GEH-7282

-

Upload

alexwongks6118 -

Category

Documents

-

view

213 -

download

0

Transcript of GEH-7282

-

7/28/2019 GEH-7282

1/55

GEH-7282

g kV/kV2 MODBUS Communications OptionInstruction Manual

-

7/28/2019 GEH-7282

2/55

Notice:

The information contained in this document is subject to change without notice.

GE makes no warranty of any kind with regard to this material, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. GE shall not be liable for errors

contained herein or incidental consequential damages in connection with the furnishing, performance, or

use of this material.

This document contains proprietary information, which is protected by copyright. All rights are reserved.

No part of this document may be photocopied or otherwise reproduced without consent of GE.

Copyright (c) 2002 by GE

Published in a limited copyright sense. All rights, including trade secrets, are reserved.

Document Edition - First 3/2002

kV, kV2, MeterMate, and OPTOCOM are trademarks of GE.

MS-DOS and Windows are trademarks of Microsoft Corporation.

FCC Notice

FCC Part 15: Preventing Radio and Television Interference

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesirable

operation.

Changes or modifications to this equipment not expressly approved by the General Electric Company could

void the users authority to operate this equipment.

This instruction book does not cover all details or variations in equipment nor provide for every possiblecontingency to be met in connection with installation, operation, or maintenance. The equipment covered

by these instructions should be operated and serviced only by competent technicians familiar with good

safety practices, and these instructions are written for such personnel and are not intended as a substitute

for adequate training and experience in safe procedures for this type of equipment. Should further

information be desired, or should particular problems arise which are not covered sufficiently for the

purchasers purpose, the matter should be referred to GE Meter.

Warning

Any work on or near energized meters, meter sockets, or other metering equipment can present a

danger of electrical shock. All work should be performed only by qualified industrial electricians and

metering specialists in accordance with local utility safety practices and the procedures outlined in

the Handbook for Electricity Metering, Chapter 14 (available from Edison Electric Institute, 111119th Street NW, Washington, DC 20036). The information contained in this instruction book is

intended to be an aid to qualified metering personnel. It is not intended to replace the extensive

training necessary to install or remove meters from service.

Related Publications:

GEH-5081 GE kV Vector Electricity Meter Installation, Operation, and Maintenance Guide

Page 1 of 55

-

7/28/2019 GEH-7282

3/55

GEH-7277 GE kV2 Multi-Function Meter Product Description, Operating Instructions,

Maintenance Instructions, Upgrading, Site Analysis Guides, Diagrams

GEH-5084 MeterMate for DOS

Reading and Programming Software for GE Electronic Meters

GEH-5082 MeterMate for Windows

Program Creation Software for GE Electronic Meters

Page 2 of 55

-

7/28/2019 GEH-7282

4/55

Table of Contents

INTRODUCTION 5

KV/KV2 MODBUS FEATURES 5MODBUS Device Address 5Data Rate 5

INSTALLING THE KV/KV2 MODBUS IN THE KV OR KV2 METER 5

kV/kV2 MODBUS Installation 5

Installation on S-base Meters 6

Installation on A-base Meters 8

Option Board Compatibility 8

Introduction 8Revenue Guard Option Board 9I/O-1 Input/Output Option Board (Obsolete) 9I/O-2 Input/Output Option 9LP-1 Load Profile Option Board (Obsolete) 9LP-2 Load Profile Option Board 9kV/kV2 MODBUS Option Board 10

MeterMate Software Compatibility 10METER INSTALLATION 10

RENEWAL PARTS 11

kV/kV2 MODBUS Kits 11S-Base kV/kV2 MODBUS Kits 11A-base kV/kV2 MODBUS Kits 11

Other Renewal Parts: 12

APPENDIX A MODBUS OPERATION 13

Commands Supported 13

Password and Data Access 13

MODBUS Address 13

Accessing the Data Log 13

APPENDIX B REGISTER MAPS 15

kV Register Map: 15

Page 3 of 55

-

7/28/2019 GEH-7282

5/55

kV2 Register Map: 28

APPENDIX C - REPLACING THE CABLE CONNECTOR 43

APPENDIX D 44

Network Architecture and Wiring 44Modbus Wiring Rules Diagrams 44

Network Wiring and Construction 48

Wiring Requirements 49Type of Wire 49Termination 49Shield Grounding 49

Local Configuration of IEDs 50

Applying Power to the System 50

Trouble-Shooting Guide 51

APPENDIX E - METER PROGRAMMING PARAMETERS 52

Required Programming Parameters 52KV Meter 52KV2 Meter 52

Page 4 of 55

-

7/28/2019 GEH-7282

6/55

Introduction

The kV/kV2 MODBUS Communications Board

is an optional factory-supplied addition to the

kV or kV2Meter, or may be ordered in theform of a retrofit kit to upgrade Communication

Ready kV Meters or kV2 Meters. KV

Meters that are capable of being upgraded may be

identified by the words Modem Ready on theupper nameplate of the meter.

The kV/kV2 MODBUS Option Board is used toprovide two-way communication to the kV or

kV2 Meter and may be used on S-base, A-

base, and switchboard meters. It is available only

on Demand/LP or TOU version of the kV orkV2 Meter.

The kV/kV2 MODBUS Option Board may be

used in conjunction with other GE option boards,

which provide a three-phase power supply, loadprofile recording (kV only), and input/output

functions. If required, the flexibility of the kV

and kV2 Meters makes it possible to combineup to 3 option boards in a single meter.

RS-485/MODBUS provides a half-duplex, 2 -

wire, RS-485 interface for remote reading of the

kV/kV2 Meter. The baud rate is fixed at 19200

bps.

All kV Meters, including those with kV/kV2

MODBUS boards, are programmed using GEsMeterMate software program.

kV/kV2 MODBUSFeatures

The kV/kV2 MODBUS Option Board provides a

means of remotely reading the kV/kV2 Meter

over an electrically isolated, twisted pair, half-

duplex, RS-485 link. The kV/kV2 MODBUScontains only two programmable features,

discussed in more detail below.

MODBUS Device Address

The MODBUS board is delivered with a default

address of 15 (0x0F). Prior to installation into asystem, each device must be programmed with a

unique address. Refer to Appendix A, Register

Maps for the appropriate register address.

The MODBUS board must be programmed with a

password that matches that of the meter on whichit is installed. All MODBUS boards have a

default password of MASTER_012. It is

recommended that this same password beprogrammed into the meter on which the board is

installed. If a different password is desired, the

meter must be programmed with the desired

password using MeterMate software. TheMODBUS board must be set with the desired

password using the MODBUS interface. Refer to

Appendix A, Register Maps, for the appropriate

register address.

Data Rate

The kV/kV2 MODBUS Option is configured for

8 data bits, 1 stop bit, no parity, and a fixed baud

rate of 19200bps.

Installing the kV/kV2MODBUS in the kV orkV2 Meter

Warning: The kV/kV2 Metercontains lethal voltages. The meter must

be completely disconnected from any

external circuits and the carryovercapacitor completely discharged before

disassembly is attempted. Failure to

observe this practice can result inserious injury or death. For more

information refer to the appropriate

meter instruction book.

kV/kV2 MODBUS Installation

The kV/kV2 MODBUS Option Board can only be

installed in Modem Ready kV Meters. Thesemeters can be identified by the words Modem

Ready which are printed on the left side of the

meter nameplate. All kV2 meters are modemready.

Any combination of up to three (3) option boards

may be installed in the kV/ kV2 Meter at one

time. These include the I/O-2 Input/Output optionboard, the MIO Multi-Input/Output option board

Page 5

-

7/28/2019 GEH-7282

7/55

(kV2 only), the LP-2 Load Profile option board

(kV only), the kV/kV2 MODBUS Option Board,

and the RG-1 Revenue Guard option board. The

I/O-2 (or MIO), LP-2, and kV/kV2 MODBUS

Option Board can be combined in an option boardstack if necessary. See Figure 1 for details.

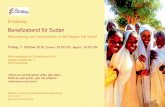

Figure 1: Option board stack

The Revenue Guard option board is not part of

this stack and is not affected by the presence of

other option boards.

All MODBUS boards are shipped with an RJ-11

cable connector. This connector will typically

need to be removed and replaced with a connectorappropriate for the network in which the

MODBUS meter will be installed. Appendix C

contains a wiring diagram to facilitate thisprocedure.

The kV/kV2 MODBUS board is installed asfollows:

1. If the meter is not disassembled, follow the

disassembly instructions described in the

appropriate meter instruction book.

2. Place the bezel face down on a soft, cleansurface to protect the nameplate and liquid

crystal display.

3. Remove the I/O (or MIO) and LP option

boards if they are present.

4. The I/O-1 and LP-1 option boards must notbe reused with the kV/kV2 MODBUS

board.

5. If the kV/kV2 MODBUS Option Board will

not be combined with either the I/O or LP

option boards proceed to step 9. If the

kV/kV2 MODBUS Option Board will be

installed with the I/O-2 and/or LP-2 option

boards proceed to the next step.

