Ko Einbau en Web

-

Upload

napau-adelin -

Category

Documents

-

view

220 -

download

0

Transcript of Ko Einbau en Web

7/28/2019 Ko Einbau en Web

http://slidepdf.com/reader/full/ko-einbau-en-web 1/7

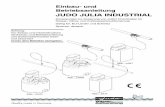

MS Motor Service International GmbH74196 Neuenstadt, Germanywww.ms-motor-service.com

KOLBEN

PISTON

40 013 600

2 x Z17

128,000 mm

verwendbar für / suitable for

MERCEDES BENZ

6 5 4 1 4

( 0 1 ) 0 4 0 5 2 9 3 8 0 0 0 0 1 6

( 2 1 ) J 2 V P F 2 P 4 0 0 4 4 0 D

E N G L I S H

Basic information

3

Installationofpistonsandcylinderliners

3.1Installationanddirectionofinstallation

Youwillndinformationaboutthenominal

pistondiameterandpistonclearanceon

thepistoncrown.Thecombinationofthis

givesthenominaldiameterofthecylinder

bore.Beforeinstallation,thepistonand

cylinderdiametersneedtobemeasured

andcomparedwiththenominaldiameters.

Example

Pistondiameter 79.98mm

Spclearance 0.02mm

Cylinderdiameter 80.00mm

Example Symbol Direction of installation in engine

BMW,MercedesBenz,VW Controlside(oppositeforcetransfer/clutch)

MercedesBenz,Scania SpecialcaseforsomeVengines:Enginecentredirection

Citroën,RenaultAV

Controlside(oppositeforcetransfer/clutch)

“AV”standsfor“avant”=front

Citroën,RenaultAR

Flywheel(forcetransfer/clutch)

“AR”standsfor“arrière”=rear

Peugeot,RenaultV

Flywheel(forcetransfer/clutch)

“V”standsfor“volant”=Flywheel

Peugeot,Vauxhall Flywheel(forcetransfer/clutch)

Citroën,Peugeot,Renault Flywheel(forcetransfer/clutch)

Fiat,Iveco > Flywheel(forcetransfer/clutch)

Vauxhall,Perkins Groove Controlside(oppositeforcetransfer/clutch)

GM,Perkins FRONT Controlside(oppositeforcetransfer/clutch)

Hatz,Liebherr front Controlside(oppositeforcetransfer/clutch)

Deutz,MWM Exhaustair Forair-cooledenginesthedirectionofcoolingair

Nominal piston diameter Trade mark

Installation marking

Art. no.

Measuring window

Batch number

Clearance

Theoverviewbelowliststhesymbolsandtheirmeaningforthedirectionofinstalla-

tionintheengine.

Dependingontheenginemanufacturers,

thesamesymbolscanhavedierent

meanings.

Forpistonswithskirtcoatingwithoutmeasuringwindow,0.01-0.03mmof

layerthicknessstillneedtobededucted

fromthemeasurementtogetthestamped

pistondiameter.

Forpistonswithmeasuringwindow,the

pistondiametercanbedeterminedhere

withoutdeductingthethicknessofthe

skirtcoating.

Flywheel (force transfer/clutch)

Control side

33

7/28/2019 Ko Einbau en Web

http://slidepdf.com/reader/full/ko-einbau-en-web 2/7

B C+ C- C

B C C

Basic information

3.2

Gapdimensionandpistonpositionintopdeadcentre

Piston protrusion or piston recess dimen-

sion in top dead centre for different engine

versions*

BelowthedimensionC,theprotrusion

(markedby+)ortherecess(markedby-)

ofthepistoninthetopdeadcentreisto

beunderstoodinrelationtothecylinderblocksealingface.Thesealthicknessor

geometricalshapesofthecylinderhead

arenottakenintoaccount.

Forengineswithwetcylinderliner,the

protrusionorrecessofthepistonisalso

measuredinrelationtothecylinderblock

face.

Aprotrusionofthecylinderlineroran

existinglandedgeisnottakeninto

account.

Forair-cooledcylinders,dimensionCrefers

tothedistancebetweenpistoncrownand

theseatofthecylinderheadontheair

cooledcylinder.

Anodised piston crowns

Forpistonswithanodisedpistoncrown,

thecrownforsettingthepistonprotrusion

mustnotbescrewedo.

Thepistonscanberecognisedbythegrey

colourofthecrownsurface.

Note

Forsettingthepistonprotrusion,pistons

withreducedcompressionheightare

alsoavailableinadditiontothestandard

pistons.

