Montageanleitung (DIN 3859-2) / Assembly instruction (DIN ......Montageanleitung (DIN 3859-2) /...

Transcript of Montageanleitung (DIN 3859-2) / Assembly instruction (DIN ......Montageanleitung (DIN 3859-2) /...

11

Montageanleitung (DIN 3859-2) /

Assembly instruction (DIN 3859-2)

Diese Montageanleitung, nach DIN 3859-2 ist gültigfür lötlose Rohrverschraubungen mit Schneidrin-gen nach DIN EN ISO 8434-1 Internationale Norm(DIN 2353 Nationale Norm).

Sie haben sich für CONEXA Rohrverschraubungenentschieden, weil Sie Wert auf dauerhafte Betriebs-sicherheit legen. Aber auch die rationelle Monta-gemöglichkeit spricht für CONEXA.

Wichtig, mit Blick auf obige Norm, sind die nach-folgend beschriebenen Montageabläufe. Die gefor-derte funktionsgerechte Montage, die vom Mon-teur genau nach festgelegten Verfahrensanwei-sungen und nach bestem Gewissen durchzuführensind. Desweiteren sollte vor Beginn jeder Montage,alle Anforderungskriterien, Spezifikationen und dieWahl der Montageart bekannt sein.

Anforderungskriterien wären z.B.:

°Anwendungsbereich: Art des zu verwendetenFluids. Hydraulik,- oder Pneumatikanlage, Ver-fahrenstechnik, Beanspruchung

°Druckbeanspruchung auswählen: Systemdruckoder Druckspitzen, Rücklauf oder Saugleitung.Max. Arbeitsdruck, Max. Durchfluss, Viskosität,sodann ist die Baureihe L/S wählbar.

°Medium: Beständiger Werkstoff ist zu wählen.

°Temperatur: Temperaturbeständigkeit beachten,Betrieb / Stillstand und Umwelt

°Einbauraum: Baureihe „L/S“ entsprechend derEinbauverhältnisse auswählen.

°Umwelt: Beständiger Werkstoff mit ausreichenderKorrosionsbeständigkeit ist auszuwählen.

°Spezifikationen: Endkundenanforderung und Nor-men sind zu berücksichtigen und dabei gilt: DieQualität soll so genau wie nötig und nicht wiemöglich definiert werden.

Mögliche Montageabläufe sind:

°Maschinelle Montage: Wirtschaftlich und bevor-zugte Methode. Wir empfehlen ab Rohr Ø (Size)16 die Montage mit entsprechendem Montage-gerät (elektrohydraulisch) durchzuführen.

°Direkt-Montage: Der Montageprozess wird direktmit den Rohrverschraubungskomponenten durch-geführt. Diese Montage eignet sich nur für kleineAbmessungen und Reparaturarbeiten. Die Direkt-Montage ist nicht wirtschaftlich bei Serienferti-gung!!

Assembly instruction to DIN 3859-2 is valid fornon-soldering compression couplings with cut-ting-rings according to DIN EN ISO 8434-1 inter-nationale norm and DIN 2353 (nationale norm).

You decided for CONEXA tube couplings becauseyou attach great importance to continued opera-tional reliabillity. Another argument for CONEXA isrational assembly of the tube couplings.

Important, to look above mention norm, are thefollowing described “assembly-instruction”Demanded is a functionaly-assembly of fixed pro-cedures. Before beginning with the first assembly,you must check and know all spezification andchoose your assembly-metods.

Design criteria:

°Application range: Type of fluid within thesystem. Hydraulic, – or pneumatic facilities, pro-cess technology, strain.

°Choose the pressure-range: Working-pressure orpressure-peaks, open, return or suction. Max.operating pressure, max. flow rate, viskosity andyou choose the series L/S.

°Fluid: Choose the fluid compatibility.

°Temperature: Choose the operating temperatureof the system. Process / Standstill / Enviromen-tal.

°Build-in space: Choose the series L/S to space-restrictions.

°Enviromental: Choose the material with sufficientcorrosive-compatibility.

°Spezification: Consider the customers require-ment and the norm.

The quality should be defined as exactly asnecessary.

Assembly proposals:

°Mechanical-assembly: Economical and privile-ged methods. We recommend for tubes sizes > Ø 16 to assembly with hydraulic assembly-device.

°Direct-assembly: Direct-assembly within the uni-ons. This assembly is good forr small dimensionsand maintenance. The direct-assembly is noteconomical for production!!

Montageanleitung (DIN 3859-2) /

Assembly instruction (DIN 3859-2)

°Werkstoffkombinationen: Beider Auswahl der Werkstoffe istzu berücksichtigen, dass dieVerschraubungskomponentenauf das Rohr abgestimmt seinmüssen (z. B. die Festigkeits-bedingungen und der Lieferzu-stand). Außerdem sind bei derWahl der Werkstoffe das Fluidin der Rohrleitung, der zuläs-sige Betriebsdruck, die Tempe-ratur sowie andere einwirkendeKräfte wie, Wärmespannun-gen, Erschütterungen, schwin-gende Beanspruchung, Druck-stöße usw. zu berücksichtigen.