6. Place the kV/kV2 MODBUS Option Boardon a soft clean surface and install the four

(4) nylon spacers by gently pushing theminto the four (4) holes on the board.

Do not reuse nylon spacers. When

removed, a slight rounding of the spacer

occurs which can greatly decrease the

ability of the spacer to hold the option

board firmly in place.

7. If both the LP-2 and I/0-2 option boards areto be installed, the LP-2 option board must

be installed next. Install it by engaging the

26 pin connector pins between the kV/kV2

MODBUS Option Board and the LP-2

option board. Then, after lining up the nylonspacers on the kV/kV2 MODBUS Option

Board with the four (4) holes on the LP-2

board, snap the option board into place.

8. The I/O-2 option board may be installed

directly to the kV/kV2 MODBUS Option

Board if the LP-2 option board will not be

used or, it may be installed directly to the

LP-2 option board. Either way, the I/O-2

option board is installed in a similar mannerto the LP-2 option board described in step 6

above.

Note: The kV/kV2 MODBUS Option Boardmust always be installed as the inner mostoption board (the board closest to theMeters main board).

9. Depending on whether the installation isbeing made to an S-base or A-base meter,

install the appropriate cable assembly as

described below. For installation on a

switchboard kV/kV2 Meter, refer to the

switchboard meter instruction book, GEH-7271.

Installation on S-base Meters

While the meter is unassembled, the S-basecommunications cable assembly must be

installed. This cable assembly is installed in S-

base meters as follows:

1. With the kV Meter base facing you, locate

the lower of the two small knockouts andremove it (see Figure 6: Locating knockout

for cable assembly on S-Base meters).

Enlarge the hole to a diameter of 0.290inches. Make sure the resulting hole is

clean.

Page 6

-

7/28/2019 GEH-7282

8/55

2. Locate the end of the cable assembly with

the two small black connectors. Pass the

larger of the black connectors through the

knockout hole from the back side of the

meter base. Next, pass the smaller blackconnector through the same hole and pull

until the wire tie is in the slot and up against

the base. Make sure that the cable has beenbrought up on the outside of the shroud.

Figure 6: Locating knockout for cableassembly on S-Base meters

3. Check the headers on the kV/kV2MODBUS board to make sure that the pins

are not bent or out of position. Orient the

smallest black connector such that the

indexed (filled) hole in the black connectoris lined up with the missing pin in the 4 pin

header. Plug the connector assembly into

the header on the MODBUS board. Orient

the larger black connector such that theindexed (filled) hole in the black connector

is lined up with the missing pin in the 6 pin

header. Plug the connector assembly intothe header on the MODBUS board.

4. Attach the plastic connector holder as shownin Figure 7. The connector holder snaps

should extend through the holes in the

kV/kV2 MODBUS board and snap intoplace.

5. Check the 30 pin header on the meter board

to make sure that the pins are not bent or out

of position. Adjust any pins that are out of

alignment.

kV Meters with 26 pin headersinstead of 30 pin headers cannot be

retrofitted with the kV/kV2 MODBUSOption Board .

Figure 7 : Connector holder placement

6. With the kV/kV2 MODBUS Option Board

stack in hand, insert the tabs on thekV/kV2 MODBUS Option Board into theslots in the bezel (see figure 8).

Figure 8: Inserting option boards

7. Gently lower the board until the 30 pin

connector on the meter and the kV/kV2

MODBUS Option Board are engaged. Makesure that the two snaps engage the board.

8. Reassemble the meter, except for the cover,as described in the kV or kV2 Meter

instruction book. Insert and tighten a wire tiearound the cable assembly on the inside of

the meter base to retain the cable assembly.

9. Place the special label indicating the presence

of MODBUS communications on the side of

the meter shroud and replace the cover. SeeFigure .

Page 7

-

7/28/2019 GEH-7282

9/55

Figure 9 : Check "RS" box

Installation on A-base Meters

While the meter is unassembled, the A-basecommunications cable assembly must be

installed. This cable assembly is installed in A-

base meters as follows:

1. With the Meter base facing you, locate the

knockout on the left side of the base (see

Figure 10) and remove it by tapping it with apunch. Make sure the hole is clean and the

knockout parts are removed.

Figure 10: Locating knockout for cableassembly on A-Base meters

2. Insert the small connectors end of the cableassembly through the knockout from theoutside of the meter base until the grommet

contacts the knockout. Make sure that the

cable has been brought up on the outside ofthe shroud.

3. Insert the grommet into the knockout and

push until the grommet is fully seated.

4. Check the headers on the kV/kV2

MODBUS board to make sure that the pins

are not bent or out of position. Orient the

smallest black connector such that the

indexed (filled) hole in the black connectoris lined up with the missing pin in the 4 pin

header. Plug the connector assembly into

the header on the MODBUS board. Orientthe larger black connector such that the

indexed (filled) hole in the black connector

is lined up with the missing pin in the 6 pin

header. Plug the connector assembly intothe header on the MODBUS board.

5. Attach the plastic connector holder as shown

in Figure 7. The connector holder snaps

should extend through the holes in thekV/kV2 MODBUS board and snap into

place.

6. Follow the steps outlined in the S base

installation for inserting the stack into themeter. Then, reassemble the meter.

7. Place the special label indicating thepresence of MODBUS communications on

the side of the meter shroud and replace the

cover. See Figure .

Option Board Compatibility

Introduction

The kV/kV2 MODBUS Option Board may

be used in conjunction with the RG-1 Revenue

Guard, I/O-2 Input/Output, and the LP-2 LoadProfile option boards. In cannot be used with

either the I/O-1 Input/Output, the LP-1 Load

Profile option boards or the kV/kV2 Internalmodem board. The MODBUS is used in lieu of

the kV/kV2 Internal Modem board.

The kV/kV2 MODBUS Option Board is

always installed directly onto the kV/kV2Meter. Either the I/O-2 Input/Output or the LP-2

Load Profile option board may then connect tothe kV/kV2 MODBUS Option Board ifdesired. If all three option boards are used, the

option boards must be installed in the following

order:

1. kV/kV2 MODBUS Option Board

2. LP-2 Load Profile option board (kV only)

3. I/O-2 Input/Output option board (or MIO

board (kV2 only)

Page 8

-

7/28/2019 GEH-7282

10/55

Revenue Guard Option Board

The Revenue Guard option board may be used in

conjunction with any other kV/kV2 Meter

option board including the kV/kV2MODBUS Option Board.

I/O-1 Input/Output Option Board(Obsolete)

The I/O-1 Input/Output option board (GE part #

9938226002) is now obsolete and has been

replaced by the I/O-2 Input/Output option board

(GE part # 9938226004). The I/O-1 option board

cannot be used with the kV/kV2 MODBUSOption Board. If I/O is needed in a kV Meter

with a modem, the I/O-2 option board must be

used. For the kV2 either the I/O-2 or the MIOInput/Output option can be used. See Table 1:I/O-1 Compatibility for more details.

I/O-1 LP-1 LP-2 kV/kV2

MODBUS

Table 1: I/O-1 Compatibi lity

I/O-2 Input/Output Option

The I/O-2 Input/Output option board (GE part #

9938226004) is a direct replacement for the I/O-1

option board (see above) and was designed to becompatible with the kV/kV2 MODBUS Option

Board. It may be installed directly onto the

kV/kV2 Meter, the kV/kV2 MODBUSOption Board, or to the LP-2, Load Profile option

board. See Table 2: I/O-2 Compatibility for more

details.

Option Boards

I/O-2 LP-1

(kV only)

LP-2

(kV only)

kV/kV2

MODBUS

Modem ReadykV only Modem ReadykV only

Table 2: I/O-2 Compatibi lity

LP-1 Load Profile Option Board(Obsolete)

The LP-1 Load Profile option board (GE part #

9938348005) is now obsolete and has been

replaced by the LP-2 Load Profile option board

(GE part # 9938348007). The LP-1 option boardcannot be used with the kV/kV2 MODBUS

Option Board. For use with the kV/kV2MODBUS board in a kV Meter, the LP-2

option board must be used. See Table 3: LP-1

Compatibility for more details.

Option Boards

LP-1

(kV only)

I/O-1

(kV only)

I/O-2 kV/kV2

MODBUS

Table 3: LP-1 Compatibi lity

LP-2 Load Profile Option Board

The LP-2 Load Profile option board (GE part #

9938348007) is a direct replacement for the LP-1

option board (see above) and was designed to be

compatible with the kV/kV2 MODBUS OptionBoard. It may be installed directly onto the kV

Meter or the kV/kV2 MODBUS Option Board.

See Table 4: LP-2 Compatibility for more details.

Page 9

-

7/28/2019 GEH-7282

11/55

Option Boards

LP-2

(kV only)

I/O-1

(kV only)

I/O-2 kV/kV2

MODBUS

Modem ReadykV only Modem ReadykV only

Table 4: LP-2 Compatibil ity

kV/kV2 MODBUS Option Board

The kV/kV2 MODBUS Option Board may be

used in combination with the I/O-2 Input/Output,

and LP-2 Load Profile option boards. See Table5: kV/kV2 MODBUS Compatibility for more

details.

