QUENCH-12 test First results

Transcript of QUENCH-12 test First results

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 1

QUENCH-12 testFirst results

J. Stuckert, J. Moch, L. Sepold, U. Stegmaier, L. Steinbock, M. Steinbrück

Institute for Materials Research IIIInstitute for Materials Research I

Forschungszentrum KarlsruhePostfach 3640. 76021 Karlsruhe. Germany

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 2

Objectives of the QUENCH-12 test

• investigation of the effects of VVER materials and bundle geometry on core reflood

• comparison with the PWR bundle on the base of repeat of the test QUENCH-06 (ISP-45) scenario

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 3

Removable corner rod. Zr1%Nb. ø6 mm

Heated fuel rod simulator (18 rods)cladding Zr1%Nb. ø9.15/7.73 mm;W-heater. ø4mm;pellet ZrO2. ø7.57/4.15mm.

Instrumented tube.Zr1%Nb. ø5.75 mm

Unheated fuel rod simulator (13 rods)cladding Zr1%Nb. ø9.13/7.73mm;central thermocouple;ZrO2 pellet. ø7.57/2.5 mm.

Shroud tube Zr2.5%Nb ø 88.0/83.5mm

Thermal insulation: ZrO2 fibre;thickness 37 mm

QUENCH-12: Cross section of the VVER-column.

pitch 12.75

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 4

Comparison of geometrical parameters of the QUENCH-12 bundlewith the QUENCH-06 bundle:

1) coolant channel area relationship Q12/Q06 = 1.09 ⇒ the fluid flow rate should be 9% higher for the Q12 bundle than for the Q06 bundle to provide the same flow velocity

2) metallic surface relationship Q12/Q06 = 1.22 ⇒ higher chemical energy production for the VVER bundle due to exothermic steam-metal reaction;

3) bundle material mass relationship Q12/Q06 ~0.97 ⇒ the electrical power for the VVER bundle should be lower than for the Q06 bundle.

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 5

Pretest modelling support:

1. SCDAP/SIM simulations: J. Birchley, T. Haste, Paul Scherer

Institute, Switzerland.2. ICARE/CATHARE simulations: A. Volchek, Yu. Zvonarev, Kurchatov Institute, Mosccow, with support from IRSN Cadarache).

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 6

350

400

450

500

550

600

650

700

750

800

-1000 -500 0 500 1000 1500 2000 2500 3000 3500 4000Time, s

Tem

pera

ture

, °C

0

1

2

3

4

5

6

Pow

er, k

W

TFC 1/13 TFC 14/4/13 TFSH 2/2/13 TFSU 17/3/13 TSH 13/90 TIT A/13 TFC 1/12 TIT C/12 T 511 inlet P_el.

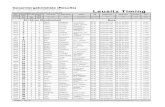

Preliminary test with VVER bundle (without reflood)to supply the tuning parameter for the pretest calculations to QUENCH-12.

TC readings for elevations 850 mm and 950 mm: significant radial gradient for low temperatures.

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 7

1st

rod~1.5 h ~1 h

~600°C

~3400 s ~2600 s

Ar, 3.3 g/s

Superheated steam (510°C), 3.3 g/s

TFS=1800°C

Water, 48 g/s(~400 s)

2nd

rod1550°C

~3.5 kW

~10 kW

~ 4 kW

3.3 mg/s

m

Pel

H2

.

~9 kW

1200°C

16.6 kW

T

60 s beforetransient

~1250 s

Time

stabilisation heat-up pre-oxidation quenchtransient

Time scheme of the QUENCH-12 test

3rd

rod

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 8

3

5

7

9

11

13

15

17

19

21

0 1000 2000 3000 4000 5000 6000 7000 8000Time, s

Pow

er, k

W

300

500

700

900

1100

1300

1500

1700

1900

2100

Tem

pera

ture

, K

P_el_Q6 P_el_Q12 TIT A/13_Q6 TFC 1/13_Q12

Comparison of temperature and power profiles for QUENCH-12 and QUECH-06.

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 9

300

500

700

900

1100

1300

1500

1700

1900

2100

0 1000 2000 3000 4000 5000 6000 7000 8000

Time, s

Tem

pera

ture

, K

TFSU 31/5/17 TFC 13/3/16 TFSH 5/2/15 TFC 9/3/14 TFC 1/13 TFSH 3/2/12 TFSH 23/5/11 TFSU 1/9 TFSH 5/2/7 TFSH 24/5/4 TFSH 4/2/1

950 mm1050 mm

850 mm1150 mm

750 mm1250 mm

550 mm 350 mm

1350 mm

50 mm

-250 mm

QUENCH-12: selected reading of the bundle thermocouples.

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 10

-400

-200

0

200

400

600

800

1000

1200

1400

1600

500 700 900 1100 1300 1500 1700 1900 2100Temperature, K

Elev

atio

n, m

m

5965 s (1st corn. rod - preoxid.) 7150 s (2nd corn. rod) 7265 s (transient end)

QUENCH-12: axial temperature profiles during pre-oxidation and transient phases

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 11

QUENCH-12, before quench phase: failure of unheated rods, heated rods and shroud

1

1,2

1,4

1,6

1,8

2

2,2

2,4

2,6

7150 7200 7250 7300 7350 7400Time, s

Pres

sure

, bar

0,00

0,05

0,10

0,15

0,20

0,25

0,30

0,35

0,40

Con

cent

ratio

n, %

P 406 (shroud) P 901 (unheated rods) P 411 (heated rods)He (MS) Kr (MS*100)

quench

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 12

0

5

10

15

20

25

30

35

40

45

50

7200 7300 7400 7500 7600 7700 7800 7900Time, s

Wat

er in

ject

ion

rate

, g/s

-400

-200

0

200

400

600

800

1000

1200

1400

1600

Wat

er le

vel,

mm

Fm 104 (pump rate) L 501 (water level)