°Material-Combination: Whenchoose the range of materialtake into consideration that thefitting-components-materialcoresponds with the tube. Thisis important for material-strength-condition and the deli-very quality. Besides the choo-se at the material consideringthe flow-substance within thepipeline, operating-pressure,temperature as well as some-one else can effect by heat-energy, vibrating stress andshock wave effects, etc.

We recommend the followingmaterial-combinations:

°Rohrqualität: Wir empfehlendie Verwendung von Standard-nahtlosen Präzisionsrohren.Bei Rohrwerkstoff aus Stahl,Ausführungsart, nahtlos kalt-gezogen.Bei Rohrwerkstoff aus Edel-stahl, Ausführungsart, nahtloskaltgezogen, zunderfrei wär-mebehandelt.

°Tube quality: We recommendto use the standard seamlesstubes. The seamless carbonand stainless tubes, annealed,free from scale and colddrawn.

Montageanleitung (DIN 3859-2) /

Assembly instruction (DIN 3859-2)

We recommend for tubes Ø 20,30, 35, 38 and 42 to be assem-bled in vice with preassembly-tools.

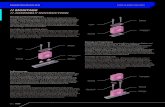

Cut the pipe square. An angu-lar-tolerance deviation of 0,5°relative to the tube axis ispermissible.

Lightly deburr the tube-endsinside and outside tube edge-donot temper. Clean the tube. Chamfer up to 0,2x45° permis-sible.

Attention!Every form-deviation at thetube end, or wrong burr reducethe service-life and the tight-ness of the union.

Spray cutting-rings, threadsand cone of the fitting-bodyand the internal thread of thenuts with lubricant:

-vegetable oil for carbon steel

-CONEXA-Assembly-Spray forstainless steel. The sprayreduced the assembly-power,prevent cold-welding of thecomponents and spare them.

Slip the cutting-ring and nutonto the correct position on theend of the tube.

Montageanleitung (DIN 3859-2) /

Assembly instruction (DIN 3859-2)

Attention!Please see chart from tube-manufacture.Apply by thin-walled or softmetal tube reinforcing slee-ves, then:

- by low working pressurethin-walled tubes often used.Here are material strengthand wall thickness ofteninsufficient to withstand theradial forces of the cutting-ring generated during assem-bly. Which cause of tube-reduction and leakages.

The assembly of reinforcingsleeves is follow:

- the correct length of thetube under observation thestandard tube-preparation(“look to point1”) please insert the reinfor-cing sleeves like shown andusing a hammer (hard rubberor plastic) and push it insideup to the tube-end.

Tabular summery for usingreinforcing sleeves. This tabu-lary is for carbon-steel tubes,material St 37.4 and for stain-less-steel tubes, material1.4571 or 1.4541.

Not described wall thickness –area or tube-material requireone first-sample-test-assembly.Functional testing!!

Montageanleitung (DIN 3859-2) /

Assembly instruction (DIN 3859-2)

°1.4 Starting torque fordirect assembly:

Press tube-end firmly into thefitting-body until the conestops on bearing surface.(photo 1.4-a).

Attention!When the tube-end do not fitwith the bottom of the body –no cut into the tube!

Screw the nut on manuallyuntil finger-tight. (photo 1.4-b)

Mark position of the nut andunion-socket and later youcan control the prescribedturns.

Tighten the nut 1,5 turns.

Union-socket fixed with span-ner.

Attention!We recommend to use spannerextension for tube diameter > Ø 20mm.(photo 1.4-c)Any devating number of tigh-tening turns reduces the nomi-nal pressure and the service-life of the union, which causesleakages or slipp-out of thetube.

°1.5 Assembly check:

Loosen the nut. Take out ofthe union the tube with cut-ting-ring.Check there is a visible-collarin front of the cutting-edge.

The cutting-ring may turn onthe tube but should not becapable of axial displace-ment.

Montageanleitung (DIN 3859-2) /

Assembly instruction (DIN 3859-2)

°1.6 Re-assembly:

Each time the fitting is disas-sembled, the nut must be re-tightened firmly using thesame torque as required fordirect-assembly. (See 1.4).The body must be held rigid.The union-socket fixed withspanner.

2. Assembly in vice withpreassembly-tools

“VOMO” as well as final-assembly in the fitting-socket:

°2. Pre-assembly-cone / socket

The pre-assembly-cone mustbe checked regularly, after50. pre-assemblies with cone-gauges.The surface-treatment of theVOMO-Cone “internal” mustbe without any damage “e.g.no one groove or burr”.