Option Boards

KV/KV2 MODBUS

Modem Ready kV

Or kV2

I/O-2

(or MIO

for kV2)

LP-2

(kV only)

Table 5: kV/kV2 MODBUS Compatibil ity

MeterMate SoftwareCompatibility

The kV/kV2 MODBUS Option Board iscompatible with the following software:

MeterMate Version 2.12 or greater. Note that

this software will ignore the MODBUS board.

There are restrictions on the way a kV/kV2 meter

must be programmed in order to operate correctly

with the MODBUS board. See Appendix C for

details.

Meter Installation

The kV/kV2 Meter must be connected to theexternal communications device through a means

which will provide both a secure connection and

ease of disconnection for troubleshooting, meter

change out, etc.

All kV/kV2 Meters with kV/kV2 MODBUS

option are supplied with an insulatedcommunications cable which extends

approximately 30 inches out the base on S-base

meters and out of the side of the case on A-basemeters. The communications cable will be

terminated in an RJ-11, which may be replaced by

the required connector following the wiring

diagram shown in Appendix B.

The communications cable should exit the S-base

meter socket enclosure by the most direct means

and be connected to the customer providedcommunications equipment external to the meter

enclosure. Usual practice has a short conduit

nipple extending from the meter enclosure to aseparate, dedicated enclosure where the external

modem is located.

Important: Under no condition should

the communications line be run in a conduit

with power lines or exit the meter enclosure

via the same nipple as the power lines. Also,

for the case where other optional signal lines

are taken from the kV/kV2 Meter, these

other lines should not be bundled with either

the power lines or the phone line.

For A-base meters, the connection to the

customer supplied communications equipmentshould be done in a similar manner. The

communications cable for the A-base terminalblock should be taken immediately to a separate

enclosure dedicated to this specific application.

Page 10

-

7/28/2019 GEH-7282

12/55

Figure 14: kV/kV2 MODBUS LED location

An LED will illuminate when the kV/kV2Meters MODBUS board is powered up. The

LED will flash for approximately 15 seconds.During this period, communications is not

possible. Immediately after the LED stops

flashing, the meter display should briefly indicate

busy as the MODBUS board reads basic

information from the meter. The LED will alsolight each time the MODBUS board has

established communications with the meter for

the purposes of acquiring data. By monitoring thisLED (as well as any LEDs on the external

modem), correct operation of the kV/kV2

MODBUS board can be verified during meterinstallation.

Renewal Parts

kV/kV2 MODBUS Kits

There are two kV/kV2 MODBUS kits that maybe ordered to retrofit a Modem ready kV

Meter or a kV2. Modem ready kV Meters

will have Modem Ready printed on the meter

nameplate. If the kV Meter nameplate does not

have this designation, the meter cannot be

retrofitted with a kV/kV2 MODBUS board.Any kV2 meter can be retrofitted with a

MODBUS board.

S-Base kV/kV2 MODBUS Kits

If a communications cable with a RJ-11 connector

is desired, order GE part number 9938627009.

This kit contains the following material:

Component GE Part # Qty

kV/kV2 MODBUScircuit board

99384980050 1

Cable assembly 9938583001 1

Connector holder 9938622001 1

PC board spacers 9935026005 4Wire tie 9689597010 1

MODBUS Label 9938782001 1

Instruction sheet GEI- XXXXX 1

A-base kV/kV2 MODBUS Kits

If a communications cable with an RJ-11connector is desired, order GE part number

938627010. This kit contains the following

material:

Component GE Part # Qty

kV/kV2 MODBUScircuit board

9938498050 1

Cable assembly 9938583004 1

Connector holder 9938622001 1

PC board spacers 9935026005 4

MODBUS Label 9938782001 1

Instruction sheet GEI- XXXXX 1

Note: When the kV/kV2 Meter is first

energized at the installation site, the carrier

detect LED will blink to indicate that the kV/kV2

MODBUS board is properly powered. After the

kV/kV2 MODBUS board is initialized, the

carrier detect LED will go out. If the LED does

not illuminate, or stays illuminated for more

than 5 seconds, the kV/kV2 MODBUS board is

defective and should be replaced.

Page 11

-

7/28/2019 GEH-7282

13/55

Other Renewal Parts:

Component GE Part # Qty

CommunicationsCable for S-Base

Meters, RJ-11

connector

9938583002 1

Communications

Cable for A-BaseMeters,

RJ-11 connector

9938583004 1

PC Board Spacers 9935026105 100

Page 12

-

7/28/2019 GEH-7282

14/55

Appendix A MODBUS Operation

Commands Supported

The MODBUS protocol specification can be obtained by visiting the Website http://www.modbus.org/default.htm.

The kV/kV2 MODBUS board supports a subset of the standard MODBUS commands. These are:

0x03 Read Holding Registers

0x04 Read Input Registers

0x06 Preset Single Register0x16 Preset Multiple Registers

Password and Data Access

The kV/kV2 meters do not, by themselves, support MODBUS; the native protocol for these meters is PSEM (ANSIC12.18) and AMRA Tables (ANSI C12.19). Consequently, the MODBUS board must convert MODBUS requeststo PSEM requests in order to retrieve data from the meter. Meter responses must be translated back to MODBUS

protocol before they are transmitted back to the MODBUS host. This operation is transparent to the MODBUS user

and the information is provided only as background. KV/kV2 meters are generally password-protected. In order for

the MODBUS board to retrieve meter data, it must know the meter password. MODBUS boards are shipped from

the factory with a default meter password of MASTER_012. This is stored in the MODBUS board as theequivalent sequence of hexadecimal digits. GE recommends that the user program the same password into the

meter. However, if the user wants to use a different password, it may be changed in the meter using the GE

programming software (MeterMate) and then must also be changed in the MODBUS board by writing the desiredpassword to the sequence of registers reserved for same (see register maps).

The set of data available through the MODBUS interface is a subset of the data contained in the meter(s) and

accessible through the PSEM interface. In addition, in order to gain access to the full set of MODBUS registers

listed in Appendix B, some of the meter parameters must always be programmed with predetermined, fixed values.If these fixed programming parameters are changed, behavior of the MODBUS interface is undetermined.

MODBUS Address

The MODBUS board is shipped with a default MODBUS address of 15 (0x0F). Note that a full, two-byte register is

reserved for the address; however, only the low-order byte is actually used. Each device must be assigned a newaddress that is unique for the network in which it will be installed. Valid addresses may be from 1 to 247; all other

values are reserved. The MODBUS board recognizes the universal address of 0x00. This address may be used to

communicate with individual MODBUS devices in the event that the individual address is lost or forgotten. In order

to reset the individual MODBUS address, the device must be the only one in the communication path. Then amessage can be addressed to the universal address (0x00) to tell the device to set its individual address to the desired

value. The user should then verify that the device will respond to its new address before installing it in the larger

network with other MODBUS devices.

Accessing the Data Log

Data log information may be retrieved an interval at a time. The default configuration for the interval length is 15

minutes. In general, the host system will poll the meter at regular intervals to obtain the most recent data log interval

Page 13

-

7/28/2019 GEH-7282

15/55

and the host software will keep track of the last interval read. The MODBUS board keeps track of the most recent

interval recorded; this is available in register 0x2802.

In order to retrieve a specific interval from the data log, the host software must first write the number of the desired

interval into the Data Log Interval Selector register (0x2801). Intervals are numbered from 1 to 2880, therebyproviding up to 30 days of 15-minute interval data. Fewer intervals will be available when fewer than 30 days have

elapsed since recording began.

When the MODBUS board has successfully transferred this interval data from the meter into its own buffers, it will

update the Data Log Last Read register (0x2800) to indicate that the data is now available. The host software can

then retrieve the data by reading the desired number of channels beginning at register 0x2807.

Page 14

-

7/28/2019 GEH-7282

16/55

Appendix B Register Maps

The entries in the register maps that follow correspond directly to table entries in the respective meters. MODBUS register ad

sequentially to the data items as they appear in the ANSI tables within the meters.

kV Register Map:

Dynamic Value Registers (R3 Type)

Data Type: Integer =Signed Integer (One 16-bit registers), Real =Floating Point Format (Two 16-bit registers)

Dynamic Value Registers

RegisterAddress

DDE Item Name (Mnemonic) Contents Units

3 ENERGY

2000 RESET_COUNT Number of demand resets Dimensionless

2001 KWH_IMP_TOTAL 3 KWH Import (Delivered) kWh

2003 KVAH_TOTAL 3 KVAH kVAh

2005 to

200A

UNUSED

RESERVED FOR kV2

---- ----

200B KW_MAX_DATE_IMP Date of occurrence of import (delivered)

kW max

MM/DD/YYYY

200D KW_MAX_TIME_IMP Time of occurrence of import (delivered)

kW max

HH:MM:SS.xxx

200F CUM_KW_IMP Cumulative import kW kW CUM

2011 KW_MAX_IMP 3 KW max Import kW

2013 KVA_MAX_DATE_IMP Date of occurrence of Import (delivered)

kW max

MM/DD/YYYY

2015 KVA_MAX_TIME_IMP Time of occurrence of Import (delivered) HH:MM:SS.xxx

Page 15

-

7/28/2019 GEH-7282

17/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

kW max

2017 CUM_KVA_IMP Cumulative Import (delivered) kW kW CUM

2019 KVA_MAX_TOTAL 3 KW max Import (delivered) kW

201B to

2046

UNUSED

RESERVED FOR kV2

---- ----

2047 to

215E

Space reserved for future TOU metering. These registers (bins) will store energy/demand according to a specific

calendar.