Gap dimension*Thegapdimension(B)istheprotrusionor

recessofthepistoninthetopdeadcentre

inrelationtothesealingfaceofthecyl-

inderblock.Thethicknessofthecylinder

headgasketandapossiblerecessinthe

cylinderheadaretakenintoaccountfor

measuring.Thisdimensionisalsoknown

as“leaddimension”.

* see pictogram line un-

der item 1 “Instructions

for using the catalogue”

34

7/28/2019 Ko Einbau en Web

http://slidepdf.com/reader/full/ko-einbau-en-web 3/7

B A B

E N G L I S H

Basic information

3.3

Installationofcylinderliners

Whenreplacingcylinderliners,someprep-

arationworkneedstobeperformedandcriticalissuesmustbechecked.Oncethe

oldcylinderlinersareremovedandbefore

thenewcylinderlinersareinserted,the

engineblockmustbethoroughlycleaned.

Particularlyforengineblockswithwet

cylinderliners,allcoolantresiduesand

fragmentsofgasketsaretoberemoved

fromtheareaofthecylinderlinerxture.

Installation of wet cylinder liners

1.Firstofallthecylinderlinersare

insertedwithoutsealingrings.Thisway

itischeckedwhetherthecylinderliners

canbeinsertedeasilyandwithoutjam-

ming.Ajammingofthecylinderlinerin

theborealwaysresultsindeformationof

thecylinderbore.Furthermoreitneedsto

becheckedwhetherthelinerangerests

completelyushandplane-parallelinthe

engineblock.Forthispurposethecontact

Particularcareneedstobetakenforall

contactsurfaces.Theymustbepreparedso

thattheyaremetallicallyclean,completely

levelandnon-corroded.

Hardtoolslikescrapers,cuttersetc.must

notbeusedduetotheriskofdamaging

thesesurfaces.Worncylinderblockfacesandlinerange

counterboresmustbereworked.Ifthe

diametersofthecylinderlinerboreexceed

themaximumpermissibledimension,

thesurfacesareseverelycorrodedorare

distorted,theengineblockmustbedrilled

openaccordingly.

Thecylinderlinersmustthenbeinserted

withoutsideoversizeand/orlinerswith

oversizedange.Cylinderlinerswith

dierentoversizesareavailableintheKS

deliveryprogramformanyenginetypes.

Correct fange seat Liner protrusion B

surfacescanbecoatedwithsurfacepaste

tocheckthewearpatternthisway.Ifthe

wearpatternisnotimmaculate,theange

counterboreintheengineblockneedsto

bereworked.

2.Thentheamountofprotrusionofthe

cylinderlinersmustbechecked.Ifcylinder

linersareconcernedwhereametalseal

(Tombak,stainlesssteel)isusedforseal-

ingothelinerange,itmustbeinserted

formeasuringtheangeprotrusion.Ifthe

amountofprotrusionistoolittle,thismust

becorrectedbyusingcylinderlinerswith

oversizedangeheightorsteelshims.If

theamountofangeprotrusioniswrongor

iftheangeseatisuneven,thesealofthe

combustionchamberisnotguaranteed.

Thiscanresultincylinderdistortionsand

linerangefractures.

3.Fornalinstallationofthecylinder

linersincludingElastomerseals,lubricant

mustbeusedforeasierandsaferinstalla-

tionofthecylinderliners.Thelubricantor

assemblypasteisappliedtothesurfaces

ofthecylinderlinerandengineblock,

acrosswhichthesealingsringsmustslide

duringassembly.TheElastomerseals

themselvesdonotneedanylubricant.The

cylinderlinersmustbeinsertedslowlyby

handandsecuredinthesystem.Theymust

notbeinsertedwithforceorhardblowsof

thehammer.

4.Oncethecylinderlinersareinstalled,

thecylinderboresmustbecheckedfor

roundnessandconstrictionsinthearea

ofthesealingringswithaboremeasuring

devicewithdialgauge.

Attention:

Liquidsealantsandsealingpastemustnot

beusedwheninstallingwetcylinderliners.

Areliabletofthecylinderlinerscannot

beguaranteedinthiscase.Furthermore,

theElastomersealscannotmeettheirseal-

ingfunctionifthesealingringgroovesare

lledadditionallywithsealant.Themetal

discsthatmightbesuppliedwiththecylin-

derlinersandthataremadeofTombakor

stainlesssteelareseals.Themetalseals

mustbeinsertedbetweenengineblock

andcylinderlinerinanycase.Themetal

sealsarenotsuitedtoconguringtheliner

protrusion.Multiplesealsmustnotbe

placedandinstalledontopofeachother.