Attention!Please control periodical yourpre-assembly-cones and youavoid any wrong assembly.

°2.1 Further procedure andout-Look:

- Point 1= Standard tube-preparation, minimum-lengthfor the tubes

- Point 1.2= Assembly-Lubricant and

- Point 1.3= Reinforcingsleeves

Montageanleitung (DIN 3859-2) /

Assembly instruction (DIN 3859-2)

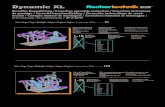

°2.2 Pre-assembly in vice:

Press tube-end firmly manual-ly into the preassembly-body-cone until the stop in the bot-tom.(Photo 2.2-a)Attention!When the tube-end do not fitwith the bottom of the body –no cut into the tube!

Screw the nut on manuallyuntil finger-tight. (Photo 2.2-b)

Mark position of the nut andlater you can control the pre-scribed turns.

° Starting torque for pre-assembly:

Tighten the nut 1,25 turns= (pre-assembly). (Photo 2.2-c)

Attention!We recommend to use spannerextension for tube diameter > Ø 20mm.(Photo 2.2-c)Any devating number of tigh-tening turns reduces the nomi-nal pressure and the service-life of the union, which causesleakages or slipp-out of thetube.

Montageanleitung (DIN 3859-2) /

Assembly instruction (DIN 3859-2)

°2.4 Repeated assembly afterthe pre-assembly:

Each time the tube connec-tion-line is disassembled,spray lubricant repeated onall striking surfaces “e.g.threads/Cutting-Rings”.

The re-assembly must be per-formed with the same torqueas initial assembly.

Screw the nut on manuallyuntil finger-tight.

The body must be held rigid.Recommended to use spanner.

°2.5 Final-assembly:

For final assembly, screw thetube-end back together withthe coupling.

Tighten the nut with a span-ner until there is a clearincrease in resistance.Mark the position of the nutand later you can control theprescribed turns.

Then tighten the nut approx1/4 turn, over the point offorce feeling. Use a spannerto hold the body.This is the final stage of theassembly.

Attention!We recommend to use a span-ner extension for tube diame-ter > Ø 20mm. (Chart 2.5)Any devating number of tigh-tening turns reduce the nomi-nal pressure and the service-life of the union, which cau-ses leakages or slipp-out ofthe tube.

Montageanleitung (DIN 3859-2) /

Assembly instruction (DIN 3859-2)

3. Pre-assembled standpipecouplings:

All couplings are deliveredpre-assembled from the fac-tory.The final-assembly is perfor-med in the appropriate fitting-body.

Standpipe fittings are:

EVT, EVL, EVGE; EVW,etc

°Final-assembly of pre-assem-bled standpipe couplings:

Standpipes are generally sup-plied with pre-assemblednut/cutting-rings.

Spray lubricant on all strikingsurface, the internal threads ofthe nuts, the cutting-rings andthe threads of the couplingsagain.

Screw the nut on manuallyuntil finger-tight.

Tighten the nut with a spanneruntil there is clear increase inresistance.Mark the position of the nutand later you can control theprescribed turns.

Then tighten the nut approx 1/4 turn, over the point of forcefeeling.Use a spanner to hold thebody.

This is the final stage of theassembly.

Attention!We recommend to use a span-ner extension for tube diame-ter > Ø 20mm.Any devating number oftightening turns reduce thenominal pressure and theservice-life of the union, whichcauses leakages or slipp-outof the tube.

Montageanleitung (DIN 3859-2) /

Assembly instruction (DIN 3859-2)

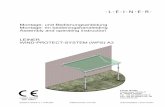

Machine-assembly(pre-assembly):

Characteristics and procedure:Compared to manual-assemblyit greatly reduces assemblytime, effort and cost. Themachine-assembly is efficient(quick operation-time of pre-assembly), safe and reliable (aperfect pre-assembly reducesthe risk of leaking) and flexible.The tool range cover all tubesizes from Ø 6mm until Ø42mm.

Assembly-device:

The norm describes no specialassembly-machine. Each com-pany has the free choice of theassembly-machine.Every assembly-machine has tobe provided with a pressuretable. For the pre-assemblyobserve the pressure setting forcorresponding tube diameters,material and types of cutting-ring “D/DPR/B4”.The cone must be checked regu-larly and the surface treatment”internal” must be without anydamage, no groove or burr etc

Pre-assembly with the assemb-ly device:

Cut the correct length of thetube, (please note the 90°-cut)and slip the cutting-ring withnut into the correct position.(Photo 5) Spray the cutting-ring, the tube and the assembly-cone with lubricant. Choose thetools, observe the pressure set-ting. Press the tube-end firmlymanually into the assembly-cone until is stops on bottomsurface. Hold the tube firmlyand press the button “START”.Follow the assembly-check atpoint 1.5!