POWER FACTORS

215F PF_DMND 3 PF @ last demand Dimensionless & positive

2161 to

2168

UNUSED ---- ----

3 DEMAND &POWER

2169 CLOCK_DATE Clock date 1st 16 bitsMonth / Day (MM/DD/xx

FF00h Month

(1 =J anuary, 2 =February,..., 12 =December)

00FFh Day(1 to 31 in steps o1)

2nd 16 bitsYear (xx/xx/YYYY)

FFFFh(1990 to 2089 insteps of 1)

Page 16

-

7/28/2019 GEH-7282

18/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

NOTE: If the date has nev

been set then all 32 bits w

be 1.

216B CLOCK_TIME Clock time 1st 16 bits

Hours / Minutes

(HH:MM:xx.xxx)

FF00h Hours(0=12am, 1=1am12=12pm,...,23=11pm)

00FFh Minutes(0 to 59 in steps o1)2nd 16 bits

Seconds

(xx:xx:SS.SSS)

FFFFh(0 =00.000 s,1=00.001 s,59999=59.999 s)

NOTE: If the time has nev

been set then all 32 bits w

be 1.

216D TIME & DATE QUAL. Qualifier for date and time b0 - b2: Day of week. (0 =

Sunday6 =

Saturday

b3: Daylight savings time= True)

b4: Greenwich Mean Tim(1 = True)

b5: Time zone offset

applied (1 = True)

b6: Adjustment for daylig

Page 17

-

7/28/2019 GEH-7282

19/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

savings time (1 = True)

b7-b15: Unused

216E DMND_DATE Last demand date 1st 16 bitsMonth / Day (MM/DD/xx

FF00h Month

(1 =J anuary, 2 =Februa.., 12 =Decem)

00FFh Day(1 to 31 in steps o1)

2nd 16 bits

Year (xx/xx/YYYY)

FFFFh(1990 to 2089 in steps o

1)NOTE: If the date has nev

been set then all 32 bits wbe 1.

2170 DMND_TIME Last demand time 1st 16 bits

Hours / Minutes(HH:MM:xx.xxx)

FF00h Hours

(0=12am, 1=1am12=12pm,...,23=11pm)

00FFh Minutes(0 to 59 in steps 1)

2nd 16 bitsSeconds (xx:xx:SS.SSS)

Page 18

-

7/28/2019 GEH-7282

20/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

FFFFh(0 =00.000 s,1=00.001 s,59999=59.999 s)

NOTE: If the time has nev

been set then all 32 bits w

be 1.

2172 KW_IMP_DMND_TOTAL 3 KW IMPORT (delivered) (demand) kW

2174 KVA_DMND_TOTAL 3 KVA (demand) kVA

2176 to

217B

UNUSED

RESERVED FOR kV2

---- ----

217C KW_TOTAL_IMP 3 KW_IMP kW

217E KVA_TOTAL 3 KVA kVA

2180 to

2185

UNUSED

RESERVED FOR kV2

---- ----

CURRENT AND VOLTAGE

2186 to21ED

UNUSEDRESERVED FOR kV2

---- ----

21EE CURRENT_ANGLE_PHA

21F0 VOLTAGE_ANGLE_PHA

21F2 CURRENT_ANGLE_PHB

21F4 VOLTAGE_ANGLE_PHB

21F6 CURRENT_ANGLE_PHC

21F8 VOLTAGE_ANGLE_PHC

21FA CURRENT_MAG_PHA amps

21FC VOLTAGE_MAG_PHA volts

21FE CURRENT_MAG_PHB amps

2200 VOLTAGE_MAG_PHB volts

Page 19

-

7/28/2019 GEH-7282

21/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

2202 CURRENT_MAG_PHC amps

2204 VOLTAGE_MAG_PHC volts

2206 DU_PF %

2208 DIAG_1_COUNT Polarity, Cross Phase,

Reverse Energy Flow

2209 DIAG_2_COUNT Voltage Imbalance

220A DIAG_3_COUNT Inactive Phase Current

220B DIAG_4_COUNT Phase Angle Alert

220C DIAG_5_PHA_COUNT High Distortion

220D DIAG_5_PHB_COUNT High Distortion

220E DIAG_5_PHC_COUNT High Distortion

220F DIAG_5_TOTAL_COUNT High Distortion

2210 DIAG_6_COUNT Under Voltage, Phase A

2211 DIAG_7_COUNT Over Voltage, Phase A

2212 DIAG_8_COUNT

Single byte counts of how many times

cautions occurred.

High Neutral Current

2213 CAUTION System's Cautions b0: Cross phase, Rev ener

Flowb1: Phase Voltage Alert

b2: Inactive Phase Curren

b3: Phase Angle Alertb4: Distortion Alert

b5: Under voltage, Phase A

b6: Overvoltage, Phase A

b7: High Neutral Current

b8b15: Undefined

2214 DISTORTION_KVAH Distorted Apparent Power kVAh

2216 METER_MODE bit 0: METERING MODEbit 1: TEST MODE

bit 2-15: unused

2217 STD_STATUS Status Flags bit 0: UNPROGRAMME

bit 1: CONFIGURATION

bit 2: SELF_CHK_ERRO

Page 20

-

7/28/2019 GEH-7282

22/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

bit 3: RAM_FAILURE

bit 4: ROM_FAILURE

bit 5:

NONVOL_MEM_FAILUbit 6: CLOCK_ERROR

bit 7:

MEASUREMENT_ERRObit 8:

LOW_BATTERY_ERRO

bit 9:

LOW_LOSS_POTENTIA

bit 10:DEMAND_OVERLOAD

bit 11: POWER_FAILUR

bit 12-15: undefined

2218 MFG_STATUS Manufacturer's Status b0: DSP Errorb1: Option Board Errorb2: Watchdog Time-out E

b3: Received kWh Cautio

b4: Leading kvarh Caution

bits 5-15: Unused

DATA LOGGER

2800 DLOG_LAST_READ Data Log Latest Read Interval

2801 DLOG_INTERVAL_SELECT Data Log Interval Selector

2802 DLOG_LATEST Data Log Last Complete Interval

2803 DLOG_LATEST _DATE Data Log Latest Sample Date 1st 16 bits

Month / Day (MM/DD/xx

FF00h Month

(1 =J anuary, 2

Page 21

-

7/28/2019 GEH-7282

23/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

February,..., 12 December)

00FFh Day

(1 to 31 in steps1)

2nd 16 bitsYear (xx/xx/YYYY) FFFFh

(1990 to 2089 insteps of 1)

NOTE: If the date has nevbeen set then all 32 bits w

be 1.

2805 DLOG_LATEST _TIME Data Log Latest Sample Time 1st 16 bits

Hours / Minutes

(HH:MM:xx.xxx) FF00h Hours

(0=12am,1=1am,...,12=12pm,...,23=11pm)

00FFh Minutes(0 to 59 in steps1)

2nd 16 bits

Seconds (xx:xx:SS.SSS)

FFFFh

(0 =00.000 s,

1=00.001 s,59999=59.999 s

NOTE: If the time has nevbeen set then all 32 bits wi

be 1.

Page 22

-

7/28/2019 GEH-7282

24/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

2807 Channel 1 3 kW Demand

2809 Channel 2 3 kVA Demand

280B Channel 3 3 PF @ last demand

280D Channel 4 3 kWh

280F Channel 5 3 kVAh

2811 Channel 6 Not used in kV

2813 Channel 7 Not used in kV

2815 Channel 8 Not used in kV

OTHER STATUS (future!!!)

A value of 0 indicates that no valid interval data is present in the MODBUS board. A value of 0 indicates that the meter has not yet recorded any interval data.

Page 23

-

7/28/2019 GEH-7282

25/55

Fixed Value Registers (R4 TYPE)

Fixed Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units/Value/Range

3000 MODBUS_ADDR Modbus Address Dimensionless

3001 COMM_BOARD_PASSWORD Must match the meters master

password; default is MASTER_012

(hexadecimal 4D 41 53 54 45 52 5F30 31 32)

10-byte ASCII

3006 58 REGISTERS RESERVED FOR EEPROM DATA

3040 PRODUCT_ID Product Id 1

3041 MODBUS_REV Modbus S/W Revision 4 character string with 2 place decim

3043 MANUFACTURER Name of manufacturer "GE "

3045 ED_MODEL Meter Model "kV2 "

3049 METER_HW_REV Meter H/W Revision and Version

number

MSB implies functional differences

implies product corrections or

improvements

304A METER_SW_REV Meter Firmware Revision number MSB implies functional differences

implies product corrections or

improvements

304B SERIAL_NUM Serial Number alphanumeric (8 Registers)

3053 IDENTIFICATION ID of the kV2 meter 20 ASCII characters

306C SECURITY_FLAGS Prevent MeterMate from writing into

Canadian meter in the field

b0: Meter Sealed if set

b1: If set, demand resets are prevenb2: If set, allows access with any (r

password restricted to modifying

thecustomer/reader password(s) i

table only.

