b CLLH gb - Carl Stahl · 2017. 2. 13. · Service Load cha Pulleys .. . Load hoo Gear ..... . Gear...

Transcript of b CLLH gb - Carl Stahl · 2017. 2. 13. · Service Load cha Pulleys .. . Load hoo Gear ..... . Gear...

-

2

Pos: 2 /1_HADEF/---ALLG

Th

Pos: 3 /2_CS/---ALLGEMo

To OrTraA cSu Pos: 4 /1_HADEF/---ALLG

Ta

1 2 2.12.22.32.42.5

3 3.13.23.3

4 4.14.24.34.4

5 5.1

6 7 7.17.27.3

8 8.18.2

9 10101010

GEMEIN/Allgemein/2.unvollständige Maschine/HINWEIS - unvollständige Masch. -Montageanleitung @ 1\mod_126044999

NOTIe installation

EIN/Allgemein/3.Copyright/Copyright f. BA's @ 3\mod_1366028624567_52.docx @ 26494 @ @ 1

by CarlStahobelstr. 2 * D

iginal operatanslation in ocopy may beubject to chan

GEMEIN/Allgemein/4.Inhaltsverzeichnis/Inhaltsverzeichnis Ü1-2 @ 0\mod_1171286846268_52.docx @ 56 @ @ 1

able of Co

InfoSafe

1 Warn2 Duty3 Requ4 Appr5 Basi

Tra1 Tran2 Safe3 Stora

Des1 Area2 Desi3 Func4 Impo

Tec1 Main

InstOpe

1 Devi2 Brak3 Tran

Com1 Gene2 Load

Safe0 Mai0.1 Gene0.2 Mon0.3 Repl

97342_52.docx @ 11373 @ @ 1

CE! n or mounting

hl GmbH D-73079 Sue

ting- and maother languae requested inges.

ontents

ormationety .........ning noticey of care ofuirements ropriate usic safety m

nsport ansport ........ety device fage ...........

scriptionas of applicign .............ctions ........ortant com

chnical dn dimensio

tallation .eration ...ices from 0ke and pawnsmission o

mmissioeral ...........d chain ......

ety checntenanceral ...........itoring ......lacing the l

g instructions

essen (Germ

intenance inges is made n writing from

...........................e and symbf the ownerfor the ope

se ..............measures ...

and Stora..................for transpo..................

.............cation ...........................................ponents ...

ata ........ns .............

..............

..............0,8 t up to 6

wl ...............of loads ....

ning ..........................................

ck ...........ce ...............................................load chain

s for incompl

many) * www

structions inof the Germ

m CarlStahl.

..............

..............bols ...........r .................erating per....................................

age ..........................

ort ................................

..............

..................

..................

..................

..................

..............

..................

..............

..............6,3 t ...............................................

..............

..................

..................

..............

..............

..................

...................................

lete machine

w.carlstahl.c

German lanman original.

..............

..............

..................

..................rsonnel ..........................................

..............

..................

..................

..................

..............

..................

..................

..................

..................

..............

..................

..............

..............

..................

..................

..................

..............

..................

..................

..............

..............

..................

..................

..................

es you’ll find

om

nguage.

...............

.........................................................................................................

.....................................................................

.......................................................................................

.................................

...............

.....................................................................

...................................................

...............

.....................................................................

C

in chapter “I

...............

.........................................................................................................

.....................................................................

.......................................................................................

.................................

...............

.....................................................................

...................................................

...............

.....................................................................

CS.5.52.187

nstallation”

..............

..............

..................

..................

..................

..................

..................

..............

..................

..................

..................

..............

..................

..................

..................

..................

..............

..................

..............

..............

..................

..................

..................

..............

..................

..................

..............

..............

..................

..................

..................

.00.01.02

........ 3

........ 4

........... 4

........... 4

........... 5

........... 5

........... 5

........ 7

........... 7

........... 7

........... 7

........ 7

........... 7

........... 7

........... 7

........... 8

........ 8

........... 8

........ 8

........ 9

........... 9

......... 10

......... 10

...... 10

......... 10

......... 11

...... 11

...... 11

......... 11

......... 11

......... 11

-

CS.5.52

11 11.1 11.2 11.3 11.4 11.5 11.6

12 12.1 12.2 12.3 12.4 12.5 12.6 12.7

13 14 15 15.1 15.2

16 17 Pos: 5.1 /1_HADEF/1--INFORMATION/*Ü1*/#.Kapitel - Information @ 0\mod_1174

1 Pos: 5.2.1 /1_HADEF/1--INFORMATION/Allgemein/*Information*/01.Information @

The prodThe entiThe prodAfter assFor the oThe statein this mBefore dduring trThis maunderstaPos: 5.2.2 /1_HADEF/---ALLGEMEIN/Hinweise/Prüfungen/HINWEIS - Vorgeschrie

NWe referregular pIn other Pos: 6.1 /1_HADEF/2--SICHERHEIT/*Ü1*/#. Kapitel - Sicherheit @ 0\mod_1172054

.187.00.01.0

InspectPeriodic cCheckingCheckingCheckingCheckingChecking

ServiceLoad chaPulleys ...Load hooGear .......Gear spriLubricantLubricant

TroubleRemedyDecommTemporarFinal dec

DocumSpare P

4470941082_52.docx @ 811 @ @ 1

Informa@ 0\mod_1176734820982_52.docx @ 4653 @ @ 1

ducts meet Ere company duction of cosembly, eachoperation of ed performa

manual. delivery, all ransport. Repanual allows anding and c

ebene Prüfungen @ 0\mod_1174472067892_52.docx @ 821 @ @ 1

NOTICE! r to the prescperiodic inspcountries an

54959462_52.docx @ 172 @ @ 1

02

tion .......checks .....

g the load cg the load hg – pawl ....g – Brake Sg – Suspen

e .............ain ...............................ok ................................ng pressut - Selectiot for food i

e ............y ...........missioniry decommommission

ents avaParts Lis

tion European Unworks acc. t

omponents ath product is shoists, the nnce of the de

products areport any dam

a safe andcan be differe

cribed equipections.

ny additional

..............

..................chain .........hook ............................

System ......sion and lo

..............

..................

..................

..................

..................re brake ...n ...............ndustry – S

..............

..............ing ........

missioningning/dispos

ailable ont ............

nion requiremo a certified t our work is subject to a fational accidevices and m

e packed promage immedid efficiently ent from the r

ment tests b

national regu

..............

..................

..................

..................

..................

..................oad hook b

..............

..................

..................

..................

..................

..................

..................Selection (

..............

..............

..............

..................sal .............

n reques..............

ments, in partquality assusubject to st

final test withdent preventimeeting any w

operly. Checiately to the fuse of equireal design.

before initial s

ulations mus

.........................................................................................................

bolt ............

...........................................................................................................................as option*)

...............

...............

...................................................

st ...........................

ticular the varance systemtrict, intermeh overload. on regulationwarranty cla

ck the goodsforwarding apment. Imag

start-up, befo

st be observe

...........................................................................................................................

...........................................................................................................................) .................

...............

...............

...................................................

...............

...............

alided EU Mam as per ISOdiate checks

ns apply in Gims require a

s after receigent. ges of this

ore putting b

ed.

..............

