Substitute Natural Gas Production with direct Conversion ... · PDF fileund den Freiraum, der...

Transcript of Substitute Natural Gas Production with direct Conversion ... · PDF fileund den Freiraum, der...

Substitute Natural Gas Production with

direct Conversion of Higher Hydrocarbons

Erzeugung von Substitute Natural Gas mit direkter

Umsetzung von höheren Kohlenwasserstoffen

Der Technischen Fakultät der Universität Erlangen-Nürnberg

zur Erlangung des Grades

DOKTOR-INGENIEUR

vorgelegt von

Christoph Baumhakl

aus Graz

Als Dissertation genehmigt von der Technischen Fakultät der

Friedrich-Alexander-Universität Erlangen-Nürnberg

Tag der mündlichen Prüfung: 25.07.2014

Vorsitzende des Promotionsorgans: Prof. Dr.-Ing. habil. Marion Merklein

Gutachter: Prof. Dr.-Ing. Jürgen Karl

Prof. Dr. Wilhelm Schwieger

III

Vorwort/Acknowledgement

Die vorliegende Arbeit entstand im Zuge meiner Tätigkeit als wissenschaftlicher Mitarbeiter am

Institut für Wärmetechnik der Technischen Universität Graz und am Lehrstuhl für

Energieverfahrenstechnik der Friedrich-Alexander-Universität Erlangen-Nürnberg.

Ich möchte an dieser Stelle ganz herzlich Herrn Prof. Jürgen Karl für seine Betreuung und

Unterstützung bei dieser Arbeit bedanken. Im Besonderen aber auch für das optimale Arbeitsumfeld

und den Freiraum, der mir im Rahmen meiner Arbeit geboten wurde und maßgeblich zum Gelingen

beitrug. Besonderer Dank gilt auch Herrn Prof. Wilhelm Schwieger für die Übernahme des

Zweitgutachtens.

Großen Dank schulde ich meinem Mitstreiter im Kampf mit Vergasungsanlagen, Dr. Thomas

Kienberger, für die Einführung in die Vergasung und Methansynthese und die langen Diskussionen.

Meinen ehemaligen Kollegen, Dr. Lorenz Griendl, Dr. Martin Hauth, Bernhard Gatternig und

Dr. Andreas Schweiger danke ich ganz herzlich für ihre Hilfestellung beim Bau und Betrieb von

Versuchsanlagen.

Natürlich danke ich auch allen meinen anderen Kollegen für ihre Hilfe und offenen Ohren und das

freundschaftliche Verhältnis.

So eine Arbeit wäre ohne die Mitarbeit von Studenten im Rahmen von verschiedensten

Abschlussarbeiten nicht durchführbar. Dafür möchte ich ihnen auch ganz herzlich Danke sagen.

Großer Dank gilt natürlich meinen Eltern und meiner Familie, durch deren Motivation und

finanziellen Unterstützung meiner Ausbildung, ich erst so weit kommen konnte um diese

Doktorarbeit zu erstellen.

Dir Katrin gilt mein größter Dank; dass Du mich immer aufgeheitert und auf andere Gedanken

gebracht hast und ich durch Dich immer wieder aufs Neue zu meiner Arbeit motiviert worden bin.

Nürnberg, im April 2014 Christoph Baumhakl

A part of the research leading to these results has received funding from the European Community’s

Research Fund for Coal and Steel (RFCS) under grant agreement n° RFCR-CT-2009-00003.

Abstract

V

Abstract

This thesis gives a contribution to develop a methanation process for production of Substitute

Natural Gas (SNG) in small-scale, decentralized facilities. Smaller plant sizes require a reduction of

the plant complexity. Therefore, a reduced gas cleaning and simplified methanation process is

proposed. A reduced gas cleaning effort results in remaining of certain contaminations in the

synthesis gas. Consequently, the methanation catalyst must be able to deal with these species.

To investigate the influence of contaminations on the methanation, suitable test setups were

constructed to validate these influences experimentally. The tests were performed with artificial,

bottle-mixed synthesis gas as well as with real synthesis gas from allothermal gasification of biomass

and lignite. The gas composition for the tests with bottle-mixed syngas bases mainly on results from

gasification tests.

In a first step, bench-scale methanation tests with clean, bottle-mixed synthesis gas prove the

proposed polytropic fixed bed reactor concept for methanation. Results from long-term tests show a

full-conversion respectively yield down to 230°C without deactivation of the catalyst. Due to the

polytropic operation of the reactor, a temperature peak originates at its inlet. It is assumed that this

temperature peak provides the required heat for conversion of higher hydrocarbons.

The lab-scale tests with contaminated synthesis gas investigate the influence of typical synthesis gas

contaminations such as ethylene, tars and hydrogen sulfide. The tests confirm that higher

hydrocarbons are directly converted within methanation. Conversion tests with ethylene and tars

showed that they fully convert within the first centimeters of the reactor. Main problem thereby is

the coking of the catalyst.

Addition of higher 0.5 vol. % ethylene results in severe coking, whereas only minor coking occurred

by addition of a representative tar mixture with a concentration of 6-12 g/Nm³. The amount of

deposited carbon depends on the reactor temperatures and the water content of the syngas.

A combined conversion of ethylene and tars showed lower coking compared to conversion of

ethylene only. A further lowering as well as prevention of carbon deposition is possible by addition of

traces (< 1 ppm) of hydrogen sulfide.

In the last step, the whole SNG production process, containing gasification, gas cleaning and

methanation is demonstrated in bench-scale. The simplified gas cleaning removes sufficiently dust,

alkalis and sulfur species such as H2S and COS, but has probably weaknesses with organic sulfur.

Therefore, the measured catalyst deactivations are high, which requires further improvements.

Promising is the almost full conversion of tars during methanation with real synthesis gas.

Kurzfassung

VI

Kurzfassung

Diese Arbeit beschäftigt sich mit verschiedenen Aspekten zur Entwicklung eines Prozesses zur

Erzeugung von Substitute Natural Gas (SNG) in kleinen, dezentralen Anlagen. Um auch im kleineren

Leistungsbereich wirtschaftlich sein zu können, muss die Anlagenkomplexität reduziert werden.

Daher wird in dieser Arbeit ein Prozess mit einer reduzierten Gasreinigung und vereinfachter

Methanisierung vorgeschlagen. Durch den reduzierten Gasreinigungsaufwand verbleiben bestimmte

Verunreinigungen im Synthesegas und beeinflussen die Methanisierung.

Zur Untersuchung des Einflusses von Verunreinigungen auf die Methansynthese wurden geeignete

Versuchsanordnungen aufgebaut und die Einflüsse experimentell ermittelt. Dabei sind sowohl

künstliche, flaschengemischte Synthesegase aber auch reale Synthesegase aus der thermischen

Vergasung verwendet worden. Die Gaszusammensetzung bei den Tests mit flaschengemischten

Gasen basiert hauptsächlich auf Ergebnissen aus Vergasungstests.

In einem ersten Schritt bestätigen Tests mit sauberen, flaschengemischten Synthesegasen die

Eignung des vorgeschlagenen polytropen Festbettreaktor Konzepts für die Methanisierung.

Langzeittests zeigen eine Aktivität des gewählten Katalysators bis runter zu 230°C, wobei ein

vollständiger Umsatz ins thermodynamische Gleichgewicht möglich ist. Zeichen für eine

Deaktivierung des Katalysators waren dabei nicht erkennbar. Durch die polytrope Betriebsweise des

Reaktors bildet sich ein Temperaturpeak in der Eintrittszone des Reaktors aus. Es wird vermutet, dass

dieser Temperaturpeak genügend Wärme für den Umsatz von höheren Kohlenwasserstoffe im Zuge

der Methanisierung liefert.

Labortests mit flaschengemischten Synthesegas unter Zugabe verschiedener Verunreinigungen wie

Ethylen, Teere und Schwefelwasserstoff zeigen den Einfluss dieser Komponenten auf die

Methanisierung. Die Ergebnisse bestätigen, dass höhere Kohlenwasserstoff direkt im Zuge der

Methansynthese umgesetzt werden. Untersuchungen des Umsatzes zeigen, dass dies innerhalb der

ersten Zentimeter des Reaktors geschieht. Hauptproblem dabei ist aber die Verkokung des

Katalysators.