Page 24

-

7/28/2019 GEH-7282

26/55

Page 25

-

7/28/2019 GEH-7282

27/55

Fixed Setpoint Registers (GENERAL)

RegisterAddress

DDE Item Name (Mnemonic) Contents Units/Value/Range

3100 LENGTH_OF_DEMAND_INTERVAL Demand Intervallength Minutes5, 6, 10, 12, 15, 20, 30 or 60

3101 NO_OF_SUB_INTERVAL Number of sub-

intervals

Number of subs

1 to 15, valid combinations of demand interva

length and number of subintervals listed belowSub length No. of subs

5 1, 5

6 1, 2, 3, 6

10 1, 2, 5, 1012 1, 2, 3, 4, 6

15 1, 3, 5

20 1, 2, 4, 5, 10

30 1, 2, 3, 5, 6, 1060 1, 2, 3, 4, 5, 6, 10

DATA LOGGER

3200 DATA_LOG_MEM_ LENGTH Reserved bytes for Data Logger in kV meter

3202 DATA_LOG_FLAGS Reserved

3203 DATA_LOG_FORMAT Reserved

3204 NBR_BLOCKS Number of blocks

3205 NBR_INTS_PER_BLOCK Number of Intervals per block

3206 NBR_CHANNELS Number of channels

3207 LOG_INTERVAL Log Interval lengthMSB has to be

masked

Minutes1, 5, 10, 15, 30, or 60

Commands or Procedures

Page 26

-

7/28/2019 GEH-7282

28/55

Command

Register

Address

DDE Item Name

(Mnemonic)

Contents Units/Value R/W Data

Type

4000 CLEAR_DMND Clear Watt Demand 0 WO Discrete

4001 MTR_INITIALIZE Initialize meter 0 WO Discrete4002 CLEAR_ERROR Clear Meter Errors 0 WO Discrete

Page 27

-

7/28/2019 GEH-7282

29/55

kV2 Register Map:

Dynamic Value Registers (R3 Type)

Data Type: Integer =Signed Integer (One 16-bit registers), Real =Floating Point Format (Two 16-bit registers)

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

3 ENERGY

2000 RESET_COUNT Number of demand resets Dimensionless

2001 KWH_IMP_TOTAL 3 KWH Import (Delivered) kWh

2003 KWH_EXP_TOTAL 3 KWH Export (received) kWh

2005 KVARH_LG_TOTAL 3 KVARH lag kVARh

2007 KVARH_LD_TOTAL 3 KVARH lead kVARh

2009 KVAH_TOTAL 3 KVAH kVAh

200B KW_MAX_DATE_IMP Date of occurrence of import

(Delivered) kW max

MM/DD/YYYY

200D KW_MAX_TIME_IMP Time of occurrence of import

(Delivered) kW max

HH:MM:SS.xxx

200F CUM_KW_IMP Cumulative import (Delivered) kW kW CUM

2011 KW_MAX_IMP 3 KW max Import kW

2013 KW_MAX_DATE_EXP Date of occurrence of Export

(received) kW max

MM/DD/YYYY

2015 KW_MAX_TIME_EXP Time of occurrence of Export

(received) kW max

HH:MM:SS.xxx

2017 CUM_KW_EXP Cumulative Export (received) kW kW CUM

Page 28

-

7/28/2019 GEH-7282

30/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

2019 KW_MAX_EXP 3 KW max Export (received) kW

201B KVAR_LG_MAX_DATE Date of occurrence of kvar lag max MM/DD/YYYY

201D KVAR_LG_MAX_TIME Time of occurrence of kvar lag max HH:MM:SS.xxx

201F CUM_ KVAR_LG_MAX Cumulative kvar max lag kW CUM

2021 KVAR_LG_MAX_TOTAL 3 KVAR lag max kVAR

2023 KVAR_LD_MAX_DATE Date of occurence of kvar max lead MM/DD/YYYY

2025 KVAR_LD_MAX_TIME Time of occurence of kvar max lead HH:MM:SS.xxx

2027 CUM_ KVAR_LD_MAX Cumulative kvar max lead kW CUM

2029 KVAR_LD_MAX_TOTAL 3 KVAR lead max kVAR 202B KVA_MAX_DATE_TOTAL Date of occurence of import

(Delivered) kVA max

MM/DD/YYYY

202D KVA_MAX_TIME_TOTAL Time of occurence of import

(Delivered) kVA max

HH:MM:SS.xxx

202F CUM_KVA_TOTAL Cumulative kVA max kVACUM

2031 KVA_MAX_TOTAL 3 KVA max kVA

2033 to2042

Reserved for later defined coincident demand These are registers keeping the value of selected current demandscoincident to the registration of maximum demands. Two registers for each maximum demand.

2043 KW_IMP_AT_KVA_MAX 3 KWimp @ KVAmax kW

2045 KW_EXP_AT_KVA_MAX 3 KWexp @ KVAmax kW

2047

to

215E

Space reserved for future TOU metering. These registers (bins) will store energy/demand according to a specific

calendar. Whether we will go with TOU metering for CAM remains to be discussed.

POWER FACTORS

215F PF_DMND 3 PF @ last demand Dimensionless

Page 29

-

7/28/2019 GEH-7282

31/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

2161 PF_AT_KVA_MAX 3 PF @ KVAmax Dimensionless

2163 PF_A 1 PF, Phase A Dimensionless 2165 PF_B 1 PF, Phase B Dimensionless

2167 PF_C 1 PF, Phase C Dimensionless

3 DEMAND &POWER

2169 CLOCK_DATE Clock date 1st 16 bits

Month / Day (MM/DD/xxxx)

FF00h Month(1 =J anuary, 2 =February,..., 12 =December)

00FFh Day

(1 to 31 in steps of1)2nd 16 bitsYear (xx/xx/YYYY)

FFFFh

(1990 to 2089 insteps of 1)

NOTE: If the date has never

been set then all 32 bits will

be 1.

Page 30

-

7/28/2019 GEH-7282

32/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

216B CLOCK_TIME Clock time 1st 16 bits

Hours / Minutes

(HH:MM:xx.xxx)

FF00h Hours(0=12am,1=1am,...,12=12pm,...,23=11pm)

00FFh Minutes(0 to 59 in steps of1)

2nd 16 bits

Seconds (xx:xx:SS.SSS)

FFFFh(0 =00.000 s,1=00.001 s,59999=59.999 s)

NOTE: If the time has neverbeen set then all

32 bits will be 1.

216D TIME & DATE QUAL. Qualifier for date and time b0 - b2: Day of week. (0 =

Sunday6 =

Saturday

b3: Daylight savings time (1

= True)b4: Greenwich Mean Time

(1 = True)

b5: Time zone offset

applied (1 = True)b6: Adjustment for daylight

savings time (1 = True)

b7-b15: Unused

Page 31

-

7/28/2019 GEH-7282

33/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

216E DMND_DATE Last demand date 1st 16 bits

Month / Day (MM/DD/xxxx)

FF00h Month

(1 =J anuary, 2 =February,..., 12 =December)

00FFh Day

(1 to 31 in steps of1)2nd 16 bits

Year (xx/xx/YYYY) FFFFh

(1990 to 2089 insteps of 1)

NOTE: If the date has never

been set then all 32 bits willbe 1.

2170 DMND_TIME Last demand time 1st 16 bitsHours / Minutes

(HH:MM:xx.xxx)

FF00h Hours(0=12am,1=1am,...,12=12pm,...,23=11pm)

00FFh Minutes(0 to 59 in steps of1)

2nd 16 bitsSeconds (xx:xx:SS.SSS)

FFFFh(0 =00.000 s,1=00.001 s,

Page 32

-

7/28/2019 GEH-7282

34/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

59999=59.999 s)NOTE: If the time has never

been set then all 32 bits will

be 1.