..................

..................

..................

..................

..................

..................

..............

..................

..................

..................

..................

..................

..................

..................

..............

..............

..............

..................

..................

..............

..............

achine DirectO 9001. s.

Germany, amadherence to

ipt for any d

manual are

ack into ope

.............

..................

..................

..................

..................

..................

..................

.............

..................

..................

..................

..................

..................

..................

..................

.............

.............

.............

..................

..................

.............

.............

tive.

mongst otherso all instructio

damage caus

for a princ

eration and th

3

12 . 12 . 12 . 13 . 13 . 13 . 13

14 . 14 . 14 . 14 . 15 . 15 . 15 . 15

15 16 17 . 17 . 17

17 18

s. ons

sed

iple

he

-

4

2

2.1Wa

Pos: 6.2.2.1 /1_HADEF/2

2.2ThthatecOusuattregexHotakthaConowoIn

Pos: 6.2.2.2 /1_HADEF/--

It is Pos: 6.2.3 /1_HADEF/2--S

Safe

1 Warnarnings and

DANG

WARN

CAUT

NOTI

--SICHERHEIT/Allgemein/Sorgfaltspflicht des Betreibers/04.Sorgfaltspflicht des Betreibers @ 0\mod_1172050137593_52.

2 Dutye unit was d

at are to be cchnology andur delivery inpplied with caching devicgulations. Foplosion, or th

owever, in evken. It falls wat they are beomplete the tifications)tha

ork, work flowparticular, thThe unit is oThe deviceparticular, aThe requireand is usedThe operatiare legible aThe unit is oThis personprotection, acontains. Any safety aDevices forresistor of <

--ALLGEMEIN/Hinweise/WARNUNG - Keine konstuktiven Änderungen @ 0\mod_1176797173443_52.docx @ 4704 @ @

WARNs not allowed

SICHERHEIT/Allgemein/Anforderungen an das Bedienpersonal/05.Anforderungen an das Bedienpersonal @ 0\mod_1172

ety

ning noticenotice are sh

GER! T

NING! T

TION! Ts

CE! G

D

D.docx @ 162 @ @ 1

y of care ofdesigned andcomplied witd provides thncludes the control, the ces as well aor explosionhey must be veryday ope

within the dueing complie

operating at are impor

w and humanhe owner/useonly used ap

e is only opeare checked ed personal . ng instructioand completeonly operatednnel is regulaand that they

and warning r use in are< 106 Ω again

@ 1

NING! d to make co

2055544978_52.docx @ 179 @ @ 1

e and symbhown as follo

This means tha

This means tha

This means that thsurrounding.

Gives advice fo

Danger from ele

Danger from ex

f the ownerd built followth, as well ashe highest de

hoist suppliecontrol line/

as main ene-proof equipsuitable for u

eration this dty of care of

ed with. and install

rtant for the n resources. er must ensuppropriately. erated in a regularly to eprotective eq

ons are alwaye. d, serviced aarly trained y are familiar

signs on theea prone to nst earth.

onstructive ch

bols ows in these

t there is a high

t there is a risk

here is little risk t

r use and other

ectricity.

xplosive area.

r ing a risk ans other technegree of safeed beginning/hose that lergy supply li

pment, all thuse in area pdegree of saf the owner/u

ation instruspecial kind

re that:

fault-free, fuensure that itquipment for

ys available

and repaired in all applicar with the op

e devices areexplosion m

hanges of th

instructions:

h risk that leads

k that could lead

that could lead, if

r useful informa

nalysis and cnical specificety. g at its susp

eads to the ines must behese parts mprone to explafety can onuser of the d

ctions by ad of use of t

ully functionat is functioninr the operato

at the locatio

by qualified able matters

perating man

e not removemust (from c

e equipment

:

s, if it is not avo

d, if it is not avo

it is not avoided,

ation.

careful seleccations. It the

pension andhoist. Furthee assembledmust be applosion. The only be achievdevices to pl

any instructthe equipme

al condition,ng properly.ors, service

on where the

and authorizs regarding sual and, in p

ed and remaicustomer's s

t!

C

ided, to death o

ided, to death o

to slight injury or

tion of the herefore repre

d ending at ter operating d according tproved for uowner is respved if all mean these me

tions (regarent, i.e. rega

and the sa

and repair p

e equipment

zed personnesafety at worparticular, the

n legible. ide) be eart

CS.5.52.187

or severe injury

or severe injury

r damage to the d

harmonized sesents state-

the load hoomaterial, to

to the valid ruse in area ponsible for teasures reqeasures and

rding supervarding organ

afety compo

personnel is

is used and

el. rk and envire safety instr

thed with a

.00.01.02

y.

y.

device or its

standards of-the-art

ok and if ools, load rules and prone to

this. uired are to check

vision or ization of

onents, in

available

that they

onmental ructions it

shunting

-

CS.5.52

2.3 The unit. They mBefore sespecialThis is emaintena

DAIn order Use p Do no Do no Do noPos: 6.3 /1_HADEF/2--SICHERHEIT/Bestimmungsgemäße Verwendung/01.Alle (a

2.4 The permload test

The pat all

Defecorigin

LiabilPos: 6.4 /1_HADEF/2--SICHERHEIT/Bestimmungsgemäße Verwendung/05.Alle Ra

Vertic The h

DARatchet Only in t

The Ratccorrespo

NIf the unThe owninappropPos: 6.6 /1_HADEF/---ALLGEMEIN/Hinweise/GEFAHR - Losreißen, Personentr., s

DAIt is not a Pullin The u To tra The d Perso Moto Block Charg Dragg

2.5 Obse

.187.00.01.0

Requiremits may only must have thstarting workly the chapteespecially imance work.

ANGER! to avoid sevprotective cloot wear long ot wear ringsot wear cloth

außer 380) @ 2\mod_1300955165911_52.docx @ 18464 @ @ 1

Appropriamitted safe wt, carried outpermissible apower drivective devicesnal spare parlity and warraRatschzüge @ 2\mod_1300955975703_52.docx @ 18480 @ @ 1

cal lifting andhoist must be

ANGER!Lever Hoists

this case it is

chet Lever Honding EU-D

NOTICE! its are not usner and opepriate use.

schweb.Lasten, ex verboten (H) @ 0\mod_1176815143933_52.docx @ 4805 @ @ 1

ANGER!allowed: ng loose of stuse in area aansport peopdevice is not ons must notr drive of theking of the loging the loosging of loads

Basic saferve installati

02

ments for thbe operated

heir employek, the operaer "Safety Insmportant for

vere injury, plothes/equipmhair hanging

s or other jewhes that are t

ate use working load t by a licenseambient temn devices -2s and load srts must be uanty will becod lowering ase able to pos

! s with ship hos permitted th

Hoist is “a hoeclaration of

sed approprierator have s

!

tuck loads, dat risk from eple with the esuitable for

t stand undee equipment.ose chain en

se chain end.s with motor-

fety measuon-, operatio

he operatind by qualifiedr’s authorisating personnstructions". operating pe

lease pay attment. g down openwellery. too big/wide.

of the deviceed qualified pperature dur0 ° C / + 40 °suspension dused. Non-coome void if us well as pullsition itself ac

ook may onlyhat the hook

ist ready for f Conformity.

