nominal outputs and flange dimensions meeting EN 733 / DIN 24255. Their back pull out construction allows the disassembly of the complete bearing unit towards the drive side without removing the pump casing from the pipework. ZLND pumps are preferably used when pure or turbid liquids, not containing solid particles, are to be handled. Impurities up to a grain size of 3 mm can be handled, but shorten the service life.

ATTENTION

HAMMELMANN Code no.: 04.03226.0769Type 32-200

Intended application Page 2 of 3 Chapter 2

For local contact details:

www. sterlingfluidsystems.com

In the search to improve continuously its products,

Sterling Fluid Systems reserves the right to modify its

products at any time without prior notice

(Sterling Fluid Systems BV) 2001

2.4 Description Type size

Hydraulic + Bearing

Shaft seal

Material design

Casing gasket

ZLND

32125 to

300500

A• First hydraulic B• Second hydraulic D• Double volute • B Two ball bearings greased for life (2Z) • C Two ball bearings oil lubricated • 2 Oil lubrication configurations with CLO • S One double row angular contact bearing plus one ball bearing, grease lubricated • T One double row ball bearing plus ball bearing, oil lubricated

041: Self-sealed, uncooled packing rings 052: Uncooled packing rings, external seal liquid BJ3,C23,AF3,AX3,AY3,A93:SiC/Carbon, EPDM BJS,C2S,AFS, AXS,AYS,A9S: SiC/ SiC, Viton BJJ,C2J,AFK,AXK,AYK,A9K: SiC/Carbon, Viton

0B: Cast iron GG25 0C: Cast iron GG25, Bronze G-CuSn10 impeller 0E: Cast iron GG25, Stainless steel 1.4408 imp. 4B: Stainless steel 1.4408

2: confined flat gasket of EWP 210 material 4: confined flat gasket of PTFE

A or B 32160, 32200 A 32125 to 200315, 250315 D 200400 to 300500 Alternatively B, C, 2, S or T

Alternatively 041,052,BJ3,C23,AF3,AX3,AY3,A93,BJS,C2S, AFS,AXS,AYS,A9S,BJJ,C2J,AFK,AXK,AYK,A9K

Alternatively 0B, 0C, 0E, 4B

Alternatively 2, 4

Codes AX3, AXS, AXK: are equivalent to AF3, AFS, AFK respectively plus quench Codes AY3, AYS, AYK: are equivalent to AF3, AFS, AFK respectively plus heating Codes A93, A9S, A9K: are equivalent to AF3, AFS, AFK respectively plus external flushing

HAMMELMANN Code no.: 04.03226.0769Type 32-200

Intended application Page 3 of 3 Chapter 2

For local contact details:

www. sterlingfluidsystems.com

In the search to improve continuously its products,

Sterling Fluid Systems reserves the right to modify its

products at any time without prior notice

(Sterling Fluid Systems BV) 2001

Example of a pump designation: 1-3 4 5-7 8-10 11 12 13-15 16-17 18

ZLND 125 250 A C 041 OB 2

2.5 Shaft sealing Depending on the application, different shaft sealing executions are offered (see 2.4) • a stuffing box with lantern ring (executions

041, 052, and optionally 051) or mechanical seals according to DIN 24960 are utilised in the following cases:

• if the pump draws from a suction line, • if the pump is fed by a feed line with a

pressure of less than 0.5 bar or • if the pumped liquid is at or near its boiling

point. Provision of the sealing liquid is as follows: • 041: Internal self sealing ISO 5199 plan 01 • 052: External self sealing ISO 5199 plan 08 • 051: External self sealing ISO 5199 plan 09 • Mechanical seal: ISO 5199 plan 02. API plan

11 • Mechanical seal execution plus external

flushing: ISO 5199 plan 08, API plan 32 Mechanical seal execution plus quench: ISO 5199 plan 09. API plan 62.

Section 2.4 does not contain the codes for all variations of mechanical seals. Where the code is not included or replaced by QQQ, consult the relevant data sheet of the mechanical seal supplier (e.g. special execution of the mechanical sealing in a back to back position).

ATTENTION

Casing gasket

Construction

Shaft sealing Bearings:B,C,S,T or 2

Impeller size

Nominal discharge

Pump series

Hydraulic: A/B/D

HAMMELMANN Code no.: 04.03226.0769Type 32-200

Planning the installation Page 1 of 2 Chapter 3

For local contact details: www. sterlingfluidsystems.com

In the search to improve continuously its products, Sterling Fluid Systems reserves the right to modify its

products at any time without prior notice.