2172 KW_IMP_DMND_TOTAL 3 kW IMPORT (Delivered)(demand)

kW

2174 KW_EXP_DMND_TOTAL 3 kW EXPORT (RECEIVED)(demand)

kW

2176 KVAR_LG_DMND_TOTAL 3 kVAR lag (demand) kVAR

2178 KVAR_LD_DMND_TOTAL 3 kVAR lead (demand) kVAR

217A KVA_DMND_TOTAL 3 kVA (demand) kVA

217C KW_TOTAL_IMP 3 kW_IMP kW

217E KW_TOTAL_EXP 3 kW_EXP kW

2180 KVAR_TOTAL_LG 3 kVAR_LAG kVAR

2182 KVAR_TOTAL_LD 3 kVAR_LEAD kVAR

2184 KVA_TOTAL 3 kVA kVA

1 POWER & FREQUENCY

2186 KW_FUND_HARM_A kW

2188 KW_FUND_HARM_B kW

218A KW_FUND_HARM_C kW

218C KW_A 1 kW, Phase A kW

218E KW_B 1 kW, Phase B kW

2190 KW_C 1 kW, Phase C kW

2192 KVAR_FUND_HARM_A

2194 KVAR_FUND_HARM_B

2196 KVAR_FUND_HARM_C

2198 KVAR_A 1 kVAR, Phase A kVAR

219A KVAR_B 1 kVAR, Phase B kVAR

219C KVAR_C 1 kVAR, Phase C kVAR

Page 33

-

7/28/2019 GEH-7282

35/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

219E DISTORTION_KVA_A

21A0 DISTORTION_KVA_B

21A2 DISTORTION_KVA_C

21A4 APPARENT_KVA_A 1 kVA, Phase A kVA

21A6 APPARENT_KVA_B 1 kVA, Phase B kVA

21A8 APPARENT_KVA_C 1 kVA, Phase C kVA

CURRENT AND VOLTAGE

21AA V_FUND_HARM_A volts

21AC V_FUND_HARM_B volts

21AE V_FUND_HARM_C volts

21B0 VOLTS_A VOLTAGE L-N phase A-N volts

21B2 VOLTS_B VOLTAGE L-N phase B-N volts 21B4 VOLTS_C VOLTAGE L-N phase C-N volts

21B6 V_FUND_HARM_AB volts

21B8 V_FUND_HARM_BC volts

21BA V_FUND_HARM_CA volts

21BC VOLTS_AB VOLTAGE L-L phase A-B volts

21BE VOLTS_BC VOLTAGE L-L phase B-C volts

21C0 VOLTS_CA VOLTAGE L-L phase C-A volts

21C2 AMPS_FUND_HARM_A amps

21C4 AMPS_FUND_HARM_B amps

21C6 AMPS_FUND_HARM_C amps

21C8 AMPS_A Current Phase A amps

21CA AMPS_B Current Phase B amps 21CC AMPS_C Current Phase C amps

21CE AMPS_N Current Neutral amps

21D0 PF 3 PF DimensionlessPositive =lagging

Negative =leading

Page 34

-

7/28/2019 GEH-7282

36/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

21D2 FREQUENCY 3 Frequency Hz

21D4 TDD_A Total demand distortion, Phase A %

21D6 TDD_B Total demand distortion, Phase B %

21D8 TDD_C Total demand distortion, Phase C %

21DA ITHD_A Current, total harm. dist., Phase A %

21DC ITHD_B Current, total harm. dist.,. Phase B %

21DE ITHD_C Current, total harm. dist., Phase C %

21E0 VTHD_A Voltage, total harm. dist., Phase A %

21E2 VTHD_B Voltage, total harm. dist., Phase B %

21E4 VTHD_C Voltage, total harm. dist., Phase C %

21E6 DISTORTION_PF_A Distortion Power Factor, Phase A %

21E8 DISTORTION_PF_B Distortion Power Factor, Phase B %

21EA DISTORTION_PF_C Distortion Power Factor, Phase C %

21EC DISTORTION_PF_TOTAL Total distortion power factor %

21EE CURRENT_ANGLE_PHA

21F0 VOLTAGE_ANGLE_PHA

21F2 CURRENT_ANGLE_PHB

21F4 VOLTAGE_ANGLE_PHB

21F6 CURRENT_ANGLE_PHC

21F8 VOLTAGE_ANGLE_PHC

21FA CURRENT_MAG_PHA amps

21FC VOLTAGE_MAG_PHA volts

21FE CURRENT_MAG_PHB amps

2200 VOLTAGE_MAG_PHB volts

2202 CURRENT_MAG_PHC amps 2204 VOLTAGE_MAG_PHC volts

2206 DU_PF %

2208 DIAG_1_COUNT Polarity, Cross Phase,Reverse Energy Flow

2209 DIAG_2_COUNT

Voltage Imbalance

Page 35

-

7/28/2019 GEH-7282

37/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

220A DIAG_3_COUNT Inactive Phase Current

220B DIAG_4_COUNT Phase Angle Alert

220C DIAG_5_PHA_COUNT High Distortion

220D DIAG_5_PHB_COUNT High Distortion

220E DIAG_5_PHC_COUNT High Distortion

220F DIAG_5_TOTAL_COUNT High Distortion

2210 DIAG_6_COUNT Under Voltage, Phase A

2211 DIAG_7_COUNT Over Voltage, Phase A

2212 DIAG_8_COUNT

Single byte counts of how manytimes cautions occurred.

High Neutral Current

2213 CAUTION System's Cautions b0: Cross phase, Rev energy

Flow

b1: Phase Voltage Alertb2: Inactive Phase Current

b3: Phase Angle Alert

b4: Distortion Alertb5: Under voltage, Phase A

b6: Overvoltage, Phase A

b7: High Neutral Current

b8b15: Undefined

2214 RESERVED

2215 RESERVED

2216 METER_MODE bit 0: METERING MODE

bit 1: TEST MODEbit 2-15: unused

2217 STD_STATUS Status Flags bit 0: UNPROGRAMMEDbit 1: CONFIGURATION

bit 2: SELF_CHK_ERROR

bit 3: RAM_FAILUREbit 4: ROM_FAILURE

bit 5:

NONVOL_MEM_FAILURE

bit 6: CLOCK_ERROR

Page 36

-

7/28/2019 GEH-7282

38/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

bit 7:

MEASUREMENT_ERROR

bit 8:

LOW_BATTERY_ERRORbit 9:

LOW_LOSS_POTENTIAL

bit 10:DEMAND_OVERLOAD

bit 11: POWER_FAILURE

bit 12-15: undefined

2218 MFG_STATUS Manufacturer's Status b0: DSP Error

b1: Option Board Error

b2: Watchdog Time-out Error

b3: Received kWh Cautionb4: Leading kvarh Caution

bits 5-15: Unused

DATA LOGGER

2800 DLOG_LAST_READ Data Log Latest Read Interval

2801 DLOG_INTERVAL_SELECT Data Log Interval Selector

2802 DLOG_LATEST Data Log Last Complete Interval

2803 DLOG_LATEST _DATE Data Log Latest Sample Date 1st 16 bitsMonth / Day (MM/DD/xxxx)FF00h Month

(1 = January, 2 = February,..., 12= December)00FFh Day

(1 to 31 in steps of 1)2nd 16 bitsYear (xx/xx/YYYY)FFFFh(1990 to 2089 in steps of 1)

NOTE: If the date has never

Page 37

-

7/28/2019 GEH-7282

39/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

been set then all 32 bits will be1.

2805 DLOG_LATEST _TIME Data Log Latest Sample Time 1st 16 bitsHours / Minutes

(HH:MM:xx.xxx)

FF00h Hours(0=12am, 1=1am,...,

12=12pm,..,23=11pm)

00FFh Minutes(0 to 59 in steps of 1)2nd 16 bitsSeconds (xx:xx:SS.SSS)

FFFFh

(0 =00.000 s, 1=00.001 s,59999=59.999 s)

NOTE: If the time has never

been set then all 32 bits will

be 1.

2807 DLOG_SS_00 Channel 1 3 KW Demand

2809 DLOG_SS_01 Channel 2 3 KVAR Demand

280B DLOG_SS_02 Channel 3 3 KVA Demand

280D DLOG_SS_03 Channel 4 3 PF @ last demand

280F DLOG_SS_04 Channel 5 3 KWH Import (Delivered)

2811 DLOG_SS_05 Channel 6 3 KWH Export (received)

Page 38

-

7/28/2019 GEH-7282

40/55

Dynamic Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units

2813 DLOG_SS_06 Channel 7 3 KVARH lag

2815 DLOG_SS_07 Channel 8 3 KVARH lead

A value of 0 indicates that no valid interval data is present in the MODBUS board. A value of 0 indicates that the meter has not yet recorded any interval data.

Fixed Value Registers (R4 TYPE)

Fixed Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units/Value/Range

3000 MODBUS_ADDR Modbus Address Dimensionless

3001 COMM_BOARD_PASSWORD Must match the meters master

password; default is MASTER_012(hexadecimal 4D 41 53 54 45 52 5F

30 31 32)

10 alphanumeric

3006 58 REGISTERS RESERVED FOR EEPROM DATA

3040 PRODUCT_ID Product Id 1

3041 MODBUS_REV Modbus S/W Revision 4 character string with 2 place

decimal

3043 MANUFACTURER Name of manufacturer "GE "

3045 ED_MODEL Meter Model "kV2 "

3049 METER_HW_REV Meter H/W Revision and Version

number

MSB implies functional differences;

LSB implies product corrections or

improvements

304A METER_SW_REV Meter Firmware Revision number MSB implies functional differences;LSB implies product corrections or

improvements

Page 39

-

7/28/2019 GEH-7282

41/55

Fixed Value Registers

Register

Address

DDE Item Name (Mnemonic) Contents Units/Value/Range

304B SERIAL_NUM Serial Number alphanumeric (8 Registers)

3053 IDENTIFICATION ID of the kV2 meter 20 ASCII characters

305D MASTER PASSWORD High order 10 ASCII characters = 5

REGISTERS

3062 READER PASSWORD Medium order 10 ASCII characters

3067 CUSTOMER PASSWORD Low order 10 ASCII characters

306C SECURITY FLAGS Prevent MeterMate from writing

into Canadian meter in the field

b0: Meter Sealed if set

b1: If set, demand resets areprevented

b2: If set, allows access with any(reader) password restricted to

modifying thecustomer/reader

password(s) in this table only.

