GEVIS als Baustein zur Umsetzung der GEVER Verordnung - Architekturboard UVEK 05.04.2013

00 Titel PE4 05.04.2013 13:19 Uhr Seite 1 Volume 103 … · 2017. 6. 12. · ten have a marked...

Transcript of 00 Titel PE4 05.04.2013 13:19 Uhr Seite 1 Volume 103 … · 2017. 6. 12. · ten have a marked...

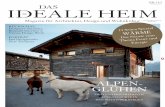

4/2013Volume 103 www.kunststoffe-international.com

Magazine for Plastics

Kunststoffe international·

Vo

lum

e 103

·Issu

e 4/2013

SPECIALON COLORING

PLASTICSfrom page 8

ExtrusionA Special Coating

Protects Twin Screwsagainst Wear 50

Injection MoldingIntegrated

Material Recycling 34

00_Titel_PE4 05.04.2013 13:19 Uhr Seite 1

DIRK SCHÖNING

INNO GAUL

Polyamides are an important class ofengineering plastics. For the vastmajority of applications in which

they are used, these plastics are coloredblack or left in their natural color, espe-cially in the automotive sector. Othermarket segments for polyamides includeelectrical accessories, such as plugs, andfood packaging film. A key reason forchoosing polyamides is their excellentprice/performance ratio. Their high im-pact strength and elastic modulus valuescoupled with excellent thermal stabilitymake them particularly suitable for engi-neering applications in which good elec-trical properties are required. Their high

filler loading capacity permits the use ofreinforcing materials such as glass fibers,which significantly increases their rigid-ity and strength values. Polyamide (PA)6and 66 are most commonly used to pro-duce electrical and electronic plugs andvarious housing components.

To achieve clear recognition in a com-petitive environment, many components,especially housing parts, are colored inthe house color of the original equipmentmanufacturer (branding).

The Right Colorant

To ensure that coloration of the materi-als described leads to the desired, repro-ducible result, it is very important to se-lect the right colorants.

First and foremost, these colorantsmust comply with thermal stability re-quirements, since processing tempera-tures in injection molding can reach upto 300°C. In the mold, additional short-term temperature peaks considerably

Color-Stable at High Temperatures

Polyamides. A heat-stable color system can only be achieved with a certain num-

ber of colorants. This is because many colorants reach their thermal stability limits

at the high processing temperatures encountered.

Polyamide 6, coloredwith a new pigmentcarrier system, doesnot change its color,even after exposureto a processing tem-perature of 320°C(left: with a PA6-based carrier system,right: with a newcarrier system) (figures: Akro-Plastic)

Fig. 1. Formation of the reactive center on the carbonamide group

16

SPEC I A L

© Carl Hanser Verlag, Munich Kunststoffe international 4/2013

Fig. 2. Different base structures of the pigments and dyes used in polyamide coloration

a) b) c) d)

Translated from Kunststoffe 4/2013, pp. 27–29Article as PDF-File at www.kunststoffe-international.com; Document Number: PE111312

w w

ViePhow e

Multi-T

16-19_PE111312_PE4 08.04.2013 11:09 Uhr Seite 16

>

Co l o r ing P l a s t i c s SPEC I A L

higher than 300°C also occur. These de-pends on the design of the component,i. e. how many wall thickness and flowpath transitions there are and what pres-sures and injection rates are used.

Many colorants succumb to hightemperature at an early stage. The pig-ment breaks down, leading to undesir-able discoloration of the component.This frequently shows up in the form ofdark, brownish streaks or loss of opacity,since some pigments go into solu-tion under the prevailing conditions.Many colorants lose their color effect en-tirely as a result of the decompositionprocess.

Some 15 years ago, this problem couldbe solved very easily and effectively withlow-cost heavy metal pigments (lead- orcadmium-based).But the use of these col-orants is no longer desirable in light of to-day’s increased environmental awareness.A possible substitute has been found withthe introduction of the rare earth metal,cerium sulfide, as a colorant. This pig-ment family – with shades varying fromBurgundy red through red to a very bril-liant orange – is highly suitable for col-oration of polymers right into the high-temperature range and therefore also for

polyamide. But its price is relatively highand its market availability restricted. Thispigment class also has very limited chem-ical resistance.

Generally speaking, all types of inor-ganic, i. e. in the broadest sense of theword mineral, pigments can be used forpolyamide coloration. But when bright,brilliant colors are required, the limita-tions of this colorant class are very quick-ly exposed.

Colorists must therefore turn to organ-ic, i.e. synthetically produced, pigmentsand dyes. Depending on their properties,i.e. their basic chemical structure, thesecolorants exhibit widely varying thermalstability.

Color Stability Is Important

The very reactive carbonamide group inpolyamide favors physico-chemical pro-cesses that can lead to changes in the col-orant molecule (Fig. 1). With some col-orants, this is an irreversible process.This can be attributed to the formationof so-called electron donor-acceptorcomplexes. Under the action of atmos-pheric oxygen, the colorant reverts to itsoriginal structure and largely to its orig-

inal color. Some pigments of the peri-none type (Fig. 2a) exhibit this behavior,which is manifested in a brownish dis-coloration of the colorant during pro-cessing. In film extrusion, such colorchanges do not occur, because process-ing temperatures here are generallylower.