Die Zugabe von mehr als 0.5 vol. % Ethylen führt zu starker Verkokung, wohingegen Teere in

Konzentrationen von 6-12 g/Nm³ nur zu geringen Kohlenstoffablagerungen am Katalysator führten.

Die Menge des abgelagerten Kohlestoffs hängt von den Reaktortemperaturen aber auch dem

Wasseranteil des Synthesegases ab.

Ein kombinierter Umsatz von Ethylen und Teeren zeigte, im Vergleich zum Umsatz von Ethylen

alleine, geringere Verkokung. Diese Verkokung lässt sich weiter reduzieren, beziehungsweise

vermeiden, durch die Zugabe von geringen Mengen (< 1 ppm) Schwefelwasserstoff.

Im letzten Teil der Arbeit wurde die gesamte Prozesskette der SNG-Produktion, von der Vergasung,

über die Gasreinigung, bis zur Methanisierung, im Labormaßstab erprobt. Die vereinfachte

Gasreinigung entfernt effektiv Staub, Alkalien und Schwefelverbindungen wie H2S und COS, hat aber

wahrscheinlich Schwächen bei der Abscheidung von organischen Schwefelverbindungen. Das zeigt

sich auch in den noch recht hohen Deaktivierungsraten des Katalysators. Eine weitere Optimierung

der Entschwefelung ist deshalb erforderlich. Vielversprechend ist der fast vollständige Umsatz von

Teere auch in den Tests mit realem Synthesegas.

Content

VII

Content

1. Introduction ......................................................................................................................... 1

1.1. Motivation ............................................................................................................................... 1

1.2. Objectives ................................................................................................................................ 3

2. State-of-the-Art .................................................................................................................... 5

2.1. Reactor concepts for methanation ......................................................................................... 6

2.2. Large SNG plants and projects in operation ............................................................................ 9

2.2.1. Large-scale coal-to-SNG plants ........................................................................................ 9

2.2.2. Biomass-to-SNG projects ............................................................................................... 10

2.2.3. Future large SNG plants and projects ............................................................................ 13

3. Theoretical Background ...................................................................................................... 15

3.1. Gasification ............................................................................................................................ 15

3.1.1. Allothermal gasification with water steam ................................................................... 16

3.1.2. Tar problematic of thermal gasification ........................................................................ 18

3.1.3. Contaminations in the product gas from allothermal gasification ............................... 19

3.2. Hot gas cleaning for sulfur and chlorine removal ................................................................. 21

3.2.1. Adsorptive desulfurization with metal oxides ............................................................... 21

3.2.2. Desulfurization with activated carbons ......................................................................... 23

3.3. Methanation .......................................................................................................................... 24

3.3.1. Thermodynamics ........................................................................................................... 25

3.3.2. Reaction kinetics and mechanisms ............................................................................... 27

3.3.3. Reforming of higher hydrocarbons ............................................................................... 29

3.3.4. Theoretical and practical aspects for the reactor design .............................................. 33

4. Catalyst Deactivation and Carbon Deposition ...................................................................... 35

4.1. Deactivation mechanisms ..................................................................................................... 35

4.2. Carbon deposition ................................................................................................................. 36

4.2.1. Types of carbon deposits and reactions ........................................................................ 36

4.2.2. Thermodynamics of carbon formation ......................................................................... 39

4.2.3. Possibilities for regeneration of carbon deposits .......................................................... 43

4.2.4. Measurement methods for carbon deposition ............................................................. 44

4.3. Poisoning ............................................................................................................................... 49

Content

VIII

4.3.1. Poisoning by sulfur ........................................................................................................ 49

4.3.2. Regeneration of sulfur-poisoned catalysts .................................................................... 50

4.4. Thermal degradation ............................................................................................................. 50

4.5. Evaporation – nickel tetracarbonyl ....................................................................................... 51

5. Bench-Scale Methanation Tests with Clean Syngas – Polytropic Reactor Concept.................. 53

5.1. Experimental setup ............................................................................................................... 53

5.2. Catalysts for methanation ..................................................................................................... 55

5.3. Test procedure ...................................................................................................................... 56

5.4. Methanation tests with different catalysts ........................................................................... 57

5.4.1. Basic performance screening ........................................................................................ 57

5.4.2. Detailed catalyst screening ........................................................................................... 59

5.4.3. Long-term performance of catalysts ............................................................................. 62

5.5. Conclusion bench-scale methanation tests........................................................................... 63

6. Experimental Investigations with Bottle-Mixed Contaminated Syngas – Experimental Setup 65

6.1. Investigation focus and program ........................................................................................... 65

6.1.1. Definition of investigation parameters ......................................................................... 65

6.1.2. Test program and procedure......................................................................................... 67

6.2. Test rig assembly ................................................................................................................... 68

6.2.1. Gas mixing station with tar conditioning unit ............................................................... 68

6.2.2. Methanation reactor test rig ......................................................................................... 71

6.2.3. Gas and tar analysis and measurement techniques ..................................................... 73

7. Experimental Investigations with Bottle-Mixed Contaminated Syngas – Results ................... 81

7.1. Parameter variations with non-contaminated synthesis gas ................................................ 81

7.2. Parameter variations with aliphatic hydrocarbons – Ethylene ............................................. 83

7.2.1. Behavior of carbon on the catalyst ............................................................................... 83

7.2.2. Definition of a critical/acceptable carbon content ....................................................... 86

7.2.3. Influence on ethylene-promoted carbon deposition .................................................... 89

7.3. Parameter variations with representative tar mixtures........................................................ 91

7.4. Reduction of carbon deposition by addition of sulfur species .............................................. 97

7.5. Visual evaluation of carbon deposits .................................................................................. 100

7.6. Summary and conclusion bottle-mixed syngas tests .......................................................... 102

Content

IX

8. Bench-Scale Tests with Real Synthesis Gas Produced in Allothermal Gasification ................. 103

8.1. Investigation focus and program ......................................................................................... 103

8.2. Test rig assembly and setup ................................................................................................ 103

8.2.1. Test rig assembly ......................................................................................................... 103

8.2.2. Test setup and operating conditions ........................................................................... 107

8.3. Results ................................................................................................................................. 110

8.3.1. Gasification .................................................................................................................. 110

8.3.2. Adsorptive hot gas cleaning ........................................................................................ 113

8.3.3. Methanation ................................................................................................................ 114

9. Conclusion ......................................................................................................................... 121

10. References ......................................................................................................................... 124

Figures

XI

Figures

Figure 1.1: General process steps for the production of SNG .............................................................. 1

Figure 1.2: Simplified flow sheet for the proposed SNG production process with hot gas cleaning ... 2

Figure 2.1: First patent for a catalytic methanation apparatus from Elworthy, 1905 .......................... 5

Figure 2.2: Different reactor concepts and processes for methanation of synthesis gas .................... 6

Figure 2.3: Simplified flow sheet of the DGC Great Plains synfuels plant ............................................ 9

Figure 2.4: Simplified flow sheet of SNG production in the FICFB gasification plant ......................... 11

Figure 2.5: Conceptual design of the HPR and idea for decentralized SNG production..................... 12

Figure 3.1: Simulation of the influence of σ on the permanent gas composition (dry basis) for allothermal gasification .................................................................................................... 17

Figure 3.2: Typical concentrations of gaseous contaminates from gasification of woody biomass and lignite with the measured contaminates from the lab-scale allothermal gasifier .... 20

Figure 3.3: H2S equilibrium desulfurization concentrations for different sorbents with standard synthesis gas composition with 100 ppm H2S .................................................................. 21

Figure 3.4: Influence of temperature on the equilibrium composition of H2/CO=3 at 1 bar. ............ 25

Figure 3.5: Influence of pressure on the equilibrium composition of an H2/CO=3 at 300°C.............. 26

Figure 3.6: Influence of temperature on the equilibrium composition of the standard synthesis gas composition used and on the chemical efficiency ..................................................... 26

Figure 3.7: Influence of the H2O content on the equilibrium composition of the standard synthesis gas composition used at 250°C and atmospheric pressure .............................. 27

Figure 3.8: Model of the Langmuir-Hinshelwood approach for the methanation reaction ............... 28