ately, it is nosole liability

dragging of loxplosion.

equipment. use on stager a suspende nd. . -driven hoists

res on and maint

ng personnd persons thaation for opernel must hav

ersonnel tha

tention to the

n.

es must not person. ring operatio° C! devices musompliance wiunauthorizeding and tightcc. to the loa

y be used fois charged a

operation” a.

ot possible tofor all pers

oads and inc

es and in stued load.

s.

tenance instr

nel at are appropration of the uve read the

at rarely use

e following w

be exceeded

n of manual

st not be usell result in an

d modificationtening of load

ad

r tightening!at its point!

cc. to the va

o ensure safesonal injury a

clined pulling

udios!

ruction.

priately traineunits. operating a

s the equipm

when using th

d! An except

driven devic

ed until theyny warranty cns of the unitds.

lidated, natio

e operation. and damage

is not allowe

ed and that a

and installati

ment, i.e. fo

he equipmen

tion can be m

ces is -20 ° C

y have beenclaims becomts are made

onal regulatio

e to property

ed.

are familiar w

on instructio

or installation

t:

made during

C / + 50 ° C a

n repaired! Oming void. by the user!

ons with the

y arising fro

5

with

ons,

n or

the

and

Only

m

-

6

Th Pos: 7.1 /1_HADEF/3--TR

Take noticeObserve saTake care foOnly use thThe equipmmoved. Never load Pay attentioShould the Supporting adequate saa structural If the equipsuch as chputting the eDo not use Stop workinAny damagIf the unit isPlease pay methods of The lifting thook. The safety cWhen chargStop lowerilowered furtThe load chTwisted chaThe correct The chain liWhen chargWe recommMotor drive

WARNe following isto lift anotheto manipulaThe use of eNever loop Never repaiDo not operNever use aIt is prohibitIt is prohibitIt is prohibitIt is prohibitDo not use Do not use Do not leav

RANSPORT/LAGERUNG/*Ü1*/#. Kapitel - Transport und Lagerung @ 0\mod_1172058584305_52.docx @ 190 @ @ 1

e of caution nafety distanceor a free viewe hoists app

ment is to be

the devices on to the acchoist be usestructures aafety factor tengineer. ment has noains, load hequipment ba hoist that i

ng immediatee and faults

s put into motattention to attaching loa

tackle or the

catch of hooged, the housng the load ther. hain must notains must be

alignment onks must alwged, the hous

mend a unit wis prohibited

NING! s not alloweder load than ate the slidingelongated orthe load chair damaged lrate the hoistan elongationted to chargeted to weld oted to swing ted to use thethe hoist whthe lever wite a lifted loa

notes at unitses. w on the loadropriately. used exclus

beyond theirident prevend outside of nd load-attacto handle the

ot been usedooks etc. anack into opes defective,

ely in case ofmust be reption, any per the regulatiads. load must b

ks must be csing may notwhen the bo

t be twisted. aligned befo

of the chain liways be alignsing may not

with sliding cld.

d: the nominal g clutch r damaged cain around a oad hooks (et by steppingn piece for the the load hoor cut when athe load. e load chain en it makes thout rubber d unintended

s and in the m

d.

ively for mov

r working loantion regulatioGermany, plched devicese rated load p

d for a periodnd replace aration! pay attentionf disturbanceorted to a res

rsons in the ions for load

be securely a

closed. t be in contaottom block o

ore attachingnks can be sned in one dt be in contalutch to preve

safe working

hains. Replaload nor place.g. by hammg on the levehe lever. ook at its poina load is susp

for earthing abnormal nohandle. d for a longe

manual

vement of go

ad limit. ons (UVV). lease pay atts used in conplus the weig

d of time, caany damaged

n to any abnoes and remedsponsible summediate vi

d carrying de

attached to

act somewheor the load i

g the load. seen from thirection.

act somewheent overload

g load

ace worn out ce or pull themering). Theer with a foot.

nt. (Only allopended.

during weldioise.

er period of ti

oods. Under

tention to thenjunction witght of the equ

arry out visuad parts with

ormal noise dy failures. upervisor immcinity must b

evices UVV f

the hook an

re. is being set

e weld seam

re. d, when the u

chains immee chain over y must be re.

wed for hois

ing.

me.

C

no circumsta

e national regh this equipmuipment. In c

al checks of new, origina

it makes dur

mediately. be informed bfor both posi

d be seated

down or is p

ms.

Illustr

unit is used fo

ediately by nedges.

eplaced by or

ts with shipy

CS.5.52.187

ances my pe

gulations thament must pcase of doub

all main comal spare par

ring operatio

by calling to itive and non

d at the botto

prevented fro

ration 1

or tightening

new, original

riginal hooks

yard hook)

.00.01.02

ersons be

at apply. rovide an

bt, consult

mponents rts before

n.

them! n-positive

om of the

om being

,

chains.

s.

-

CS.5.52

3 Pos: 7.2 /1_HADEF/---ALLGEMEIN/Hinweise/VORSICHT - Transport, Lagerung: ni

CTransporor improp

3.1 The dev Do no Use aTranspo

3.2

NShould a

3.3 Store Prote Prote

4

4.1 The devIf they asunshinecontinuoendangeAmbientnot unde

It

4.2

CARL SThoists w

4.3 The loadlowering

NIf used "slipping

.187.00.01.0

Transpoicht sachgemäß - keine Haftung @ 0\mod_1176819827794_52.docx @ 4910 @ @ 1

CAUTIONrt may only beper storage.

Transporvices are cheot throw or dadequate mert and mean

Safety de

NOTICE!a safety devi

Storage e the equipmect the equipect hooks, wi

Descrip

Areas of aices must bere used in the, dust, etc.ously humidered by the fot temperatureer water

DANGt is not perm

Design

TAHL ratcheith suspensio

Functionsd is lifted, lowg of the load.

NOTICE! "overhead" oclutch for the

02

ort and St

N! e done by qu

rt ecked and if rop the equi

eans of transs of transpor

evice for tra

! ce for transp

ent at a cleament againsre ropes, cha

tion

applicatione as far as pohe open, pro. - we recom environmeorming of coe -20°C up to

GER! itted to use t

et lever hoistson hook for s

s wered or ten

or "lashing" uese cases.

torage

ualified person

so adequatepment.

sport. rt must be su

ansport

port exist, ple

an and dry plat dirt, humidiains and bra

n ossible instalotect the unitmmend to u

ent with strndensation.o +50°C. Pow

he unit in an

s are compastationary us

nsioned by o

undefined for

nnel. No liabi

ely packed be

uitable for the

ease remove

ace. ity and dama

akes against

lled in a covets against thuse a coverrong temper

wer-operated

n area at risk

act se.

operating the

rces may ap

ility for any da

efore delivery

e local condi

it before com

age by an apcorrosion.

ered room. e effects of

r in parking rature fluctu

d units -20 u

from explos

Illustration

lever. The l

pear. We rec

amage result

y.

tions.

mmissioning

propriate cov

weather sucposition. If

uations, the

up to +40°C.

ion!