35

The fange seat A must be plane-parallel.

7/28/2019 Ko Einbau en Web

http://slidepdf.com/reader/full/ko-einbau-en-web 4/7

B

D

C

Basic information

B

D

C

Installation of dry cylinder liners in

“Slipfit” version ( “Finished”)

1.Theselinersarenishedontheinternaldiameterandcanberemovedandre-

installedmanuallyorwithsuitabletools.

Theengineblockdoesnotneedtobe

removedfromthevehicleforthispurpose.

Installation of dry cylinder liners in

“Pressfit” version (“Semi-finished” )1.Thesecylinderlinersareonlynished

ontheexternaldiameter.

Theinsidediameterisonlycoarselypre-

nished.Toreplacethesecylinderliners,

theengineblockmustberemovedfromthe

vehicleandcompletelydisassembled.

2.Toremovethecylinderlinerstheseare

eitherdestroyedwithachiselorsimilar

toolordrilledoutoftheengineblock.

Furtherpreparation/checkingoftheengine

blockisthesameasforthe“Slip-t”version.

3.Asthesecylinderlinershaveapress

ttingintheengineblock,theymustbe

pressedintotheengineblockbyusinga

press.

Thepressttingisseveralhundredth

millimetresandisdeterminedbythe

specicationsoftheenginemanufacturer.

Beforepressingin,thecylinderlinersmust

becoatedwithasuitable,thinlubricanton

theexternaldiameter.Thecylinderliners

shouldbepressedintotheengineblockin

onestepwithoutinterruptionifpossible.

Aninterruptionofthepress-inproce-

dureresultsinlargebreakawaytorques

whenpressingcontinuesandfrequently

B = Liner protrusionC = Chamfer D = Radius

For“Slipt“cylinderlinerstheclearanceis

0.00-0.015mm.If0.015mmisexceeded,

anoversizelinermustbeused.

inbreakingofthecylinderliners.Ifthe

press-inprocedurecannotbeperformedinonestepduetoamissingpressstroke,the

shortpartthatismissingmustbecovered

atthestartofthepressstrokeandthelast

parttakingfulladvantageoftheavailable

pressstroke.

Thepressureplatewhichisinserted

betweenpressstampandcylinderliner

mustbethickenoughsothatitdoesnot

breakduringpressing.

Animpressionofthelinerangecanbe

preventedthisway.

Installation dimensions for “Pressfit”

cylinder liners

Cylinder diameter 50 - 80 mm 80 - 120 mm 120 - 180 mm

Presst 0.045mm-·0.070mm 0.055 - 0.080 mm 0.065 - 0.090 mm

2.Beforeinsertingthecylinderliner,the

cylinderlinercounterboremustbechecked

forroundnessanddistortion.Thebevelled

edge(C)inthehousingmustcorrespondto

therounding(D)onthecylinderliner.

3.Beforeinsertingthecylinderliners,thecylinderboresmustbecheckedforround-

nessordeformations.Forthesecylinder

liners,thelinerprotrusiondimension(B)

speciedbythemanufacturermustbe

adheredto.Thisisimportanttoensure

thatthelinersarepressedrmlydown

ontotheirseatduringoperationandare

anchoredcorrectlyintheengineblock.

Insufficientprotrusionresultsinsealing

problemsandformationofcracksonthe

liners.

4.Asthecylinderlinersdeformslightly

duringpressingin,theymuststillbenishedtottherequiredcylinderend

dimensionthroughdrillingandhoning.

Duetothepresstting,thesecylinder

linersdonotcompulsorilyrequirealiner

angeanddogenerallynothavealiner

protrusion(B).Oncethecylinderlinersare

pressedin,thecylinderblockfacemustbe

fullyreworkedonce,sothatthecylinder

linersdonotprotrudeovertheengine

blockface.

Thespecicationsarereferencevalues.Thespeciedscalesoftheenginemanufacturerare

decisiveinthiscase.

36

7/28/2019 Ko Einbau en Web

http://slidepdf.com/reader/full/ko-einbau-en-web 5/7

E N G L I S H

Basic information

3.4

Fittingthepistons

Assembly of pistons and connecting rods

Beforeinstallingtheconnectingrodsthey

needtobecheckedfordistortionand

twistingwithasuitabletestinginstrument.