Figure 3.9: Model of a combined L-H and E-R approach for the water-gas-shift reaction................. 29

Figure 3.10: Model of the reaction mechanism for the reforming of ethane ...................................... 30

Figure 3.11: Model for hydrocracking of phenanthrene and naphthalene .......................................... 31

Figure 3.12: Reforming of benzene, toluene and naphthalene in model gas over a Ni catalyst .......... 32

Figure 4.1: Forms of carbon deposits on Ni surfaces.......................................................................... 36

Figure 4.2: Reaction paths for formation, gasification and transformation of coke and carbons ..... 37

Figure 4.3: Steps of growth of carbon filaments ................................................................................ 38

Figure 4.4: C-H-O ternary plot with phase equilibrium lines for solid carbon. ................................... 39

Figure 4.5: Rates of formation and hydrogenation of C and C species ........................................... 41

Figure 4.6: Temperature dependency of carbon deposition on Ni, 1-butene propene in hydrogen . 42

Figure 4.7: Typically observed reactor differential pressure trends resulting from coking ............... 44

Figure 4.8: SEM-photos of different carbon deposit forms ................................................................ 45

Figure 4.9: Flow sheet of the TPO setup to determine carbon deposits ............................................ 45

Figure 4.10: Results of TPO analysis of a methanation catalyst without carbon deposits ................... 47

Figure 4.11: Results of TPO analysis of a methanation catalyst with severe carbon deposits ............. 47

Figure 4.12: Displacement of the reactor temperature profile due to selective deactivation ............ 49

Figure 4.13: Equilibrium concentration for Ni(CO)4 for different CO concentrations .......................... 51

Figure 5.1: Simplified flow sheet of the bench-scale methanation test rig ........................................ 53

Figure 5.2: 3D drawing of the tube reactor and sketch with positions of thermocouples................. 54

Figure 5.3: Temperature profiles of the tested catalysts ................................................................... 57

Figures

XII

Figure 5.4: Gas composition measured at various points of the reactor compared to temperature-related equilibrium gas compositions for EVT05 ........................................ 58

Figure 5.5: H2 content in the product gas for different catalysts at varying synthesis gas H2O contents .................................................................................................................... 59

Figure 5.6: H2 content in the product gas in dependency of the reactor outlet temperature and the water content with EVT01 .......................................................................................... 59

Figure 5.7: H2 content in the product gas in dependency of the reactor outlet temperature and the water content with EVT05 .......................................................................................... 60

Figure 5.8: H2 content in the product gas in dependency of the GHSV and the water content with EVT01 ............................................................................................................................. 61

Figure 5.9: H2 content in the product gas in dependency of the GHSV and the water content with EVT05 ............................................................................................................................. 61

Figure 5.10: Reactor temperatures for a long-term test with EVT01 ................................................... 62

Figure 5.11: Gas composition for a long-term test with EVT01 ............................................................ 63

Figure 6.1: Parameters influencing methanation ............................................................................... 66

Figure 6.2: Photo of the test rig for tests with bottle-mixed, contaminated synthesis gases ............ 68

Figure 6.3: Flow sheet of the gas mixing station with tar conditioning unit ...................................... 69

Figure 6.4: User interface of the control system ................................................................................ 71

Figure 6.5: Flow sheet of the methanation reactor test rig ............................................................... 72

Figure 6.6: 3D-drawing of the reactor oven with the reactors ........................................................... 72

Figure 6.7: Flow sheet of gas analyzing unit ....................................................................................... 73

Figure 6.8: UV absorption tar measuring cell ..................................................................................... 77

Figure 6.9: Configuration for SPA sampling ........................................................................................ 79

Figure 7.1: Measured axial temperature profiles over the reactor at different reactor oven temperatures .................................................................................................................... 82

Figure 7.2: Resulting reactor temperatures in dependency of the reactor oven temperatures ........ 82

Figure 7.3: Carbon deposition on the catalyst at 300°C using different C2H4 contents ..................... 84

Figure 7.4: Carbon deposition on the catalyst at 320°C using different C2H4 contents ..................... 84

Figure 7.5: Carbon deposition on the catalyst at 370°C using different C2H4 contents ..................... 85

Figure 7.6: Temperature profiles of a test with high carbon deposition ............................................ 85

Figure 7.7: Differential pressure across the reactor during a test with high carbon deposition ....... 86

Figure 7.8: Relation of differential pressure and the amount of carbon deposited in the reactor .... 87

Figure 7.9: Photographs of catalyst samples with different amounts of deposited carbon .............. 88

Figure 7.10: Specific amounts of catalyst consumption and cost ........................................................ 89

Figure 7.11: Influence of temperature on the amount of deposited carbon ....................................... 90

Figure 7.12: Deposited carbon in dependency of the temperature and the C2H4 content .................. 91

Figure 7.13: Amount of deposited carbon in dependency of the temperature and the H2O content, syngas with standard tar concentration ........................................................................... 92

Figure 7.14: Amount of deposited carbon in dependency of the temperature and the tar concentration .................................................................................................................... 93

Figure 7.15: Tar conversion during a methanation test in dependency of the reactor temperature .. 93

Figure 7.16: Tar conversion during a methanation test with reduced catalyst filling .......................... 94

Figure 7.17: Influence of methanation conditions on the conversion of toluene ................................ 95

Figures

XIII

Figure 7.18: Amount of deposited carbon resulting from methanation with simultaneous addition of C2H4 and tars compared to separate addition .............................................................. 95

Figure 7.19: Measured catalyst degradation from poisoning with H2S for EVT05 .............................. 98

Figure 7.20: Specific catalyst consumption and related catalyst cost due to poisoning with H2S ....... 98

Figure 7.21: Influence of C2H4 and H2S on the amount of deposited carbon ....................................... 99

Figure 7.22: Influence of a C2H4, tars and H2S on the amount of deposited carbon ............................ 99

Figure 7.23: States of polymeric carbon coverage on a catalyst pellet .............................................. 100

Figure 7.24: SEM photos of polymeric carbon deposits on the catalyst resulting from C2H4 ............ 100

Figure 7.25: SEM photos of polymeric carbon filaments resulting from C2H4 .................................... 101

Figure 7.26: SEM photos of polymeric carbon layers resulting from C2H4 ......................................... 101

Figure 8.1: Photo of the bench-scale test rig for SNG production with real synthesis ..................... 104

Figure 8.2: Flow sheet of the indirectly heated, fluidized bed gasifier ............................................ 105

Figure 8.3: Flow sheet of the bench-scale hot gas cleaning and methanation unit ......................... 106

Figure 8.4: Flow sheet of the gas analysis unit for methanation and gasification tests ................... 107

Figure 8.5: Mean dry permanent gas composition from gasification of biomass and lignite .......... 110

Figure 8.6: Mean wet permanent gas composition from gasification of biomass and lignite ......... 111

Figure 8.7: Mean C2-C4 content from gasification of woody biomass and lignite ............................ 111

Figure 8.8: Mean tar concentrations from gasification of woody biomass and lignite .................... 112

Figure 8.9: Mean contaminations from gasification of woody biomass and lignite ........................ 113

Figure 8.10: Comparison of the mean contaminations resulting from gasification of lignite before and after hot gas desulfurization with ZnO .................................................................... 113

Figure 8.11: Trend of the permanent gas composition after methanation ....................................... 114

Figure 8.12: Measured tar concentration after methanation and the related tar conversion .......... 115

Figure 8.13: Trend of the differential pressure across the methanation reactor .............................. 115

Figure 8.14: Measured catalyst carbon contents at different points of the methanation reactor .... 116

Figure 8.15: SEM-photos of polymeric carbon filaments on a catalyst sample taken after longtime real gas tests ................................................................................................................... 117

Figure 8.16: SEM-photos of laminar (graphitic) carbon deposits on a catalyst sample taken after longtime real gas tests .................................................................................................... 117

Figure 8.17: SEM-photo of cracks on a catalyst tab after 200 h runtime with real synthesis gas ...... 117

Figure 8.18: Axial temperature trends in the methanation reactor for different runtimes ............... 118

Figure 8.19: Measured catalyst degradation for tests 1-5.................................................................. 119