2

oad pressur

commend to

ting from imp

g.

ver.

ch as rain, hathe device

e correct fu

Humidity 10

re brake prev

o use a hoist

roper transpo

ail, snow, diris set up in

unctionings

00 % or less

vents autom

with

7

ort

rect n a are

but

atic

-

8

os: 8.3.2.2 /1_HADEF/---A

Ththe

4.4 Ge Ho

A nhaforAc(liftno

Ma Acon Fo

Fo

5 CaTywiNuLolowlevwewe

5.1

Ca

Pro

(All dPos: 10.1 /1_HADEF/6--M

6 Pos: 10.2 /1_HADEF/6--M

Ple

Pos: 11.1 /1_HADEF/7--B

ALLGEMEIN/Hinweise/HINWEIS - Schutz vor Funktionsstörung H @ 0\mod_1176993694604_52.docx @ 5003 @ @ 1

NOTICe best protec

e equipment.

4 ImpoGear

ear componeLoad pressu

olds the load

new brake syve sintered b

r lifetime of thccording to Dting/loweringminal load.

Housing ade from stee

Load chain ccording to Ely use originaLoad hook

orged steel. RFree-wheeli

or pulling thro

Tecapacity ype ith shipyard hook as oumber of chain falls oad chain dimensionsw headroom dimensiover force approx. eight* approx. eight per add. m lift ap

1 Main

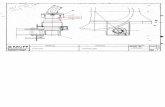

apacity t 0,8

oduktnr. CLLH008 A 119 B 144 C 35,5 D 245 E 97 F 14 G 26,5 H 280

dimensions in mm) MONTAGE/*Ü1*/#. Kapitel - Montage @ 0\mod_1172127582099_52.docx @ 255 @ @ 1

InstMONTAGE/Ratschzug/01.Allgemein @ 0\mod_1176303171712_52.docx @ 3778 @ @ 1

ease observePlease readBefore loadclosed. Make sure t

BEDIENUNG/*Ü1*/#. Kapitel - Bedienung @ 0\mod_1172647408811_52.docx @ 398 @ @ 1

CE! ction against.

ortant com

ents are madure brake in any positi

ystem is usebrake liningshe hoists and

DIN 13157 lifeg movements

el plate.

EN 818-7-T hal chains.

Rotating, thising of chain

ough of the u

hnical da

opion

s mon m

kpprox. k

n dimensio

1 1,6

CLLH010 CLLH01119 126 144 159 42,5 42,5 245 265 97 100 15 19 29 32

300 335

tallation e the followind chapter "Sading the hois

that the faste

t functional f

ponents

e of high-qua

ion.

d for the hois which maked appropriateetime is 1500s) with 300 m

igh quality c

s facilitates a

uncharged ch

ata t 0,8 CLLH008 - 1

mm 5,6x15,8 mm 280 N 290 kg 5,7 kg 0,7

ns

2,5 3

16 CLLH025 CLL150 1173 147 5

265 4102 121 24

36,5 3375 3

ng points in oafety". st make sure

ening positio

ailures in cas

ality material

sts. Brake dies them weare use. 0 operating cmm lift with

hain. All com

ttaching the

hain.

1 1,6 CLLH010 CLLH01

- S 1 1

5,6x15,8 7,1x20300 335 360 340 5,9 8,0 0,7 1,1

3,2 6,3

H032 CLLH063 59 217 90 190 50 60 15 415 12 112 4,5 34 39 50 95 540

order to avoid

e the hooks

n cannot be

se of extrem

l.

iscs r-free

cycles

mponents ma

load and avo

2,5 16 CLLH025 C

- 1

,1 9,0x24,8 1375 370 11,2 1,7

Illus

d any damag

are placed s

changed eith

me environme

Illustration 3

atch precisely

oids twisting

3,2 6,3 LLH032 CLLH063

S - 1 2

0x28,1 10x28,1 395 540 370 380 15,0 26,0 2,3 4,7

stration 4

ge to equipm

safely. The s

her by the lo

C

ental impact i

y to each oth

of the chain

ment or injury

safety catch

ad nor by oth

CS.5.52.187

is the regula

her. Therefo

. With safety

y of person:

of the hook

her influence

.00.01.02

r use of

re please

y catch.

k must be

es.

-

CS.5.52

7 Pos: 11.2 /1_HADEF/7--BEDIENUNG/Allgemein/01.Bedienung - Alle @ 0\mod_117

Only peooperatioensure toperatingPos: 11.3.1 /2_CS/7--BEDIENUNG/Ratschzug/04.Bedienung - CCLH ( 53/07) @ 3\

7.1 Before sForcible pin in poLifting oTurn thepulling aload by o

LowerinTurn therelievinghand levPos: 11.3.2 /1_HADEF/7--BEDIENUNG/Ratschzug/05.Kettenfreilauf 53/07 ab 800k

7.1.1 When thimpossib

DNever try

Switchin switc

Pull tdirect

The direct

Switchin

Turn directtime.

Free-OFF.

Free-

.187.00.01.0

Operatio73087534915_52.docx @ 440 @ @ 1

ople that aren. They musthat the operg personnel.\mod_1417101148029_52.docx @ 28290 @ @ 1

Devices fstart up pleas

pulling may osition "▼", dor pulling e switching as marked onoperating the

ng or relievine switching

g (2) and mover.

kg @ 0\mod_1176359658888_52.docx @ 3820 @ @ 1

Free-wheehe hoist is usble.

DANGERy to activate

ng ON the fr

h in middle p

he free-wheetion ▲ . chain can

tions.

ng OFF the

the free-whetion ◄ and p

-wheeling wh -wheeling me

02

on e familiar withst be authorizrating instruc.

from 0,8 t use make surepossibly clo

do some lowe

pin in posin the type ple hand lever.

ng pin in pos

ove the load

eling of chaised appropr

! the free-whe

ree-wheelin

position

eling wheel u

be pulled

free-wheelin

eeling wheel pull the load c

heel turns ba

echanism sw

h the operatized by the ections are av

up to 6,3 t e the free-whse the brakeering operati

tion (1) liftinate and mov.

sition lowerin by operatin

n iately, uninte

eeling mecha

g mechanis

upwards in

through in

ng mechani

with one hanchain at the

ack to positio

witched OFF

ion of the liftemployer for vailable near

heeling meche and stop thon movemen

ng or ve the

ng or ng the

Ill

ended activa

anism by forc

sm

both

ism

nd in same

on

ting devices the operatio

r the equipm

hanism is deae chain. Shonts and begi

ustration 5

ation of the f

ce if the hois

Illustration

Illustration

C

Illustration

and cranes n of the equent and that

activated. ould this be tn lifting again

free-wheeling

st is under ch

6

A free-whB free-whee

7

C free-wheelD free-wh

8

may be entripment. The

t they are ac

the case placn.

g mechanism

harge.

heeling is OFeling switched

ing switchedheeling is OF

rusted with themployer m

ccessible for

ce the switch

m under load

FF d ON

d OFF FF

9

heir must

the

hing

d is

-

10

7.2Th

ThRe

Pos: 11.3.4 /1_HADEF/7-

7.3Whlow

Pro

Pos: 12.1 /1_HADEF/9--I

8 Pos: 12.2.1.1 /1_HADEF/

8.1ShPleFoIns Pos: 12.2.1.2 /1_HADEF/

HopeHomoAncoDeA “doDeA “mateckinPos: 12.2.2.1 /1_HADEF/

2 Brake brake remThe ratcheta load is "traThe load hoe chain does

emedy: Charge the Release theOR: Turn th"▼".