High-voltage plugs, for example, areoften colored in a characteristic red. Herethe use of colorants of the perylene typeleads to very good results (Fig. 2b). In theviolet range, pigments and dyes of the an-thraquinone family can be used (Fig. 2c).

Other important criteria in selectingsuitable colorants are the particle hard-ness and edge acuity of some inorganicpigments. Pigments of mineral origin of-

Multi-Touch_210x145mm_March 2013.indd 1 3/14/2013 3:58:31 PM

AF-ColorZweigniederlassung der Akro-PlasticGmbHD-56651 NiederzissenGermanyTEL +49 2636 8092-0> www.af-color.com

Contacti

16-19_PE111312_PE4 05.04.2013 13:44 Uhr Seite 17

18

SPEC I A L

© Carl Hanser Verlag, Munich Kunststoffe international 4/2013

ten have a marked abrasive tendency,which damages the glass fibers in rein-forced polyamides, causing drastic loss ofmechanical properties. This is a particu-lar problem with near-white colorants butalso with many colored ones. These addi-tional limitations compel colorists to turnto the previously described alternatives inthe range of synthetically produced col-orants.

To serve the market reliably therefore,further solutions are required that ensuresuitable processing stability in the uppertemperature range. But more far-reach-ing solutions have not so far been avail-able.

New Carrier System

As described above, it is possible to go acertain way towards meeting the highrequirements of polyamide colorationthrough the selection of suitable col-orants.

Another approach is to add a suitableantagonist that positively influences thevery reactive environment in the poly-amide melt. AF-Color, a subsidiary ofAkro-Plastic GmbH, Niederzissen, Ger-many, has developed a new carrier systemthat fulfills these conditions.

One specific challenge that coloristshad to address was the coloration of a

PA66 in a very brilliant orange shade.Since all colorants are only as stable astheir chemistry allows, in this particularcase a solution had to be found that guar-anteed the stability of the color system,even at temperatures of up to 320°C. Aconventional PA6-based formulation wascompared with a formulation based onthe new carrier system. In both cases, thesame colorants were used: a colorant witha perinone base structure (main compo-nent) and a colorant of the anthraquinonetype.

Polymer melt in the barrel of the injec-tion molding machine was exposed totemperatures of 300 and 320°C respec-tively for periods of 4 min. The testplaques molded from this material werecompared visually and colorimetrically

with injection molded plaques producedat 280°C, i.e. without additional temper-ature stress (Fig. 3, Title picture). The CIELabvalues in Table 1 show the different colorchanges as a function of the two carriersystems.

It then became interesting to find outwhether, on the basis of the new carrier,better thermal stability could be ob-tained with other colorants, e.g. those ofthe diketopyrrolopyrrole group (Fig. 2d).To this end, polymer melt containing acolorant of the aforesaid group was sim-

ilarly exposed to temperatures of 300and 320°C respectively for 4 min in thebarrel of the injection molding machine.The injection moldings were again com-pared with the test plaques molded at280 °C. Figure 4 shows the test plaquesmolded at 280°C (top row) and 300°C(lower row).

Conclusion

The color system based on the new carri-er showed very good stability results at320°C for 4 min as compared with a con-ventional PA6 carrier system (Fig. 5).

The carrier system described has al-ready proven successful in some specificinjection molding applications. Thispromising performance must be verifiedin further applications. The transfer ofthis concept to other color systems is thesubject of current development proj-ects.�

THE AUTHORS

DIRK SCHÖNING, born in 1970, is head of productmanagement at AF-Color, a subsidiary of Akro-PlasticGmbH, Niederzissen, Germany; [email protected]

DR. INNO GAUL, born in 1962, is R&D Director atAF-Color, a subsidiary of Akro-Plastic GmbH,Niederzissen; [email protected]

Temperature[°C]

CIELabPA6-

carrierAFC-

carrier

300 dL* -1.37 -1.73

da* 0.71 1.43

db* -2.68 -1.49

320 dL* -3.26 -3.77

da* -1.78 0.17

db* -6.47 -3.84

Table 1. CIELab values for PA6 and the new car-rier as a function of heat stress

Fig. 3. PA66 test spec-imen with conven-tional color systembased on a PA6 carri-er (left) and formula-tion with a newlydeveloped carriersystem (right)

Fig. 4. Test parts colored with a diketopyrrolopyrrole-based pigment (left:with PA6 carrier, right: with new carrier)

Fig. 5. Colored test plaques injection molded from polyamide 6 after thepolyamide melt has been exposed to a temperature of 320°C for 4 min (left:PA6, right: with new carrier)

16-19_PE111312_PE4 05.04.2013 13:44 Uhr Seite 18