(Sterling Fluid Systems BV) 2001

3.0 Planning the installation 3.1 Piping system • Note the arrows on the pump branches

indicating the direction of flow. • Choose nominal widths of the pipelines

according to the nominal widths of the pump branches or larger ones with the corresponding reductions.

• Flange sealing must not protrude on the inside.

• Ensure that the pipework is clean before installing of the pump.

• Support the pipework in order to avoid distortions at the pump components (risk of damage to pump components)

• Avoid abrupt changes of cross section and direction.

• Where different diameter pipework is to be used, connection should be by eccentric transition pieces. This will avoid the formation of air pockets in the pipework.

• For difficult pumping on the suction side, to stabilise the flow, a pipe length 15 times the diameter of the suction branch should be installed before the suction branch.

• The flow rate in the suction line or inflow line, must not exceed 2 - 3 m/s.

3.1.1 Suction line / inflow line See the sketches below for the optimum layout of pump installation for flow and suction lift operation.

positive suction head operation suction lift operation

Ensure that air pockets cannot be created. Unequal nominal widths of the suction branch and suction line must be compensated by eccentric transition pieces.

Flow straightener

Connection of eccentric pipe transitions It is recommended that a filter is installed in front of the pump with a filter surface of at least 3 times the pipe cross section (approx. 100 meshes/cm²). The suction opening of the suction line should be well below the liquid level, and a strainer should be used. The strainer must be far enough from the bottom to avoid excessive inlet losses, which could impair pumping performance. It is advisable to check that there is no leakage.

ATTENTION

4

4

3

6

1 2

7

1 Eccentric reducer ( suction line ) or

concentric reducer ( feed line )

2 Shut-off valve

3 Suction line

4 Bend

5 Foot valve with suction strainer

6 Check valve

7 Regulating valve

5

Pump installation

HAMMELMANN Code no.: 04.03226.0769Type 32-200

Planning the installation Page 2 of 2 Chapter 3

For local contact details: www. sterlingfluidsystems.com

In the search to improve continuously its products, Sterling Fluid Systems reserves the right to modify its

products at any time without prior notice.

(Sterling Fluid Systems BV) 2001

A shut-off valve should be installed in the feed line. It must be closed for maintenance work. It should be installed in order to avoid air pockets forming in the spindle cap, i.e. with the spindle in a horizontal position or pointing vertically downward. 3.1.2 Discharge line For flow regulation, a valve must be installed behind the pump. If non-return valves are used, they should close smoothly. Pressure shocks must be avoided. 3.1.3 Inlet and outlet connections The various connecting points are shows in the drawings. (See Annex, Chapter 10, point 10.1). 3.1.4 Pressure control For consistent control of pressure, it is advisable to install in the pipework a measuring point in front of, and behind the pump. 3.2 Electrical connections For the drive motor a mains connection is required which complies with the European Regulations and Directives for the Standards in Industry and with the instructions of the local power supply utilities of the country concerned.

HAMMELMANN Code no.: 04.03226.0769Type 32-200

Unpacking, storage, transport Page 1 of 2 Chapter 4

For local contact details: www.sterlingfluidsystems.com

In the search to improve continuously its products, Sterling Fluid Systems reserves the right to modify its

products at any time without prior notice

(Sterling Fluid Systems BV) 2001

4. Unpacking, storage, handling 4.1 Safety measures

• Never stay below the suspended load. • Keep a safe distance while the load is being

transported. • Use only approved lifting appliances, which

are in good condition. • Adjust the length of the lifting appliances in

such a way that the pump and/ or the pump set, is suspended horizontally.

• Do not use the eyebolts on the pump components for lifting the assembled pump or the complete set.

• Do not remove documents, which are attached to the pump.

• Do not remove the protection covers from the pump suction/discharge. Otherwise, there may be a risk of contamination.

4.2 Unpacking Before unpacking, a visual check of the packing is recommended. If transport damage is visible, the extent should be noted on the receipt or on the delivery note. Potential claims must be lodged immediately with the carriers or the insurance company. 4.3 Interim storage If the pump or the pump unit is not installed immediately after delivery, it must be stored free from vibration in a dry room.

4.4 Handling The pump or pump set must be lifted and handled as shown in the following sketches.

Pump without motor