-BEDIENUNG/Ratschzug/08.Übergabe von Lasten - Alle @ 2\mod_1292316859244_52.docx @ 17800 @ @ 1

3 Tranhen loads arwer as the br

oceed as foll

Lift the loadSuspend thand lift it uhook, but doEffect movehoist (B) takNow hoist open again.

NBETRIEBNAHME/*Ü1*/#. Kapitel - Inbetriebnahme @ 0\mod_1177486166685_52.docx @ 5393 @ @ 1

Com9--INBETRIEBNAHME/Allgemein/Allgemein/01.Allgemein @ 0\mod_1172504961658_52.docx @ 355 @ @ 1

1 Genehould the unitease observeor other counspections as

---ALLGEMEIN/Hinweise/Prüfungen/HINWEIS - Prüfung durch befähigte Pesonen @ 0\mod_1177339966681_52.docx @

NOTIoists up to 10rson” before

oists of 1000 ovement, mun exception nformity.

efinition “qu“qualified perne, the skills

efinition “lic“licensed quaaterial for onchnical regulnd of use. Th

9--INBETRIEBNAHME/Allgemein/Lastkette/06.Lastkette @ 0\mod_1178195068515_52.docx @ 5681 @ @ 1

ke and pawains closed (t lever hoist iansmitted" toook is pulled s not move, t

ratchet levee brake by sehe switching

nsmission ore transmitterake is closed

lows in such

d with the hoihe load fromntil the loado not uncharement lowerkes over the (A) is uncha.

mmission

eral t be used in e the validatetries: above. Plea

@ 5319 @ @ 1

ICE! 000 kg capac putting into kg capacity

ust be tested is “hoists re

ualified persrson” has lea

s needed to tensed qualialified persoe’s work andations. This e license wil

wl (stuck) if: s uncharged

o another hoagainst the hthe load can

r hoist againetting down tpin to positio

of loads ed from one d at the time

cases:

st (A). m the hook o

hangs securge the hoist ring with hocomplete ch

arged and th

ning

Germany: ed, national a

ase observe t

city and withooperation foand up or wby a “license

eady for op

on” (formerarned, due totests the matified person

on” has, due d knows theperson mus

ll be given to

d without lowist or in casehousing and not be lower

the load on "Lowering

hoist to ano of transmiss

of hoist (B) urely in the (A). ist (A) until

harge/load. he brake is

accident pre

the national r

out motor-drr the first tim

with more thaed qualified p

peration” acc

r expert) o occupationterial for one

n” (former apthrough spe national acc

st test the mao qualified pe

wering the loae of horizonta got stuck thred.

g" and releas

other, the hosion.

Illustr

vention regu

rules and reg

riven trolleys me. an one motorperson” befoc. validated

al training an’s work. pproved exp

ecial occupatcident preveaterial for on

erson be the

ad, i.e. in casal pulling/tenere

se the hand le

ist that gets

ration 9

ulations.

gulations and

of hoisting u

r-driven hoisore putting in

national reg

nd experienc

pert) tional trainingention regulane’s work regapproved su

C

se of verticalsioning.

ever with a s

the load is

d the instruct

unit must be

t movement;operation.

gulations wit

ce and the jo

g, knowledgetions and othgularly with

upervision au

CS.5.52.187

l lifting/lower

strong jerk in

not possible

tions in this m

tested by a

; i.e. lifting a

th EU-decla

ob that the pe

e about testiher prescriptregard to de

uthorities (ZÜ

.00.01.02

ring when

direction

e to lift or

manual!

“qualified

nd trolley

aration of

erson has

ng of the tions and

esign and ÜS).

-

CS.5.52

8.2 Befor MovePos: 12.2.2.2 /1_HADEF/---ALLGEMEIN/Hinweise/Ketten/VORSICHT - Ketten: Ke

CDo not uWithout Pos: 12.2.2.3 /1_HADEF/---ALLGEMEIN/Hinweise/Ketten/HINWEIS - Kettenlebens

NContinuo Pos: 13.1 /1_HADEF/10-SICHERHEITSPRÜFUNG/*Ü1*/#. Kapitel - Sicherheitsprü

9 Pos: 13.2 /1_HADEF/10-SICHERHEITSPRÜFUNG/Allgemein/01.Sicherheitsprüfun

Before p All faPos: 13.3 /1_HADEF/10-SICHERHEITSPRÜFUNG/Allgemein/Sicherheitsprüfung K

The c Pos: 14.1 /1_HADEF/12-INSTANDSETZUNG/*Ü1*/#. Kapitel - Instandhaltung @ 0\

10 Pos: 14.2.1 /1_HADEF/12-INSTANDSETZUNG/Allgemein/01.Allgemein @ 0\mod_

10.1 All monithey mus O Se Re

Pos: 14.2.2 /1_HADEF/12-INSTANDSETZUNG/Allgemein/02.Überwachung @ 0\m

10.2 The monoperatioenvironm Pos: 14.3.1 /1_HADEF/12-INSTANDSETZUNG/Lastkette wechseln/03.Alle @ 0\mo

10.3

CIf there dimensioWhen reProcedu Only

twiste Remo

A chaprodumust

Hang Make Make AssePos: 15.1 /1_HADEF/13-PRÜFUNG/*Ü1*/#. Kapitel - Prüfung @ 0\mod_117326408

.187.00.01.0

Load chare commissioe safety note

ein Fett, ohne Schmierung keine Haftung @ 0\mod_1177481784104_52.docx @ 5349 @ @ 1

CAUTIONuse grease folubrication, m

sdauererhöhung durch Schmierung @ 0\mod_1177481941192_52.docx @ 5355 @ @ 1

NOTICE! ous, thoroug

üfung @ 0\mod_1172647514342_52.docx @ 401 @ @ 1

Safety cng Alle @ 0\mod_1178197796463_52.docx @ 5700 @ @ 1

putting into sestening screKetten @ 0\mod_1172661092232_52.docx @ 429 @ @ 1

chains are co\mod_1172647603139_52.docx @ 405 @ @ 1

Mainten_1173251926256_52.docx @ 469 @ @ 1

General toring, servist be effectenly “qualifiedervicing and ecords must mod_1173254503420_52.docx @ 472 @ @ 1

Monitorinnitoring and sn. In case

mental conditod_1173275448587_52.docx @ 533 @ @ 1

Replacing

CAUTIONis any visiblons in the tabeplacing the cure:

insert new ced. ove chain fro

ain link whichuced by grindhave the sa

g a new origine sure the che sure the chmble the cha87196_52.docx @ 507 @ @ 1

02

ain oning the loa and fixing w

N! or lubricationmanufacture

h lubrication

check ervice initiallyws (if existenorrectly place

nance

cing and mad with utmos

d persons” mmaintenancebe kept of a

ng servicing inteof severe

tions (e.g., h

g the load c

N! e damage able have beechain, also c

chains in an

om its fasten

h is open at tding out a smme thicknes

nal chain (saain is not insain links areain to the end

ad chain muswire away fro

of load chair's warranty a

will increase

y or when punt), socket pied, oiled and

aintenance ost care.