Figure 8.20: Measured specific catalyst consumptions for tests 1-5 ................................................. 120

Figure 9.1: Influence of contaminations on the specific amount of catalyst consumption ............. 121

Figure 9.2: Influence of sulfur concentration and ethylene content on catalyst consumption ....... 122

Tables

XIV

Tables

Table 2.1: Typical gas compositions of the FICFB gasifier, operated with wood chips ...................... 10

Table 2.2: Overview of gasification systems proposed for specific SNG projects .............................. 13

Table 3.1: Standard synthesis gas composition for the methanation tests ....................................... 17

Table 3.2: Tar classes according to ECN ............................................................................................. 18

Table 3.3: Overview of commercially available impregnated activated carbons............................... 23

Table 4.1: Overview of mechanisms of catalyst deactivation ............................................................ 35

Table 4.2: Carbon species formed on Ni catalyst ............................................................................... 37

Table 4.3: TPO method for a quantitative and qualitative analysis of carbon deposits .................... 46

Table 5.1: Overview of the catalysts used for the methanation tests ............................................... 55

Table 5.2: Standard reducing procedure ............................................................................................ 56

Table 6.1: Overview of parameters for the methanation tests .......................................................... 67

Table 6.2: Constants for Antoine equations of different tar species ................................................. 70

Table 6.3: Overview of used µ-GC-modules ....................................................................................... 75

Table 6.4: Parameters for the standard µ-GC method ....................................................................... 75

Table 6.5: Overview of the most commonly used detector tubes ..................................................... 78

Table 8.1: Fuel parameters for the used lignite and biomass .......................................................... 108

Table 8.2: Operating parameters for the real gas methanation tests .............................................. 108

Nomenclature

XV

Nomenclature

Abbreviations

BTX Benzene toluene xylene

CHP Combined heat and power

CNG Compressed natural gas

DGC Dakota Gasification Company

DVGW Deutscher Verein des Gas-und Wasserfaches

ECN Energy Research Center of the Netherlands

EDX Energy -dispersive X-ray analysis

E-R Eley-Rideal

EVT Institute for Energy Process Engineering, University Erlangen-Nurenberg

FICFB Fast internal circulating fluidized bed

FID Flame ionization detector

GA Gas analyzer

GC Gas chromatograph

GHSV Gas hourly space velocity

GoBiGas Gothenburg Biomass Gasification

HGR Hot gas recycle

HPR Heatpipe-Reformer

IGCC Integrated gasification combined cycle

IGT Institute of Gas Technology (GTI)

IPA Isopropyl alcohol

LED Light emitting diode

L-H Langmuir-Hinshelwood

LHV Lower heating value

MFC Mass flow controller

NDIR Non-dispersive infrared

PAH Polycyclic aromatic hydrocarbons

PSI Paul-Scherrer-Institute

RFCS Research Fund for Coal and Steel

RME Rapeseed methyl ester

S/C Steam to carbon

SEM Scanning electron microscopy

SNG Substitute natural gas

SPA Solid phase adsorption

SPE Solid phase extraction

TGA Thermo gravimetric analysis

TOF Turnover frequency

TPO Thermo programmed oxidation

TREMP Topsøes recycle methanation process

TU Technical University

TWR Tube wall reactor

UV Ultra violet

WGS Water-gas shift

Nomenclature

XVI

Latin symbols

aCatalyst Active catalyst area

an,Catalyst Normalized active catalyst area

Aλ Absorbance [-]

b Optical path length [m]

c Molar concentration [mol/l]

CC Carbon content [mgCarbon/gCatalyst]

cCat. Specific catalyst costs [€ct/kWhSyngas]

CCat. Catalyst costs [€/kg]

dP Catalyst particle diameter

dR Inner reactor diameter

GHSV Gas hourly space velocity [h-1]

I0 Intensity of the incident light [W/m²]

I1 Intensity of the transmitted light [W/m²]

L Reactor length

LHV Lower heating value [kJ/kg] or [kJ/mol]

mCat. Catalyst mass [g]

ni Mole content

ni Molar flow rate

p Pressure [Pa]

pi Partial pressure [Pa]

PSG Synthesis gas power [kW]

T Temperature [°C]

t Time [h] tOp. Catalyst operation time [h]

VReactor Reactor volume [m³]

VStd Standard volume flow [m³/h]

xH2O,min Minimal required mass of water [kgH2O/kgFuel]

X Conversion [-]

Greek symbols

ΔHR Reaction enthalpy [kJ/mol]

ελ Molar absorption coefficient [l mol-1 m-1]

ηMeth Chemical efficiency for methanation [-]

λ Air ratio [-]

σ Excess steam ratio [-]

Introduction

1

Chapter 1

1. Introduction

1.1. Motivation

The worldwide increasing consumption of energy requires new or improved technologies for

supplying the demand. Besides security of supply and public acceptance, the influence on the

environment and world climate in particular, has become a central issue. Production of Substitute

Natural Gas (SNG) from biomass could be one way of addressing these issues. SNG has several

advantages, such as the high conversion efficiency and the possibility to use the existing gas grid for

distribution and storage. Typically, larger amounts of biomass are available in rural areas with a

relatively low population density and therefore low energy demand. Since biomass has a low energy

density, transportation over long distances is hardly economical and ecologically sustainable. Thus,

the maximum plant size for biomass applications is limited [1]. In addition, direct transportation of

biomass into areas with higher energy needs, such as urban areas, is not convenient. Small-scale,

decentralized production of SNG and feed-in into the gas grid enables indirect transportation of solid

fuels via the gas grid. Additionally, smaller plants facilitate the utilization of waste heat.

Energy production processes are highly influenced by the economies-of-scale principle [2], which

implies that increased plant power significantly reduces production costs. Since plant power for

biomass applications is limited, alternative ways of making them economically viable need to be

found. A simplified downscaling of state-of-the-art, large-scale processes is generally not possible. It

is also necessary to reduce the complexity of plants. Therefore, this thesis proposes a simplified

process for the production of SNG.

Figure 1.1: General process steps for the production of SNG

The production process of SNG typically consists of four essential steps (figure 1.1): synthesis gas

production, gas cleaning, methanation and gas conditioning. Synthesis gas is produced by gasifying a

solid fuel. In the gas cleaning step contaminates such as particles, alkalis or sulfur, are removed prior

to methanation. In the methanation step, the synthesis gas is then catalytically converted to

raw-SNG. Before feed-in into the gas grid or alternative usage, it is necessary to condition the gas,

e.g. by removing CO2 and H2O or by odorization.

Thermalgasification

Gas cleaning MethanationGas

conditioning

Fuel H2O

Heat/O2

H2O/CO2

SNG

Introduction

2

State-of-the-art large-scale plants for SNG production, such as the Dakota Gas synfuels plant [3], put

a lot of effort into removing all impurities from the synthesis gas. This is only feasible by using

cold/wet gas cleaning methods such as Rectisol scrubbing. Operators of the Dakota Gas synfuels

plant described this as the ‘bottleneck’ in SNG production as it is the largest utility consumer in the

plant [3]. The most demonstrated or planned gas cleaning technology for biomass-scale SNG plants is

a combination of tar scrubbing (cold with bio oil) and adsorptive dechlorination and desulfurization

[4]. This is quite complex too and has not reached a commercial state yet.

To achieve a reduction of plant complexity, this thesis proposes the usage of hot gas cleaning

techniques. A reduction of exergetic losses, which are due to the high temperature level of waste

heat, is also advantageous. The main steps in hot synthesis gas cleaning are particle filtration and

different catalytic and adsorptive processes. The bioliq-plant [5] demonstrates such a process. Due to

the tar-free gasification by means of an entrained flow gasifier, tars do not need to be considered in

the gas cleaning process. Other gasification systems do not have this advantage. The SNG production

concept proposed in this thesis is based on indirectly heated fluidized bed gasification. Therefore, the

presence of tars and other higher hydrocarbons is an important issue to consider. The approach of

this thesis is to not remove tars and other hydrocarbons from the synthesis gas. Thus, the

methanation catalyst must be able to deal with these components. For methanation, this thesis

proposes a partially cooled, tubular fixed bed reactor. Due to the polytropic temperature profile

inside the reactor, the temperature peak that occurs at the inlet provides the heat needed for the

conversion of the hydrocarbons.