Page 40

-

7/28/2019 GEH-7282

42/55

Fixed Setpoint Registers (GENERAL)

Register

Address

DDE Item Name (Mnemonic) Contents Units/Value/Range

3100 LENGTH OF DEMAND INTERVAL Demand Interval length Minutes1, 2, 3, 4, 5, 6, 10, 15, 20, 30

or 60

3101 NO OFSUB_INTERVAL

Number of sub-intervals Number of subs1 to 15, valid combinations of

demand interval length and

number of subintervals listed

below:Sub length No. of

subs

1 1, 2, 3, 4, 5, 6,

10, 12, 152 1, 2, 3, 6, 10,

15

3 1, 2, 4, 5, 104 1, 3, 5, 15

5 1, 3, 4, 6,12

6 1, 2, 5, 10

10 1, 2, 3, 6

15 1, 2, 320 1, 3

30 1, 2

60 1

DATA LOGGER

3200 DATA_LOG_MEM_ LENGTH Reserved bytes for DataLogger in kV meter

3202 DATA_LOG_FLAGS Reserved

3203 DATA_LOG_FORMAT Reserved

3204 NBR_BLOCKS Number of blocks

Page 41

-

7/28/2019 GEH-7282

43/55

Fixed Setpoint Registers (GENERAL)

Register

Address

DDE Item Name (Mnemonic) Contents Units/Value/Range

3205 NBR_INTS_PER_BLOCK Number of Intervals per block

3206 NBR_CHANNELS Number of channels 3207 LOG_INTERVAL Log Interval length

MSB has to be masked

Minutes

1,2,3,4,5,6,10,12,15,20,30, or

60

Commands or Procedures

Command

Register

Address

DDE Item Name

(Mnemonic)

Contents Units/Value R/W Data

Type

4000 CLEAR_DMND Clear Watt Demand 0 WO Discrete

4001 MTR_INITIALIZE Initialize meter 0 WO Discrete

4002 CLEAR_ERROR Clear Meter Errors 0 WO Discrete

Page 42

-

7/28/2019 GEH-7282

44/55

Appendix C - Replacing the Cable Connector

The EIA-485 standard does not specify a standard connector for RS-485 communications. The MODBUS

board will be shipped with a cable terminated with an RJ-11 connector. This connector may be replaced

with a connector appropriate for the destination network by following the diagram below.

BLU

YEL

GRN

RED

BLK

WHT

1

2

3

4

5

6

TX+

TX-

RX+

RX-

COM

DATA B

DATA ACOM

kV/kV2 MODBUS Cable(RJ -11 termination)

MODBUSConnector

MODBUS Cable Connector Wiring

Page 43

-

7/28/2019 GEH-7282

45/55

Appendix D

Network Architecture and Wiring

Modbus Wiring Rules Diagrams

The Modbus network protocol has wiring rules and limits on the number of IEDs that may be attached.This section describes in greater detail the rules you must follow when designing a Modbus network.

NOTE: It is important to take future expandability

into consideration when designing a network

configuration. This is particularly so when thenetwork is near its maximum number of IEDs or

maximum cable length. Adding IEDs to a networkafter it has been installed may require rewiring the

network.

CAUTION: Wire-run distances mentioned in the

configuration rules assume application above grade

or in conduit. For below-grade applications, refer toSection 31, Wiring Requirements.

Regardless of which platform is supporting the RS-485 networks (Ethernet Gateway, RS-485 card, or RS-232/RS-

485 converter), the following rules apply to each individual RS-485 network.

1. Each RS-485 network may support up to 31 Modbus IEDs. Figure 2 illustrates this rule. (See the exception

below Figure 6.)

31 RS-485 IEDs maximum;

PMCS Host PC, Ethernet Gateway or MSP

always located at one end of Modbus network.

Host

Figure 2. Network illustrating Modbus Rules 1 and 2.

Exception to Rule 1: Some types of IEDs must be wired on dedicated private serial network segments, one IED per

serial Modbus line.

2. The host (or Ethernet Gateway) must always be located at one end of any Modbus segment. It may not belocated in the center of a Modbus network. Figure 2 shows the correct placement of the host (PC or Ethernet

Gateway).

3. All Modbus IEDs on a single RS-485 network must communicate at the same baud rate. If IEDs with different

communication speeds are connected to the same RS-485 network, the whole segment will communicate at thespeed of the slowest IED. Figure 3 illustrates this rule. (Communication speeds for supported IEDs are listed in

Table 1.)

Page 44

-

7/28/2019 GEH-7282

46/55

Figure 3. Network illustrating Modbus Rule 3.

4. Each RS-485 network must be properly terminated at both ends of the cable run after the final IED. Figure 4

illustrates this rule.5. Each RS-485 network must have its shield properly grounded. Figure 4 illustrates proper RS-485 wiring and

grounding.

CAUTION: Improper grounding may create aground-loop condition and cause communications

failures. Make sure you follow the wiring diagram

carefully.

To ensure proper grounding, follow this procedure. Begin by grounding the RS-485 cable shield at the host. Follow

the cable to the first IED on the network. Do NOT connect the cable ground to the IED. Pick up the RS-485 output

cable from the IED and attach its ground to the IEDs shield connection or grounding screw. For IEDs with nogrounding connectors, connect to earth ground.

Follow the cable to the next IED, and repeat the above procedure. Do not connect the RS-485 shield from the

previous IED, but DO connect the RS-485 OUT shield on its way to the next IED.

EXCEPTION: The Multilin 565 Feeder

Management Relay does not have isolated

communications ports. Do NOT connect the shield at

this IED. Instead connect the shield of the incomingRS-485 cable to the shield of the outgoing RS-485

cable, skipping the Multilin 565.

Rules of thumb: RS-485 cable ground should always be connected at the previous IED, never upon arrival at an

IED. All RS-485 IEDs must have either two communications cables attached or one communications cable and a

terminating resistor.

Page 45

-

7/28/2019 GEH-7282

47/55

RS-485 Host

(RS-485 card*, RS232/RS-485 converter,

Multiple Serial Port or Ethernet Gateway RS-485 port)

Network Connections: + - Shield

RS-485 IED #1

Shield

+

-

RS-485 IED #2

Shield

+

-

Two wire, twisted,

shielded pair cable

RS-485

RS-485 IED #31

Shield

+

-

120-ohm

terminating resistor

Shield

connected

at host

Shield not

connected

at first IED

RS-485 IN

Shield

connected

at first IED

RS-485 OUT

Shield not

connected

at IED

RS-485 IN

Shield

connected

at IED

RS-485 OUT

Shield not

connected

at IED

RS-485 IN

120-ohm terminating resistor

* Connect Tech RS-485 cards

require a 600-ohm resistor

in place of the 120-ohmterminating resistor.

Figure 4. Network illustrating Modbus Rules 4 and 5.

6. A single RS-485 network may have up to 215 commnet IEDs attached to it via POWER LEADER Modbus

Concentrators. Figure 5 illustrates this rule.

Page 46

-

7/28/2019 GEH-7282

48/55

RS-485 IEDs

(31 Max)

Host

Modbus

Concentrator

MC

Commnet IEDs

(up to 32 per Modbus Concentrator,

215 total per RS-485 network)

Figure 5. Network illustrating Modbus Rule 6.

7. A single RS-485 network may have no more than 4000 feet of cable (total cable length, not distance between

IEDs). Figure 6 illustrates this rule.

RS-485 IEDs

(31 Max)Host

Total Cable Length < 4000 feet

100 ft

300 ft

1500 ft

1500 ft

200 ft 300 ft

Figure 6. Network illustrating Modbus Rule 7.

8. RS-485 repeaters may be used to extend the range beyond 4000 feet. A single RS-485 repeater may be used toprovide a 4000-foot extension, and each additional repeater in a sequence extends the range by another 4000

feet. Figure 7 illustrates this rule.

With 2 Repeaters,

Total Cable Length < 8000 feet

Host100 ft

200 ft 2500 ft

500 ft 700 ft

4000 ft

R

R

RS-485

Repeaters

Figure 7. Network illustrating Modbus Rule 8.

9. There may be no more than two RS-485 repeaters between any two RS-485 IEDs. Figure 8 illustrates this rule.

Correct - Maximum two repeaters between RS-485 IEDs

Incorrect - more than 2 repeaters between RS-485 IEDs

Rptr Rptr Rptr

Rptr Rptr

Figure 8. Network illustrating Modbus Rule 9.

Page 47

-

7/28/2019 GEH-7282

49/55

Network Wiring and Construction

Once the network has been carefully laid out on paper and IED addresses have been planned, you need to check the

following wiring requirements before beginning assembly of the system.