may do this we work must

all test results

ervals statedoperating ceat, dust, etc

chain

and when then reached, tcheck the cha

unloaded st

ing at the en

the side, canmall piece. Ths as the cha

ame size andstalled twiste aligned in od fastening.

st be aligned m the chain.

in. and/or liabilit

e the life of th

utting back inins, flap sock

d in good con

operations a

work. only be don

s and measu

d are valid foconditions (ec.), the interv

e conditionsthere is corroain wheels.

tate and as t

nd and attach

n easily be he opening in link.

d oiled) in theed. one direction.

and oiled.

ty will be void

he chain con

nto service, itket and safetndition.

are to ensure

e when the hures taken.

or operation ue.g. frequenvals must be

s for replaceosion or elon

the chains th

h a chain link

Illustrae side opene

.

d.

nsiderably.

t must be chety devices ar

e correct fun

hoist is not lo

under normat operation shortened c

ment are regation), the c

hat are curre

k which is ope

ation 10 d chain link a

ecked whethre tightened

nctioning of

oaded.

al conditions with full lo

correspondin

eached (i.e. ochain must b

ently in the d

en at the sid

and insert it.

her: and secured

the equipme

and single-soad) or spengly

one or sevebe replaced.

device – i.e.

e.

11

d.

ent;

shift cial

eral

not

-

12

11 Pos: 15.2 /1_HADEF/13-P

11Indby Pos: 15.3.1.1 /1_HADEF/

11Th

Pos: 15.3.1.2 /1_HADEF/

Wh

Pos: 15.3.2.1 /1_HADEF/

CheCheChefor chaBraCheCleCheCheLoaCheCheHav(pe

Pos: 15.3.2.2 /1_HADEF/

If ocoPos: 15.3.3.1 /1_HADEF/

11acc

L1

L1

dm Pos: 15.3.3.2 /2_CS/13-P

Ch

Dim

Pos: 15.3.3.3 /1_HADEF/

Whrep

1 InspPRÜFUNG/Wiederkehrende Prüfung/01.Wiederkehrende Prüfung @ 0\mod_1175675257580_52.docx @ 3164 @ @ 1

.1 Periodependently a qualified p

13-PRÜFUNG/Kettenzug/Allgemein/01.Zu prüfende Teile @ 0\mod_1173259827552_52.docx @ 481 @ @ 1

.1.1 Come following m Dimensio The dime A visual

---ALLGEMEIN/Hinweise/Prüfungen/VORSICHT - Verschleißgrenzen @ 1\mod_1260457845218_52.docx @ 11380 @ @

CAUThen the wear

13-PRÜFUNG/Kettenzug/Tabelle-Inspektionsintervalle/02.Alle H + Ratschzüge @ 0\mod_1178696489864_52.docx @ 574

eck screw connectioneck lifting, lowering fueck brake function ratchet lever hoists: C

ain ake - check wear of breck chain wheels, ratc

ean and lubricate the leck the load chain foreck the load hook for ad hook - check the saeck and lubricate the eck the chain pulleys ve the equipment che

eriodic inspection) ---ALLGEMEIN/Hinweise/Kettenzüge/WARNUNG - Inspektion: Über,-unterschreiten Maße-Ketten,Haken @ 0\mod_11775

WARNone or severrosion are fo13-PRÜFUNG/Kettenzug/Lastkette/Lastkette - Maßerklärung @ 0\mod_1173261324103_52.docx @ 492 @ @ 1

.2 Checc. DIN 685-p

1 = pitch inc

= pitch incre

m = detected PRÜFUNG/Ratschzug/Lastkette/Tabelle - Ketten - 5,6x15,8 - 7,1x20,1 - 9x24,8 - 10x28,1 @ 3\mod_1417159563343_52.do

hain dimensio

mensions Mm 5,6x1L11 179L1 16Dm 5,

---ALLGEMEIN/Hinweise/Ketten/WARNUNG - Ketten: Bei Erreichen der Tabellenmaße durch Verschleiß oder Verformung

WARNhen the dimplaced!

pection

odic checkfrom the reg

person or lice

ponents to must be checons of load censions musinspection fo

@ 1

TION! r limit is reac741 @ @ 1

ns unctions.

Check free-wheeling m

rake lining chet wheels and pawlload chain. r elongation and wear cracks and deformatiafety catch bearing of the chain p ecked by a qualified pe

504456674_52.docx @ 5496 @ @ 1

NING! eral of the dound, the pa

cking the lopart 5

rease over 1

ease over 1 c

link thicknesocx @ 28310 @ @ 1

ons

15,8 7,1x29,1 227,6,6 21,20 6,4

ng die Ke @ 0\mod_1178705158838_52.docx @ 5763 @ @ 1

NING! mensions liste

ks gulations of tensed qualifi

be checkedcked: chain, load hst be comparor deformatio

ched, the par

mechanism of the

ls.

on

pulleys.

erson

dimensions farts must be r

oad chain

1 chain links

chain link

ss

Chain size

0,1 9x24,8,9 281,22 26,1

4 8,1

ed in the ta

he individualed person re

ooks, pawls,red to the dimons, cracks a

rt must be ex

at commissioning

X X X

X

X

X

fall below oreplaced with

s

8 10x28,2 318,6 29,6

9,0

able are rea

l countries, legarding its f

, bolts, ratchmensions in tand corrosion

xchanged by

daily

checks

X X

X

X

or exceed thh original spa

,1 6

ched due to

ifting devicesfunctional sa

et wheels, brthe tables. n must be ca

a new, origi

1st mainteafter

3 mont

X

X X

e dimensionare parts.

Illustrat

o wear or d

C

s must be chfety.

rake linings.

arried out.

nal part.

enance r ths

InspMaint

ev3 m

ns in the tab

ion 11

eformation,

CS.5.52.187

hecked at lea

pection tenance very

months

Inspe

1

X

X

ble, or if cra

the chain m

.00.01.02

ast yearly

ection Mainte-nance every

2 months X

X X

X X

X

X

acks or

must be

-

CS.5.52

11.3 Load hoo X = meaY = meaH = thick

Pos: 15.3.4.2 /2_CS/13-PRÜFUNG/Ratschzug/Lasthaken/Tabelle - Hakenmaße - 5

DimensioDimensi-

onmm

X bzw. Y H

Pos: 15.3.4.3 /1_HADEF/---ALLGEMEIN/Hinweise/Haken/VORSICHT - Haken bei V

CWhen thbottom tPos: 15.3.5 /2_CS/13-PRÜFUNG/Ratschzug/Sperrklinke/Tabelle - 53/07 CLLH @ 3