Figure 1.2 shows a possible option for SNG production by means of hot gas cleaning. After

gasification, a hot gas filter (ceramic or sinter metal) removes particles and ash. If the filter

temperature is sufficiently low (550-350°C), alkalis will condensate on the filter cake. Sulfur and

chlorine components can be adsorbed by means of different adsorptive materials such as zinc oxide

or activated carbons. Afterwards, the still tar-loaded synthesis gas is fed into the methanation

reactor. The central issue of the proposed SNG production concept is how the methanation catalyst

performs with higher hydrocarbons that are present in the synthesis gas.

Figure 1.2: Simplified flow sheet for the proposed SNG production process with hot gas cleaning

The proposed concept was developed on the basis of allothermal biomass gasification, as used in the

Heatpipe-Reformer (HPR) [6], [7] or in the FICFB-gasifier (Güssing) [8], [9]. However, the results of

this thesis do not only apply to allothermal biomass gasification systems. By considering the

boundary conditions, they can be also transferred, or partially transferred, to other concepts of

synthesis gas production.

Gasifier

Steam

Fuel

Heat

Ash

Hot gas filter

Adsorptive gas cleaning

Methanation Gas conditioning

SNG

CO2H2O

Introduction

3

1.2. Objectives

The main objective of this thesis is to gain a better understanding of the methanation process and

the influences of higher hydrocarbons and tars on the methanation catalysts for simplified systems

with hot gas cleaning in particular. The methanation process has been investigated and used for

more than 100 years. However, previous applications, like CO removal from town gas or methanation

of synthesis gas from oxygen-blown gasifiers, had other aspects to consider than the methanation

step of the concept proposed here. Therefore, additional investigations are necessary.

Bench-scale methanation tests with clean, bottle-mixed synthesis gas

In a first step methanation tests with clean, bottle-mixed synthesis gas prove the polytropic reactor

concept for methanation. By screening of different commercial as well as experimental nickel-based

catalysts, an appropriate catalyst was chosen for detailed investigations (chapter 5).

Influence of higher hydrocarbons and syngas contamination

The major part of this work is dedicated to a detailed analysis of the influence of higher

hydrocarbons on methanation. Previous investigations by Kienberger [10] showed that a direct

conversion of hydrocarbons is possible during methanation, but is accompanied by deactivation of

the catalyst and coking. To reduce or prevent such negative effects, a more detailed understanding

of the processes is helpful. Therefore, methanation tests with bottle-mixed synthesis gas with

addition of different hydrocarbons were performed (chapter 7). The evaluation of these tests is

based on measured deactivation rates, amounts of carbon deposited as well as conversion rates. A

first test series investigates the manner of carbon deposition, and, in particular, how runtime and the

amount of deposited carbon correlate. If this correlation is known, the number of long-term tests can

be significantly reduced by substituting them with short-term (e.g. one-day) tests. From the test

results, conclusions can also be drawn about the amount of carbon that is acceptable on the catalyst.

With the information from this first test series, further tests analyze the influence of different

parameters on the amount of deposited carbon. Parameters to vary are the reaction temperature,

the concentration of hydrocarbons in the feed and the amount of water. The permanent gas

composition, derived from allothermal gasification of biomass, was kept constant for all tests. The

results enable the definition of operating limits for methanation with sufficiently low coking and

deactivation of the catalyst, and they also provide options for reducing carbon deposits.

Bench-scale demonstration of the SNG process

The whole SNG production process, consisting of gasification, gas cleaning and methanation, is

demonstrated in a bench-scale (chapter 8). These experimental validations focus on the performance

of the catalyst using real synthesis gas from allothermal gasification. The operating conditions for

these tests are set in accordance with the results of the detailed investigations made with bottle-

mixed synthesis gas. The results provide information about catalyst degradation rates, amounts of

deposited carbon as well as gas composition, including contaminates, at all points of the process.

For all tests it was necessary to develop, design and construct suitable test rigs and setups.

Additionally, methods of analyzing different deposits and contaminations, e.g. coke, sulfur,

hydrocarbons or tars had to be developed or applied.

State-of-the-Art

5

Chapter 2

2. State-of-the-Art

The production of combustible gases from a solid fuel, mainly coal, has a long tradition. At the

beginning 19th century, the first gas grids were established in several European and North American

cities. The first commercial gas works started its operation in London in 1812 [11]. In the early years

town gas was mainly the product of gasified pyrolysis gases. The invention of the water-gas

generator by Carl Wilhelm Siemens in the middle of the 19th century, allowed the utilization of coke

too. At end of the 19th century, a town gas composition of around 50 vol. % hydrogen, 25 vol. %

methane, 10 vol. % carbon monoxide and various amounts of carbon dioxide, nitrogen, oxygen and

hydrocarbons had become established [12].

In 1897, Bone et al. [13] published first experiments of the formation of methane from carbon and

hydrogen. They reported that, at a temperature of around 1200°C, carbon unites directly with

hydrogen to form methane without formation of other hydrocarbons. In 1902, Sabatier and

Senderens [14] reported the first catalytic methanation. They discovered that a mixture of one part

carbon monoxide and three parts hydrogen undergoes complete conversion into methane and water

when passing reduced nickel at 250°C. The same happened with carbon dioxide and methane at

higher temperatures. Elworthy [15] identified the commercial potential of this discovery and applied

for several patents (figure 2.1) for the technical implementation of methanation.

Figure 2.1: First patent for a catalytic methanation apparatus from Elworthy, 1905 [15]

The commercial exploitation of Elworthy’s inventions failed due to a lack in demand for methane.

Feed-in into existing gas grids would have required replacing or modifying the majority of utilization

devices. Fischer and Tropsch were investigating the methanation of coal-derived synthesis gas when

State-of-the-Art

6

they discovered the formation of long-chain hydrocarbons, the basis for the Fischer-Tropsch process

[16]. Until the early 1960s several investigations into methanation were carried out; however, the

focus of both research and commercial activities remained on the liquefaction of solid fuels.

From the 1960s, many states began to switch from town gas to natural gas. Even in those days there

was already an awareness of the finiteness of oil and natural gas. Furthermore, many countries did

not want to become too dependent on other countries in terms of energy supply and began to

facilitate the utilization of domestic coal and lignite. At that time methanation moved into the focus

of research. The first energy crisis in 1973 also led to the emergence of commercial interests. The

majority of the different methanation concepts have their origins in the 1970s and early 80s.

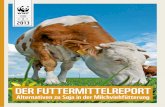

2.1. Reactor concepts for methanation

Basically, four different concepts have been demonstrated for methanation (figure 2.2): adiabatic

fixed bed reactors, cooled reactors (isothermal reactors), three-phase methanation and fluidized bed

methanation. Kopyscinski et al. [4] and Karl et al. [12] give a detailed review on methanation

concepts and concepts for SNG production.

Figure 2.2: Different reactor concepts and processes for methanation of synthesis gas, according to [12]

3-Phasen-Wirbelschicht

Synthesegas

(CO, H2)

methanreiches Produktgas

Synthesegas/ Produktgas

(gasförmig)

Katalysator-Partikel

(fest)

ca. 70 bar

Zwischenkühlung

inertes Trägeröl

(flüssig)

Trägeröl-

Rezirkulation

Separatordruckaufgeladene Wirbelschicht

Synthesegas

(CO, H2)

methanreiches Produktgas

Synthesegas/ Produktgas

(gasförmig)

Katalysator-Partikel

(fest)

bis ca. 70 bar

Kühlung

adiabate Festbett-

katalysatoren

Synthesegas

(CO, H2)

methanreiches Produktgas

Produktgas-rezirkulation

gestufte Edukt-zugabe

Zwischenkühlung

Zwischenkühlungca. 300-400°C

bis 600°C

gestufte Edukt-zugabe

Beispiel:

Synthane Hot Tube ReactorThermoöl-

Kühlung

Synthesegas

(CO, H2)

methanreiches Produktgas

ca. 400°C

adiabate Festbettreaktoren gekühlte Reaktoren Beispiel:

Synthane Hot Tube Reactor

Beispiel:

Lurgi Methanation

Beispiel:

Thyssen Comflux-Verfahren

Beispiel:

Chem Systems Liquid Phase Methanation

Flüssigphasen-Methanierung Wirbelschicht-Methanierung

adiabatic fixed beds

syngas

recycle compressor

intercooling staged feed injection

staged feed injection

intercooling

raw-SNG

ca. 300-400°C

up to 600-700°C

Adiabatic fixed bed reactors

e.g. Lurgi methanation process

3-Phasen-Wirbelschicht

Synthesegas

(CO, H2)

methanreiches Produktgas

Synthesegas/ Produktgas

(gasförmig)

Katalysator-Partikel

(fest)

ca. 70 bar

Zwischenkühlung

inertes Trägeröl

(flüssig)

Trägeröl-

Rezirkulation

Separatordruckaufgeladene Wirbelschicht

Synthesegas

(CO, H2)

methanreiches Produktgas

Synthesegas/ Produktgas

(gasförmig)

Katalysator-Partikel

(fest)

bis ca. 70 bar

Kühlung

adiabate Festbett-

katalysatoren

Synthesegas

(CO, H2)

methanreiches Produktgas

Produktgas-rezirkulation

gestufte Edukt-zugabe

Zwischenkühlung

Zwischenkühlungca. 300-400°C

bis 600°C

gestufte Edukt-zugabe

Beispiel:

Synthane Hot Tube ReactorThermoöl-

Kühlung

Synthesegas

(CO, H2)

methanreiches Produktgas

ca. 400°C

adiabate Festbettreaktoren gekühlte Reaktoren Beispiel:

Synthane Hot Tube Reactor

Beispiel:

Lurgi Methanation

Beispiel:

Thyssen Comflux-Verfahren

Beispiel:

Chem Systems Liquid Phase Methanation

Flüssigphasen-Methanierung Wirbelschicht-Methanierung

syngas

raw-SNG

heat-transfer-fluid cooling

ca. 400°C

Cooled reactors

e.g. Synthane hot tube reactor

3-Phasen-Wirbelschicht

Synthesegas

(CO, H2)

methanreiches Produktgas

Synthesegas/ Produktgas

(gasförmig)

Katalysator-Partikel

(fest)

ca. 70 bar

Zwischenkühlung

inertes Trägeröl

(flüssig)

Trägeröl-

Rezirkulation

Separatordruckaufgeladene Wirbelschicht

Synthesegas

(CO, H2)

methanreiches Produktgas

Synthesegas/ Produktgas

(gasförmig)

Katalysator-Partikel

(fest)

bis ca. 70 bar

Kühlung

adiabate Festbett-

katalysatoren

Synthesegas

(CO, H2)

methanreiches Produktgas

Produktgas-rezirkulation

gestufte Edukt-zugabe

Zwischenkühlung

Zwischenkühlungca. 300-400°C

bis 600°C

gestufte Edukt-zugabe

Beispiel:

Synthane Hot Tube ReactorThermoöl-

Kühlung

Synthesegas

(CO, H2)

methanreiches Produktgas

ca. 400°C

adiabate Festbettreaktoren gekühlte Reaktoren Beispiel:

Synthane Hot Tube Reactor

Beispiel:

Lurgi Methanation

Beispiel:

Thyssen Comflux-Verfahren

Beispiel:

Chem Systems Liquid Phase Methanation

Flüssigphasen-Methanierung Wirbelschicht-Methanierung

syngas

raw-SNGheat exchanger

separatorreactants(gaseous)

inert fluid(liquid)

catalyst particles (solid)

three-phase fluidized bed

Three-phase methanation

e.g. Chem systems liquid phase methanation

3-Phasen-Wirbelschicht

Synthesegas

(CO, H2)

methanreiches Produktgas

Synthesegas/ Produktgas

(gasförmig)

Katalysator-Partikel

(fest)

ca. 70 bar

Zwischenkühlung

inertes Trägeröl

(flüssig)

Trägeröl-

Rezirkulation

Separatordruckaufgeladene Wirbelschicht

Synthesegas

(CO, H2)

methanreiches Produktgas

Synthesegas/ Produktgas

(gasförmig)

Katalysator-Partikel

(fest)

bis ca. 70 bar

Kühlung

adiabate Festbett-

katalysatoren

Synthesegas

(CO, H2)

methanreiches Produktgas

Produktgas-rezirkulation

gestufte Edukt-zugabe

Zwischenkühlung

Zwischenkühlungca. 300-400°C

bis 600°C

gestufte Edukt-zugabe

Beispiel:

Synthane Hot Tube ReactorThermoöl-

Kühlung

Synthesegas

(CO, H2)

methanreiches Produktgas

ca. 400°C

adiabate Festbettreaktoren gekühlte Reaktoren Beispiel:

Synthane Hot Tube Reactor

Beispiel:

Lurgi Methanation

Beispiel:

Thyssen Comflux-Verfahren

Beispiel:

Chem Systems Liquid Phase Methanation

Flüssigphasen-Methanierung Wirbelschicht-Methanierung

pressurized fluidized bedup to 70 bar

reactants (gaseous)

catalyst particles (solid)

syngas

raw-SNG

cooling

Fluidized bed methanation

e.g. Thyssengas Comflux process

State-of-the-Art

7

Since methanation is highly exothermic, the thermodynamic equilibrium demands low temperatures

and high pressures for a maximum methane yield. In the majority of processes demonstrated, nickel-

based catalysts were used. The main issue with these is the removal of the heat of reaction that is

released, with the aim of achieving the appropriate gas properties and preventing the destruction of

the catalyst.

Methanation with adiabatic fixed bed reactors

Methanation with adiabatic fixed bed reactors is the state-of-the-art concept for the production of

SNG. The common feature of all concepts with adiabatic fixed bed reactors is that they exist of two

to six reactors with intermediate cooling and recycle of the product gas or staged injection of feed.

The methanation concept with probably the highest amount of SNG output to date is the Lurgi

methanation process [17]. It consists of three reactors with intermediate cooling and a recycle of

product gas of around 70-85 % from the outlet of the second stage to the first one. A bypass of the

first reactor enables a staged feed injection of 10-60 % into the second reactor. The outlet gas from

the first reactor has typically a temperature of around 650°C and a CH4 content of 60-70 vol. %. In the

final stage the outlet gas temperature is around 290-400°C and the CH4 content between

85-95 vol. %. BASF is the exclusive supplier of the catalysts (e.g. BASF G1 85) used in the Lurgi

methanation process, which was first demonstrated in two semi-commercial pilot plants in South

Africa (for SASOL) and in the petroleum refinery Schwechat in Austria [18]. The DGC Great Plains

synfuels plant, which was the first – and for a long time only - large-scale commercial SNG plant, is

also based on the Lurgi methanation process [3].

Another important fixed bed methanation process is the Haldor Topsøe TREMP process [19], which is

quite similar to the Lurgi methanation, but tries to minimize the recycle ratio. This is possible due to

the usage of high temperature methanation catalysts (Topsøe MCR), which resist temperatures up to

700°C. The high process temperatures allow the efficient usage of waste heat by production of

superheated steam with typically 540°C at 100 bars. The TREMP process originates from the first

ADAM and EVA project [20]. The idea was to use chemically bound energy for long-distance

transportation of nuclear energy. A high temperature nuclear reactor provides the heat for the

reformation of methane (EVA). The produced syngas can be transported via pipelines to the

methanation plant (ADAM). The methanation plant re-converts the syngas to methane by release of

high temperature process heat. For a high efficiency, high process heat temperatures and therefore a

high temperature methanation process, TREMP, is required. The second-largest SNG plant in the

world, located in Yining in the province of Xinjiang and operated by the Chinese Qinghua Group, uses

the TREMP process for the production of SNG from coal [21]. In addition, several other large-scale

coal-to-SNG projects in China and Korea as well as the largest biomass-to-SNG project (GoBiGas)

intend to use the TREMP technology for methanation [21].

Besides the two most common processes, pilots of several other methanation concepts with fixed

bed reactors have been developed and demonstrated, such as the Conoco/Westfield process [22],

IGT Hygas process [23], RMP process [24], and the HICOM process [4].