WARNING: Network wiring and grounding rules described herein apply primarily to commeand industrial installations. Substation installations will exist in the presence of dangerously

elevated ground potential relative to points outside of the station grid as well as large

electromagnetic induction fields. Additionally, large ground faults can elevate substation groupotentials. Follow local utility best-practices and safety procedures to prevent risk of shock or

electrocution to personnel and damage to equipment that could result in a loss of protection a

communications.

CAUTION: The recommended installation practice is to implement optical fiber for connecti

between buildings to provide electrical isolation. This eliminates harmful ground loops cause

differences in the ground potential between structures.

CAUTION: Data line surge protection is recommended for network components such as hubscomputers, or modems connected to IEDs with copper wire, especially installations where the

data communication cable is exposed (i.e., not encased in conduit) or runs parallel to power

conductors. IEDs are routinely installed in areas exposed to heavy electromagnetic fields (EM

which can induce damaging surges in data communication lines. Data line surge protection is

required for fiber optic connections.

Page 48

-

7/28/2019 GEH-7282

50/55

Wiring Requirements

Modbus has unique wiring requirements. These rules are summarized following.

WARNING: The National Electrical Code (NEC)

and all applicable local codes must be followedwhen installing wiring.

Type of Wire

Belden 9841 or Alpha 6412 may be used for applications under 300 V that are indoors or outdoors in conduit above

grade. These cables may be also be used for 600 V requirements by applying 600 V tubing to them. Belden 3074F

may be used for applications greater than 300 V which are indoors or outdoors in conduit above grade.

Termination

RS-485 cables must be terminated at each end of the network with a 120-ohm, 1/2-watt, 5% tolerance resistor.

IMPORTANT NOTE FOR CONNECT TECH

CARD USERS: The Connect Tech RS-485 cardrequires a 600-ohm rather than a 120-ohm resistor.

Use the 600-ohm resistor at the Connect Tech card

only. The other end of the Modbus network(s)

should be terminated with the usual 120-ohm

resistor.

See Figure 4 for an example of the cable run terminated at the final IED on the network.

Shield Grounding

The RS-485 cable shield must be grounded at only a single point on each RS-485 wire. Connect the shield to the

ground terminal at the Ethernet Gateway or RS-485 interface card. Connect the cable shield to the shield terminal ateach IED on the RS-485 network except the Multilin 565, which does not have isolated communication ports

(Modbus Rule 5, Section 24).

Page 49

-

7/28/2019 GEH-7282

51/55

Local Configuration of IEDs

You must properly configure each IED connected to the host software. Be sure to set the IED address at the IED and

at the host software, set the communication speed, and configure any necessary settings.

For detailed directions on setting addresses, communication speed, and protection parameters, refer to the user guide

for each IED.

Applying Power to the System

WARNING:

Voltages hazardous to personnel and equipment may be present at the power connections.

Once youve installed the network, you should apply power to the network from the bottom up. Follow thisprocedure when applying power to the system for the first time:

1. Make sure that all communications wiring has been correctly connected to each IED and that the systemmatches the plan exactly, meeting all rules and requirements explained in this manual.

2. Make sure that all wiring for control power to IEDs has been correctly installed and that the correct controlvoltage is present at each IED.

3. If commnet IEDs are installed, apply control power to the IEDs and then to the Modbus Concentrator to which

they are attached.4. Apply control power to any Modbus RTU IEDs.

5. Apply control power to the Ethernet Gateway, if one is being used.

6. Turn the computer on and start the host software according to the instructions in the software manuals.

Page 50

-

7/28/2019 GEH-7282

52/55

Trouble-Shooting Guide

Symptom Possible Cause Corrective Action

1. No communication to one

or more Modbus IEDs;

some IEDs OK.

The IED or a repeater is not

powered.

Check that control power is supplied to all IEDs and

repeaters. If the IED or repeater does not operate when

control power is present, contact the GE Resolution Center

at 1-888-GE-RESOLV.

RS-485 wiring is shorted orimproperly connected.

Locate and remove the short or incorrect connection.

An RS-485 shield has been

grounded incorrectly.

Refer to Section 24, Rule 5 for proper RS-485 grounding

considerations. Recheck the RS-485 network forcompliance. Improper grounding can cause communication

errors.

The network configuration is

incorrect.

Check that the network conforms to rules regarding RS-485

wiring above.The IED is not addressed. Ensure that each IEDs Modbus address corresponds to the

address set at the host software.

Two or more Modbus IEDs

have the same address.

Check IEDs for duplicate address assignments. Change the

address of the affected IED, then attempt to communicate

with the original address to see if another IED has thataddress.

Check any dual-port IEDs to be sure that each RS-485 portis wired to a separate RS-485 network.

2. No communication to anyIEDs on one commnet

segment.

The IEDs or a Repeater on thatsegment is not powered.

Check that control power is supplied to all IEDs. Checkthat two LEDs are lit on each Repeater, indicating that

control power is present. If the IED or Repeater does not

operate when control power is present, contact the GE

Resolution Center at 1-888-GE-RESOLV.Commnet wires are shorted or

improperly connected.

Locate and remove the short or incorrect connection.

The network configuration of

the segment is incorrect.

Check that the segment conforms to Rules 1 through 5 in

Chapter 2 regarding the number of IEDs permitted percommnet segment and wiring requirements and limitations.

3. Intermittent communi-

cation to an IED (Modbus

or commnet).

The network configuration is

incorrect.

Check that the network conforms to the rules in Chapter 2.

The IED or a Repeater is notpowered or has inconsistent

power.

Check the control power supplied to the IED and to anyRepeaters on the network or segment.

Two or more IEDs on thenetwork have the same address.

Check the host for duplicate address assignments. Changethe address of the affected IED, then attempt to

communicate with the original address to see if another

IED has that address.

Page 51

-

7/28/2019 GEH-7282

53/55

Appendix E - Meter Programming Parameters

Required Programming Parameters

Use GEs MeterMate software to program your kV/kV2 meters. Be sure you have the required soft-

switches enabled in the meters. The following items must be programmed exactly as specified in order for

the MODBUS board to function correctly with a kV/kV2 Meter. Quantities to be metered must be assigned

in the specified order. Any programmed parameters not explicitly restricted below may be programmed as

the user requires.

KV Meter

Required Soft-switches

A, K, R, T

Demand Metering

Demand Interval Length 15 Minutes

Demand Interval Type Block

Billing Measures

kWh Total Del Only

kvah Total Lag-Lead

Demand Measures

kW Total Del Onlykva Total Lag-Lead

Recorder Options

Option Board Memory Configuration Both Load Profile & Self ReadLoad Profile Interval Length 15

Load Profile # Channels 2

Channel Configuration

Channel 1 kWh

Channel 1 Scale Factor 1Channel 2 Alternate Measure

Channel 2 Scale Factor 1

Alternate Measure kVAh

KV2 Meter

Required Soft-switches

A, K, Q, T, X

Measurement Profiles (Order is not important)

No of Measurements in Profile 7kWh Total Del Only F+H

Page 52

-

7/28/2019 GEH-7282

54/55

kWh Total Rcvd Only F+H

kWh Total Del+Rcvd F+H

kvarh Total Lag Only F+H IEEE

kvarh Total Lead Only F+H IEEE

kvarh Total Lag+Lead F+H IEEEPhasor kVAh F+H IEEE

Demand Metering

Demand Interval Length 15 Minutes

Demand Interval Type Block

Billing Measures

kWh Total Del Only F+H

kWh Total Rcvd Only F+H

kvarh Total Lag Only F+H IEEEkvarh Total Lead Only F+H IEEE

Phasor kVAh F+H IEEE

Demand Measures

kW Total Del Only F+HkW Total Rcvd Only F+H

kvar Total Lag Only F+H IEEE

kvar Total Lead Only F+H IEEEPhasor kVA F+H IEEE

Coincident Demands

kW Total Del Only F+H Coincident to Phasor kVA F+H IEEE (Demand 5)kW Total Recd Only F+H Coincident to Phasor kVA F+H IEEE (Demand 5)

Average PF - NumeratorkWh Total Del Only F+H

Average PF - Denominator

Phasor kVAh F+H IEEE

Recorder Option

Days of LP Memory 30Load Profile Interval Length 15

Load Profile # Channels 8

Channel Configuration

Channel 1 kWh Total Del+Rcvd F+H

Channel 1 Scale Factor 1

Channel 2 kvarh Total Lag+Lead F+H IEEE

Channel 2 Scale Factor 1Channel 3 Phasor kVAh F+H IEEE

Channel 3 Scale Factor 1

Channel 4 kWh Total Del Only F+H*

Channel 4 Scale Factor 1Channel 5 kWh Total Del Only F+H

Channel 5 Scale Factor 1Channel 6 kWh Total Rcvd Only F+H

Channel 6 Scale Factor 1

Channel 7 kvarh Total Lag Only F+H IEEE

Page 53

-

7/28/2019 GEH-7282

55/55

Channel 7 Scale Factor 1

Channel 8 kvarh Total Lead Only F+H IEEE

Channel 8 Scale Factor 1

* This is place holder only; the MODBUS board will compute the data for this channel.