11.4 Typ

CLLH

Pos: 15.3.6 /2_CS/13-PRÜFUNG/Ratschzug/Sperrrad+Bremsbelag/Tabelle 53/07 C

11.5 Ratchet

t

0,8 1

1,6 2,5 3,2 6,3

11.6 Type

CLLH

.187.00.01.0

Checkingok

asuring distanasured lengthkness of hoo

53/07 CLLH @ 3\mod_1417159639465_52.docx @ 28322 @ @ 1

ons for load

0,8/1 1

26,5/41,5 31,520 2

Verformung.... @ 0\mod_1177582461489_52.docx @ 5510 @ @ 1

CAUTIONhe dimensionhickness is f3\mod_1417159746563_52.docx @ 28340 @ @ 1

Checking A

T m0,8-1,6 2

2,5 293,2-6,3 3

CLLH @ 3\mod_1417159799139_52.docx @ 28346 @ @ 1

Checkingwheel with b

D Vmin mm mm 64 61 64 61 64 61 64 61 74 71 74 71

Checking t

0,8/1 1,6 2,5 3,2 6,3

02

g the load h

nce hook moh from hook nok saddle

and suspens

Capacity in

/1 1,6/1

5/49,4 35,5/52 22 26,5

N! n of hook opefallen short o

g – pawl A Vmin

mm mm 22 20,5 9,2 27,7 31 29,5

g – Brake Sbrake linings

tn tvmm m8 8 8 8 8 8

g – Suspen

dn mm 12 12 14 16 16

hook

outh width no. 6

sion hooks

n t / Chain falls

2,5/1 3

41/58,6 429

ening width isof by 5% due

System

vmin mm 6 6 6 6 6 6

sion and lo

Suspension bolt

3,200/1 6,3/2

43/61,9 53/84,331,2 45,5

s deformed m to wear, the

oad hook b

dvmin mm 11,1 11,4 13,3 15,2 15,2

Illustra

3

more than 10e hook must b

bolt

Loadn mm 7,5

10,2 11,5 13 13

ation 12 Please fill in before comm

Capacity X or Y

H

0% or when be replaced.

ad hook bolt dvmin mm 6,9 9,7 11

12,4 12,4

the measuremissioning:

t mm mm

the dimensio.

n

ed values

on of the hoo

13

ok

-

14

12 Pos: 16.2.1.1 /1_HADEF/

12WeTousa

Pos: 16.2.1.2 /1_HADEF/

DoWi

12

Pos: 16.2.2 /1_HADEF/14

12

Us

Lo

Us

Pu

Us

Lobe

2 Serv14-WARTUNG/Kettenzug/Lastkette/01.Lastkette - Schmierung @ 0\mod_1173362815667_52.docx @ 588 @ @ 1

2.1 Loadear at the lin

o ensure optiage. Lubricate thAlways lubrnot sufficienfilm within thIf the samemovement mThoroughly compared toWash dirty cIf there are graphite powWhen lubric

---ALLGEMEIN/Hinweise/Ketten/VORSICHT - Ketten: Kein Fett, ohne Schmierung keine Haftung @ 0\mod_11774817841

CAUTo not use grethout lubrica

2.2 Pulle

4-WARTUNG/Kettenzug/Lasthaken/02.Lasthaken - Schmierung @ 0\mod_1173364066362_52.docx @ 594 @ @ 1

2.3 LoadCheck bearClean and lSlight bearinWhen beari

se

ad chain

se

ulleys

se

ad hook aring

vice

d chain ks is mainly imal lubricat

he chain withricate the chant to lubricathe links. Thee lifting opermust be give

effected luo dry run witchain with peenvironmenwder. cating the ch

104_52.docx @ 5349 @ @ 1

TION! ease for lubrication, manufa

eys

d hook rings and pulubricate the ngs are mainngs resp. sli

due to insufftion of the lin

a lubricant tain when it ise the chain f

e adjacent linations are c

en special attbrication of th unlubricateetroleum or atal influence

ain’s conditio

cation of loadacturer's war

leys yearly bearings of

ntenance freght bearings

ficient maintenks, the cha

that creeps, es not under lfrom the out

nk points muscarried out cotention. the chain w

ed chain. a similar cleas that foster

on of wear sh

d chain. rranty and/or

hooks and pe

s are worn of

enance of theain must be

e.g. automotoad so that ttside, as thisst always beonstantly, th

will prolong

aner, under nr wear, such

hould be che

r liability will b

pulleys with g

f, change the

Recom

Gear oil for FUCHS RENor special chaiUse NO gre

Recom

FUCHS RENOLIT

Recom

FUCHS RENOLIT

e chain. lubricated a

tive gear oil.the oil can w

s will not ens lubricated to

he switching

the life of

no circumstaas sand, a d

ecked.

be void.

grease

e complete p

mendation

example: NOLIN PG 220

n lubricant ase!

mendation

T FEP2

mendation

T FEP2

C

t regular inte

wet the links asure the formo prevent excarea from a

the chain b

nces heat thdry lubricant

ulley

0,2

Acc. to d

Acc. to d

CS.5.52.187

ervals, depe

affected by wmation of a lucessive weaa lifting to a

by approx. 2

he chain. should be u

2 l

demand

demand

.00.01.02

ending on

wear. It is ubricating r. lowering

20 times,

used, e.g.

Interval

3 month

Interval

12 month

Interval

12 month

-

CS.5.52

12.4 Regular years. Wuse (e.g

12.5 During talready r

CAThe brakincreaseThe brakappropri

NOAccordinnominal Use by hmust be wear lim

12.6 FUCHS

Renolit FEP 2

Stabylan 5006

12.7

Gearing

Load chain

Load hook Pulleys

Gear rim Drive pinion

* must be mPos: 17.1 /1_HADEF/15-STÖRUNG/*Ü1*/#. Kapitel - Störung @ 0\mod_117264829

13 Pos: 17.2.1 /1_HADEF/15-STÖRUNG/Allgemein/01.Störung @ 0\mod_1173250229

Please p Troub Secu Put u Secu PleasNotes onFor the r Pos: 17.2.2 /1_HADEF/---ALLGEMEIN/Hinweise/VORSICHT - Störung beseitigen b

CTrouble brake pa

.187.00.01.0

Gear checks of lu

We recomme. dust, regula

Gear sprihe check, breached at o

AUTION!ke linings mues wear. ke lining for tate use - and

OTICE! ng to EN 131load and noheavy condit checked mo

mit is reached

LubricantSHELL

Alvania EP 2

--

LubricantSHEL

FM Greas

--

FM Greas

mentioned by order95608_52.docx @ 413 @ @ 1

Trouble 9044_52.docx @ 460 @ @ 1

pay attentionbles with there the unit ag

up a warning re the workinse read the cn the repair orepair of failu

bei Verschleißteilen @ 0\mod_1177594576085_52.docx @ 5572 @ @ 1

CAUTIONcaused by w

arts, etc., mu

02

ubrication arend to use aar lifting of th

ng pressurake lining w

one position o

! ust be free fr

the ratchet led must only b

157 lifetime rmal operatiotions can shore than 1x

d or wear of t

t - SelectioESSO M

Unirex EP 2 Mob

--

t for food iLL

se HD2

se HD2

r

to the follow equipment mgainst unintenote indicati

ng area of mchapter "Safeof faults are fures please c

N! wear or dam

ust be remed

re necessarylubricant of

he nominal lo

re brake wear is verifiof the lining,

rom fracture.

ever hoist is be replaced

is 1500 operon conditions

horten the pryearly. The he lining (on

n MOBIL TOTA

ilux EP 2 MULTIS

-- --

ndustry – SMOBIL

Mobilegrease FM 22

Lubricant FM 100

Mobilegrease FM 22

wing in case omust only beended operating that the uoving parts o

ety instructiofound in the fcontact our s

mage to partied by replac

y. The teeth f class EP2 oad,etc.), ple

ed. The bra- as this can

. Avoid oil, g

tested for thin case of ex

rating cycless. roduct lifetimratchet whe

ne one side)

AL CAST

S EP2 --

Optimol Visc

Selection (C

22 Optimol

22

of problems:e repaired bytion start. unit is not to of the unit. ns". following tab

service depar

ts such as wcing the parts

must be cleor similar prase shorten

ke linings mn be the case

rease, dirt an

he whole proxtraordinary w

s (lifting/lowe

me. In these cel with the bis clearly vis

TROL

-

coleb 1500 Klüber

as option*)ASTROL

--

l Viscoleb 1500

--

: y qualified pe

be used.

ble. rtment.

wire ropes, cs with origina

eaned and reoducts. In camaintenance

must be replae when wear

nd humidity o

oduct lifetimewear.

ering movem

cases, the thbrake lining mible.