QUENCH-12, quench phase: water injection

fastwater

injection(4 l during 5 s)

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 13

300

500

700

900

1100

1300

1500

1700

1900

2100

7100 7150 7200 7250 7300 7350 7400 7450 7500 7550 7600Time, s

Tem

pera

ture

, K

TFSU 31/5/17 TFC 13/3/16 TFC 16/4/15 TFC 15/3/14 TFC 14/4/13 TFC 1/13 TFSH 3/2/12 TFSH 7/2/11 TFSU 16/4/10 TFSH 30/5/9 TFSU 15/3/6 TFSU 13/3/5 TFSH 24/5/4 TFSH 4/2/1

QUENCH-12, quench phase: selected reading of the bundle thermocouples.Temporary sharp decrease of the cladding surface temperature as reaction on the fog from the water fast

injection system. Pellet internal thermocouples show smooth cooling of the bundle during ~350 s.

quench

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 14

300

500

700

900

1100

1300

1500

1700

1900

2100

2300

2500

7100 7150 7200 7250 7300 7350 7400 7450 7500 7550 7600Time, s

Tem

pera

ture

, K

TSH 16/180 TSH 15/0 TSH 14/90 TSH 13/90 TSH 12/0 TSH 11/0 TSH 10/90 TSH 9/180 TSH 8/270 TSH 7/0 TSH 4/90 TSH 1/0

QUENCH-12, quench phase: selected reading of the shroud thermocouples.Short temperature escalation at elevations 950 mm – 1250 mm.

50 mm

-250 mm

350 mm

850 mm

950 mm 1050 mm

1150 mm1250 mm

quench

β-Zr melting

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 15

neutronography (M. Große)shows the deep hole with

irregular diameter

melt formation in bundle at the breakposition of the corner rod B (850 mm)upper part of the rod B:

is the absent central partthe melted β-Zr?

QUENCH-12: melt formation at 850 mmon the position of withdrawn corner rod B.

ZrO2 layer~500 µm

α-Zr(O) layer~650 µm

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 16

corner rod B after pre-test (800 °C, oxide layer thickness less of 5 µm)

corner rods D, F, B after pre-test: spalling of the outer skin of oxide layer.D – withdrawn after pre-oxidation,

F – withdrawn before reflood,B – withdrawn after test.

D

F

B

QUENCH-12: withdrawn corner rods

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 17

QUENCH-12: axial sections of different ZrO2 spalling intensity on withdrawn corner rods

Bafter test

Fbeforereflood

Dafter

preoxidation

F D F D

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 18

side view from corner rod Bon the top of the first spacer (-150 mm)

camera in position of corner rod D at 650 mm:spalled oxide scales at shroud and cladding

QUENCH-12, videoscope analysis: intensive oxide scale spalling inside of bundle

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 19

epoxy

ZrO2 scale

QUENCH-12: laminated structure of spalled oxide scales

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 20

QUENCH-12, videoscope analysis : cladding cracks development

cross crack at 600 mm (rod D) longitudinal crack at 650 mm (rod F)

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 21

bundle at angle position of 180°

upper part of the shroud braked offfrom the bundle during dismounting

(angle position of 180°)

instrumentedcorner rod E

instrumentedcorner rod C

cross cracksat heated rods

QUENCH-12: bundle posttest view after dismantling of zirconia fiber insulation

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 22

0

5

10

15

20

25

30

35

40

550 650 750 850 950 1050 1150Elevation, mm

Hyd

roge

n, a

t%

corner rod D (preoxid.) corner rod F (tansient) corner rod B (end of test)

QUENCH-12: hydrogen uptake by corner rods/results of neutronography/

highest bundletemperature

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 23

0,0

0,5

1,0

1,5

2,0

2,5

3,0

7000 7050 7100 7150 7200 7250 7300 7350 7400 7450 7500Time, s

Rat

e, m

g/s

0

10

20

30

40

50

60

Inte

gral

, g

rate_H2_Q12 rate_H2_Q6 intl_H2_Q12 intl_H2_Q6

Comparison of hydrogen release during QUENCH-12 and QUECH-06.

QUENCH-12: H2 production before reflood 34 g, during reflood 24 gQUENCH-06: H2 production before reflood 32 g, during reflood 4 g

refloodQUENCH-06

reflood QUENCH-12

Forschungszentrum Karlsruhein der Helmholtz-Gemeinschaft

J. Stuckert, FZK/IMF-III 12 th QUENCH Workshop. October 24-26. 2006 24

SUMMARY

• The QUENCH-12 experiment investigated the effects of VVER materials and bundle geometry on core reflood, in comparison with test QUENCH-06 (ISP-45) with Western PWR geometry.

• The preliminary test at the maximum temperature 800°C was performed. The corresponding oxidation was negligible: less of 5 µm. The results of this test were used to fine attenuation of the pretest modelling.

• The electrical power changing during the test corresponds completely to calculated values up to reflood phase. The temperature history during preoxidation is very similar to the QUENCH-06 temperature history.

• Two corner rods were withdrawn at the end of preoxidation and transient phases correspondingly. The surface of the rods shows intensive traces of the break-away effect influence. Many oxide scales with thickness about 100 µm were spalled during withdrawn.

• Following reflood initiation, a moderate temperature excursion of ca. 50 K was observed, over a longer period than in QUENCH-06. The temperatures at elevations between 850 mm and 1050 mm exceeded the melting temperature of β-Zr.

• The total hydrogen production was 58 g (for QUENCH-06: 36 g), during the reflood was released 24 g hydrogen (for QUENCH-06: 4 g).