Positionthepistonandtheconnectingrod

accordingtotheinstallationdirection.The

oiledpiniscarefullyinsertedintothepin

boresofthepistonandintotheconnecting

rodeyeoftheconnectingrod.Forpistons

withtightlytolerancedpinbore,insertion

ofthepiniseasierifthepistonisheatedto

approx.40°C.

For swimming pins

Retainerringsaresuppliedforxationof

thepin.

Usedretainerringsmustnolongerbe

used.Topreventlastingdeformations,

theretainerringsmustnotbepressed

togethertoohard.

Assembly of connecting rod with fixed pin

Theboreintheconnectingrodeyemust

haveapressttothepin.Forassembly

theconnectingrodistobeheatedto280-

320°C(noopename!).Afterwardsquickly

insertthewelloiledandcoldpinintothe

connectingrodeye.Toensurecorrectposi-

tioningofthepinintheconnectingrod,a

devicewithstoppinistobeused.

Whethertheringshavesafelylockedinto

thegroovescanbecheckedbyslightly

turningthem.Thejointoftheretention

mustalwaysbeindirectionofthepiston

stroke.

37

7/28/2019 Ko Einbau en Web

http://slidepdf.com/reader/full/ko-einbau-en-web 6/7

Basic information

Checking the piston rings

Checkwhethertheringscanbefreely

(turned)rotatedintheringgrooves.

Forpistonringsmarkedwith“TOP”,the

markingmustpointtothepistoncrown.

Thisensurestheintendedfunctioniswork-

ing.

Spiral expander oil control rings

Thejointendsofthespiralexpander

shouldalwaysbeexactlyoppositethering

jointforspiralexpanderrings.Forspiral

expanderswithTeonsheath,thesheath

restsagainsttheringjoint.

Inaddition,forspiralexpanderringswith

locatinghookitisimportantthatthelocat-

inghookislockedintotheoilslot.

3-part steel rail oil control rings

Duringtransportthespiralendsare

untightenedandcansliponeabove

another.Thepositionmightneedtobe

correctedbeforeinstallation.Bothcolour

markingsatthespiralendsmustbevis-

ible.Iftheyarenotvisible,thespiralhas

overlappedandtheringisnotworking.

Theringjointsofthe3-partoilcontrol

ring(thetwosteelrailsandtheexpander

spring)mustbeturnedagainsteachother

by120°eachbeforeinstallation.

Oil slot Locating hook

Spiral expander ring with locating hook

red colour mark green colour mark

Installationrecommendation

overlapped joint

wrong:

correct:

38

7/28/2019 Ko Einbau en Web

http://slidepdf.com/reader/full/ko-einbau-en-web 7/7

E N G L I S H

Basic information

Inserting the piston into the cylinder liner

Cleanthecylinderblockthoroughly.Make

surethatallglidingsurfacesarefreefrom

dirtandwelloiled.Pressthepistonrings

togetherwithasqueezertoenablethe

pistonglidingintothecylinderlinerwith-

outresistance.ForDieselenginesmeasurethegapdimensionorpiston'samountof

protrusionandalwaysadheretomanufac-

turer'sspecications.

3.5

Running-innotes

Theenginemustberuninontheroadif

notestrigisavailableforimplementinga

denedrun-inroutine.

•Thevehicleshouldnotbefullyladen.

•Runtheengineatconstantlychanging

speedlevelsnotexceeding2/3ofthe

maximumenginespeed.

•Shiftupbrisklywhilstdriving

andavoidunderrevving.

•Avoidmaximumgearspeeds.

•Avoidlengthyuphilldriving

(excessiveload).

Further advice

• Keepaconstantcheckontheoillevel

duringtherun-inphase.

Theoilconsumptioncanbeincreased.

Itisadvisabletochecktheoillevel

every50to100kmandtopupwithoilif

necessary.Ifthereisanoticeabledropin

theoillevelonthedipstick,continueto

monitoratshorterintervals.

•Donotoverlltheenginewithoil.

•Oilchangeafter1000km–Anoillter

changeisimportanthere.Thedirtand

abrasionfromrun-inhastoberemoved

fromtheengine.

•Avoidlengthydownhilldriving

(insufficientloadandundesirable

overrun).

•Donotuseenginebrakingsystems.

•Donotdriveonmotorwaysorattop

speed.

• Avoiddrivingincongestedtraffic.Driving

onopenroadsandinfree-owingurban

trafficisbest.Butnourbantrafficwith

extremelyhotoutsidetemperaturesand

withfrequentstopsattrafficlightsand

waitingtimes.

39