State-of-the-Art

8

Methanation with cooled reactors

The main idea of cooled reactor concepts is a reduction of process complexity by reducing the

amount of reactors to, ideally, a single reactor. The challenge for cooled reactor concepts is the

removal of exothermic heat of the methanation process. In fixed bed reactors this heat removal is

limited by the high thermal resistance of the bed. Therefore, classical fixed bed concepts are not

suitable.

One approach is the usage of catalytically coated heat transfer elements, as demonstrated within the

Synthane hot-gas recycle (HGR) and tube-wall reactor (TWR) [25]. The TWR reactor consists of tubes

which are coated with Raney nickel on their inside. A heat transfer fluid removes the heat of reaction

and keeps the reaction temperature below 390°C.

Another idea was to also use the Linde isothermal reactor for methanation [4]. The Linde isothermal

reactor is a fixed bed reactor with a large number of cooling tube bundles in the catalyst bed.

However, there are no reports of its actual use for large-scale methanation.

A newer concept, which might allow nearly isothermal operation, bases on honeycomb catalysts.

Catalytically coated honeycomb carriers are easier to equip with heat transfer elements. Within the

RFCS research project ‘CO2freeSNG’, the usage of honeycomb methanation catalysts has been

investigated [26].

Three-phase methanation

Another option for isothermal methanation is the three-phase, or liquid-phase, reactor, in which a

bubble column-like reactor contains an inert heat transfer fluid and a solid catalyst. The gas passing

through the reactor fluidizes the catalyst, thus creating a three-phase fluidized bed.

Such a concept was demonstrated by Chem Systems [27] within their liquid-phase methanation/shift

process. The operating pressure was up to 70 bars. Mineral oil was used as a heat carrier and nickel

containing balls as a catalyst.

Nowadays, the usage of liquid-phase methanation is investigated for methanation of hydrogen and

carbon dioxide for power-to-gas production [28]. The advantage of the liquid-phase methanation is

the higher degree of flexibility offered during dynamical operation, as the fluid is easier to keep on

temperature.

Fluidized bed methanation

Fluidized bed methanation allows a simpler removal of exothermic heat from the reactor and

therefore a nearly isothermal operation. Furthermore, the catalyst can be replaced or partially

replaced more easily also during operation.

The Bi-Gas project [29] of Bituminous Coal Research Inc. demonstrated the methanation of coal-

derived syngas in a fluidized bed with a diameter of 150 mm and a reaction zone length of 2.4 m.

Around 3 m² of finned cooling tubes, cooled with a heat transfer fluid, remove the heat from the

reactor. The main challenge with fluidized bed methanation is the attrition of the catalyst. Since

according to reports, the number of fine particles increases during operation whereas the number of

coarse particles decreases. Attrition-stable catalysts are required for fluidized-bed methanation.

The largest demonstration plant for fluidized bed methanation was the Comflux process built by

Thyssengas [30]. The pre-commercial plant had a power of up to 20 MWSNG. One special feature of

this plant was the combination of methanation and water-gas shift within the same reactor.

The Paul-Scherrer-Institute (PSI) and partners developed a 1 MWSNG demonstration project for

methanation of biomass-derived synthesis gas at the FICFB gasification plant in Güssing

(chapter 2.2.2) [4].

State-of-the-Art

9

2.2. Large SNG plants and projects in operation

After the energy crises of the 1970s had been overcome, gas prices remained at a level with which

SNG from coal could not compete. Therefore, the majority of SNG research and demonstration

projects were stopped in the 1980s. Bucking this general trend, the DGC Great Plains synfuels plant,

which until 2013 remained the only large-scale SNG plant, started its operation in 1984.

With ever-increasing energy demand of countries like China or India, several new coal-to-SNG plants

are now being planned and constructed; the first large-scale plant in China, in the Inner Mongolia

region started to operate in 2012. In the last few years, with the favoring of renewable sources of

energy in Europe, SNG production from biomass has become an interesting option, as demonstrated

in the 1 MWSNG biomass-to-SNG/CNG project developed by PSI for the Güssing gasification plant. The

largest project currently under commissioning (Jan. 2014) is the GoBiGas project in Goteborg with a

total SNG capacity of 20 MW.

2.2.1. Large-scale coal-to-SNG plants

DGC Great Plains synfuels plant

The Dakota Gasification Company´s (DGC) Great Plains synfuels plant in North Dakota [3] was the

first large-scale commercial plant for the production of SNG from coal. Its 14 Lurgi-Mark-IV gasifiers

convert around 18,000 tons of coal per day. After gasification, around 2/3 of the gas is cooled and

removed from condensed water (figure 2.3). As the condensed process water contains valuable

by-products, separate by-product processing extracts phenol, dephenolized cresylic acid and

ammonium sulfate. The remaining 1/3 of the gas passes a shift conversion unit until it reunites with

the cooled gas stream. A Rectisol scrubber then removes contaminations and CO2 from the syngas.

Since 1999 the compressed CO2 has been fed into a pipeline and transported to oilfields for enhanced

oil recovery. Having passed the Rectisol unit, the cleaned synthesis gas is converted to SNG by a Lurgi

fixed bed methanation process. Before feed-in into the gas grid, water is removed and the dry SNG is

compressed to pipeline pressure. The average amount of SNG produced every day is around

4.33 mil. m³ with a heating value of 36.3 MJ/m³ and a corresponding SNG power of 1.82 GW [31].

To increase the income an ammonia plant was added which uses a slipstream of the synthesis gas. In

2012 the revenue from sales of SNG was $ 252.4 million and of by-and co-products at $ 295.3 million

[31]. The fact, that more than the half of the revenue comes from the selling of by-products, shows

how important the efficient usage of by-products is for large-scale plants.

Figure 2.3: Simplified flow sheet of the DGC Great Plains synfuels plant, adapted from [3]

ASUAir

Ash lock

Lurgi gasifiers

Coal lock

Coal Gas cooling

Shift conversion

Rectisol unit

Fixed bed methanation

Gravity separation

Tar oil By-product processing

Phenol, Cresol, Ammonium sulfate

SNG

CO2 for enhanced oil recoveryN2, Xe,

KrAsh

Steam

Naphta

Condenser

Water

Syngas to ammonia plant

O2

State-of-the-Art

10

Datang Keshiketeng (Hexigten) SNG plant

China`s first SNG plant, the Datang Keshiketeng SNG plant [32], started its operation in September

2012. It is located in Keshiketeng (Hexigten) in the Inner Mongolia region. The first phase has a plant

capacity of 1.33 bn. Nm³ SNG per year (around 1.4-1.6 GWSNG). It is planned to add two plants of the

same size in phases two and three after successful operation of phase one. The gasification

technology is provided by SEDIN (Second Design Institute of Chemical Industry) [33]. The plant uses

an SNG process (fixed bed) from Davy Process Technology with purification and methanation

catalysts from Johnson Matthey.

Yining SNG plant

The second large-scale SNG plant in China, operated by the Chinese Qinghua (Kingho) Group and

located in Yining/Yili in the province of Xinjiang, started its operation in 2013 [21]. Its planned SNG

output of the first phase is around 1.4 bn. Nm³ per year, which is equivalent to an SNG power of

1.5-1.7 GW, depending on the heating value of the gas. The final phase will have an SNG output of

around 5.5 bn. Nm³ per year. The majority of the produced SNG will be fed into a pipeline and

transported to the more densely populated eastern part of China. The plant uses the Haldor Topsøe

TREMP technology for methanation of the coal-derived synthesis gas. SEDIN provides the sixteen

gasifiers [33].

2.2.2. Biomass-to-SNG projects

Güssing/PSI

The fast internally circulating fluidized bed (FICFB) gasifier [34] installed in Güssing, Austria, which

was developed at Vienna University of Technology and constructed by Repotec, has operated

commercially since 2002. The main purpose of the Güssing gasifier is combined heat and power

generation (CHP). The total fuel capacity is 8 MW (wood chips) and the electrical output around

2 MW. The FICFB gasifier consists of two zones, a gasification zone and a combustion zone. In the

combustion zone, bed material (olivine) is heated up by combustion of biomass with air. The hot bed

material circulates to the gasification zone, where it provides the heat for the endothermic

gasification of biomass by means of water steam. This allows the production of synthesis/producer

gas, which contains next-to no nitrogen. Table 2.1 shows the typical gas compositions for the Güssing

gasification plant.