KLÜBER

--

roil 4UH 1-1500

)

rsonnel.

chains, chainal spare parts

e-lubricated ase of sevee intervals.

aced when tof the lining

on the brake

e - under the

ments) with 3

hickness of tmust be rep

n wheels, axts.

after approxre conditions

he wear limis is irregular

e linings as th

precondition

00 mm lift w

the brake linlaced when

xes, bearing

15

x. 3 s of

it is r.

his

n of

with

ning the

s,

-

16

14

ChLiftLoProb

Load

It is d

Load

Hois

Hois

The

Hois

Load

Load

SwitcLoadfree-Pos: 19.1 /1_HADEF/17-A

4 Remheck the ratcting: Move thwering: Only

blem

d is not lifted

difficult to lift the load

d is lifted with interrup

t does not lift without

t does not lift the who

brake remains closed

t does not lower the lo

d slips down partially d

d slips down during low

ching pin does not fund slips down when the-wheeling mechanism

AUßERBETRIEBNAHME/*Ü1*/#. Kapitel - Außerbetriebnahme @ 0\mod_1172648336045_52.docx @ 417 @ @ 1

medy het lever hoihe lever forwy move the le

tions

load

ole distance long

d (stuck),

oad

during lowering

wering

nction e switching pin is switc

m.

st by listeninward and bacever backwar

Cause Overlo

Load g

Brake

Load c

Defect

Pawl d

Switch

Pawl s

Overlo

Dirty c

Defect

Pawl s

Brake

Hook s

the hoiThe loastuck t

Brake

Brake

Foreig

Brake BremsDefect

ched to Chain

ng to the noiskwards - it shrds not forwa

ad

got stuck

linings are worn

chain is twisted

of chain, gear or cha

does not engage prope

ing pin - wrong positio

pring is missing

ad

hains, gear or chain w

of chain, gear or cha

pring is missing or de

spring is missing

stucks, chain is twisted

ist was unloaded withad hook was pulled aghere.

too tight

without function due t

n-object between the

lining is missing, instabelages or deformation

spring is missing or d

se it makes:hould make ard - it should

ain wheels

erly

on

wheels

ain wheels

efective

d

out lowering the load gainst the housing an

to rust

brake discs

alled incorrectly or wo

efective.

click d make click

Remedy

Reduce t

Set the loDo maintexchangAlign theDo maintspare paCheck th

Chose coDo maintspare paReduce t

Do maintDo maintspare paDo maintspare paDo maintspare paPlace ho

Suspendnd got Release

unload thTurn the move theside. Effect peRemove lubricate

orn Replace

Check anDo maintspare pa

C

the load to nominal lo

oad free again tenance and e the brake linings load chain tenance and replace drts e pawl and replace it

orrect position of switctenance and replace drts the load to nominal lo

tenance, lubricate chatenance and replace drts tenance and replace drts tenance and replace drts oks and chains in cor

the load again, lowerthe hook, suspend th

he hoist. switching pin to posite hand lever while pul

eriodic inspection and the foreign-object, cle.)

the brake lining resp.

nd replace, if necessatenance and replace drts.

CS.5.52.187

oad

defective parts by orig

if necessary

ching pin defective parts by orig

oad

ains, gear and chain wdefective parts by orig

defective parts by orig

defective parts by orig

rrect position

r the load, unload thehe load again, lower th

tion "▼" resp. "DN" alling the chain at the lo

replace rusty parts. ean the surface (Do n

. install it correctly

ary. defective parts by orig

.00.01.02

ginal

ginal

wheels ginal

ginal

ginal

hoist he load,

nd oad

not

ginal

-

CS.5.52

15 Pos: 19.2 /1_HADEF/---ALLGEMEIN/Hinweise/WARNUNG - Außerbetriebnahe: Sc

WIt is esseinjury whPos: 19.3 /1_HADEF/17-AUßERBETRIEBNAHME/Allgemein/Alle Außerbetriebnah

It is man First Read Disas Pleas

15.1 Meas Also

15.2 Meas After

in acc Pos: 20.1 /1_HADEF/19-Unterlagen auf Anforderung/*Ü1*/#. Kapitel - Unterlagen a

16 Pos: 20.2 /1_HADEF/19-Unterlagen auf Anforderung/Ketten+Ratschzüge/Montagea

InstallatiThese w Pos: 21.1 /2_CS/21-ERSATZTEILLISTE/*Ü1*/#.Kapitel - Ersatzteilliste @ 3\mod_1

.187.00.01.0

Decommchäden vermeiden.. @ 0\mod_1177597023398_52.docx @ 5591 @ @ 1

WARNINGential that thehen the devic

me @ 0\mod_1173431980767_52.docx @ 671 @ @ 1

ndatory that asecure the w

d the chapterssembly is case make sure

Temporarsures are as read the cha

Final decsures are as disassembly

cordance witauf Anforderung @ 0\mod_1178875504638_52.docx @ 6019 @ @ 1

Documeanweisung – Bremssystem 50/07 + 53/07 @ 0\mod_1178875622488_52.docx @ 6026 @ @ 1

on instructioworks may o

1421997561311_52.docx @ 28432 @ @ 1

02

missionin

G! e following pce is being d

all steps for dworking area r "Safety instarried out in e that all ope

ry decommabove.

apter “Transp

ommissionabove. y, ensure thath environme

ents availn – brake sy

only be done

ng

points are obecommission

decommissiofor decommructions". reverse orde

erating mater

missioning

port and stora

ning/dispos

at the disposental regulati

lable on rystem e by „qualie

bserved in orned:

oning the mamissioning, lea

er to the asserial is dispos

age”.

sal

sal of the eqons.

request

efied person

rder to preve

achine are caaving plenty

embly. ed of in acco

uipment and

ns“.

nt damage to

arried out in tof space.

ordance with

d any materia

to the equipm

the indicated

environmen

als it contain

ment or critic

d sequence:

ntal regulation

ns is carried

17

cal

ns.

out

-

18

17 Pos: 21.2 /2_CS/21-ERSA

=== Ende der Liste für Te

7 SpaATZTEILLISTE/Alle/CLLH @ 3\mod_1421998295289_52.docx @ 28469 @ @ 1

extmarke Inhalt ===

are Parts

List

CCS.5.52.187

.00.01.02

-

Notizen

-

Notizen