Table 2.1: Typical gas compositions of the FICFB gasifier, operated with wood chips, according to [35]

Permanent gases

H2 CO CO2 CH4 N2 35-45 vol. % 19-23 vol. % 20-25 vol. % 9-11 vol. % ≈1 vol. %

Higher hydrocarbons

C2H4 C2H6 C3H8 BTX Tars 2-3 vol. % ≈0.5 vol. % ≈0.5 vol. % 10 g/Nm³ 1-5 g/Nm³

Contaminations

H2S COS org. S HCl NH3 ≈150 ppm ≈5 ppm ≈37 ppm ≈3 ppm 500-1500 ppm

State-of-the-Art

11

The favorable gas compositions and the high availability were the reasons for demonstrating SNG

production from biomass on a slipstream of the FICFB gasifier. After bench-scale tests, the Paul-

Scherrer-Institute (PSI), in cooperation with Conzepte Technik Umwelt AG (CTU) and Repotec,

developed and constructed the whole process chain for a 1 MWSNG demonstration [36].

After gasification, particles are removed and the gas passes an RME scrubber (figure 2.4). The

majority of the gas goes to a gas engine. A slipstream is further processed for the SNG production.

Before methanation, the gas is compressed and cleaned of H2S. The methanation takes place in a

fluidized bed reactor, adapted from the Comflux process [4]. To meet the specifications for further

applications, NH3, H2O, CO2 and H2 are removed step by step from the raw-SNG.

Figure 2.4: Simplified flow sheet of SNG production in the FICFB gasification plant, adapted from [4]

The main challenge for methanation is the high ethylene concentration in the synthesis gas and the

resulting coking of the catalyst. Kopyscinski [37], [38] reported that the advantage of fluidized bed

methanation is the internal regeneration of the catalyst. Measurements showed strong carbon

exchange processes between gas phase and carbon species on the catalyst surface. The gas

compositions change over the height of the fluidized bed. Therefore the atmosphere of the upper

part of the fluidized bed allows a removal of deposited carbon from the catalyst.

GoBiGas

The largest European biomass-to-SNG project under commissioning (Jan. 2014) is the Gothenburg

Biomass Gasification (GoBiGas) project [39]. It will demonstrate the commercial production of SNG

from biomass with an SNG power of 20 MW. The gasifier used in Gothenburg is based on the FICFB

technology and is being constructed by Metso under a Repotec license. As in the plant in Güssing, the

first gas cleaning steps are the removal of dust trough textile filters and the removal of tars and other

solvable pollutants in an oil scrubber. Before methanation, the gas is compressed and passes a sulfur

removal unit, a water-gas-shift unit and a CO2 removal unit. For methanation, the Haldor Topsøe

TREMP process was chosen. After cooling and drying, the produced SNG is fed into the Swedish gas

grid.

The results of the first GoBiGas project should constitute the basis for a 100 MW follow-up project.

Ash

Filter Fluidized bed methanation

FICFBgasifier

RME

RME scrubber

Bulk H2S removal

Pre-heating

Biomass

Air

Steam Tars/tiophene

Fine H2S removalFlue

gas

NH3/H2O removal

CO2/H2 removal

SNG

CO2

H2Water

To gas engine

State-of-the-Art

12

Heatpipe-Reformer

The Heatpipe-Reformer (HPR) [6], which was developed at the University of Technology Munich

consists of two separated fluidized beds, one for combustion and one for gasification (figure 2.5 a).

The heat required for endothermic gasification is transported from the combustion chamber to the

reformer by means of heat pipes. These are closed tubes, filled with a small amount of sodium or

potassium. Due to the evaporation and condensation of the fluid, high heat fluxes can be achieved.

The reformer is pressurized during operation and uses water steam for fluidization and gasification.

Two prototypes were erected and tested under the European ‘Biomass Heat Pipe Reformer’ project

[40]. Pilot plants with a thermal input of 500 kW were developed by Agnion Energy Inc. in

Pfaffenhofen [7] and by HS Energieanlagen GmbH in Freising (both in Germany). Agnion erected the

first commercial plant with a thermal input of 1.3 MW in Grassau, Germany in 2012. In it, the syngas

produced fuels a gas engine for CHP.

As the gas quality achieved there is similar to that of the Güssing gasifier, the HPR is ideal for

synthesis applications. One of the possible applications of the HPR is the decentralized production of

SNG from biomass [41] (figure 2.5 b), the idea being that of using small-scale units to generate SNG

in rural areas, close to where the biomass resources are. The existing gas infrastructure allows the

transporting of the bio-SNG to areas with a higher demand. The waste heat from the process can be

used in local heat grids. However, small-scale units require lower complexities, as an economical

operation using the demonstrated state-of-the-art process chains for SNG production is not possible.

The European research project ‘CO2freeSNG’ investigated an upscale of the HPR technology for the

production of SNG from coal and lignite [26]. Besides an experimental validation, concept studies for

SNG production in a 50 MW range were developed.

Figure 2.5: a. Conceptual design of the HPR, b. idea for decentralized SNG production, according to [41]

FuelSteamSyngas

Flue gas

Combustion chamber

Reformer

Heat pipes

State-of-the-Art

13

2.2.3. Future large SNG plants and projects

In the last few years, plans for constructing a number of large-scale coal-to-SNG plants have been

announced. SNG from coal is attractive for countries with substantial domestic coal resources but

little natural gas. New projects are therefore mainly being considered in countries that are highly

dependent on imports of natural gas, such as China and South Korea. With the increasing gas prices

from 2000 to 2008, interest for new coal-to-SNG projects also began to grow in the United States.

Some of the projects were already quite specific, until sharply dropping gas prices stopped all

activities. Different press releases also mentioned plans for SNG plants in the Ukraine [42] and

Indonesia [43].

Currently (December 2013), concrete activities for erection of further large-scale coal-to-SNG plants

can be found only in Korea and China [33].

Numerous different technologies are planned or proposed for the different SNG projects. Table 2.2

gives an overview of the different gasification systems proposed for specific SNG projects.

Table 2.2: Overview of gasification systems proposed for specific SNG projects, adapted from [33]

Name Type Project

Siemens [44] entrained flow CPI Yinin (CN), Decatur SNG plant (US) SES U-Gas fluidized bed Jiangxi SNG (CN) [45] CB&I E-Gas entrained flow Posco Gwangyang (KR) GreatPointEnergy Bluegas hydromethanation Wanxiang Turpan (CN) [46] TPRI gasification entrained flow CHNG Xinjiang (CN) SEDIN fixed bed ? Datang Keshiketeng (CN), Yining SNG (CN)

For methanation, mainly systems from Haldor Topsøe, Davy - Johnson Matthey and Foster Wheeler -

Clariant are proposed. All these systems base on fixed bed methanation.

Posco Gwangyang SNG, Korea

The first South Korean large-scale coal-to-SNG plant is currently under construction in Gwangyang.

The start-up is estimated for 2014 and SNG production output is expected to be 500,000 t per year.

This equals an SNG power of around 550-700 MW, depending on the heating value of the SNG. Three

ConocoPhillips (CB&I) E-gas gasifiers (one back up) will produce the synthesis gas. The gas will be

cleaned by means of a Rectisol unit delivered by Linde. The plant will use the Haldor Topsøe TREMP

technology for the methanation of the synthesis gas. [47]

CPI Yinin, China

The China Power Investment Corporation (CPI) is planning to erect a 2 billion Nm³/year

(1.9-2.2 GWSNG) coal-to-SNG plant in Yinin/Yili in Xinjiang province. Siemens will deliver eight Siemens

SGF-500 entrained flow gasifiers with a thermal power of 500 MW each, while Haldor Topsøe will

supply the methanation. [48]

Other Chinese SNG projects

Besides the already constructed Datang and Yining SNG plant and the CPI Yinin plant, six other coal-

to-SNG plants have been approved by the Chinese government [49]. The total SNG capacity of the

approved SNG plants is 37.1 bn. Nm³ per year [49], which is equivalent to an SNG power of around

40-45 GW. However, only little information on the project and construction progress is available.

Theoretical Background

15

Chapter 3

3. Theoretical Background