Anwendungen der Simulation im Bereich additive Fertigung

Transcript of Anwendungen der Simulation im Bereich additive Fertigung

© CADFEM (Suisse) AG, 2019

Vom Design zum DruckAnwendungen der Simulation im Bereich additive Fertigung

Dr. Manfred Maurer

CADFEM (Suisse) AG

© CADFEM (Suisse) AG, 2019

Simulation ist mehr

als Software

Produkte, Service und Wissen

bieten wir deshalb aus einer Hand

© CADFEM (Suisse) AG, 2019

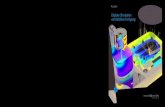

Metal AM – Powder Bed Fusion

ScannerLaser

Powder delivery piston

Fabrication powder bed

Fabrication piston

PowderDeliverysystem

Object beingfabricated

Roller

5

© CADFEM (Suisse) AG, 2019

The AM Promise

1. Impossible to Manufacture

2. Lightweighting

3. Part Consolidation

4. Multifunctional Designs

5. Distributed Production

6. New Material Properties

7. Replacement Parts

8. Customization

9. …

6

© CADFEM (Suisse) AG, 2019

Current AM Workflow

DesignBuild job

preparationPrint Measure

Expensive iterations due to failed prints

Recoatercollision

Supports detach Deformation of partCracks in part

7

A.D. Rollet et al.

Porosity in part

© CADFEM (Suisse) AG, 2019

Ideal AM Workflow

DesignBuild job

preparationPrint Measure

Process

Simulation

Compensated geometryTemperature DistortionsResidual stresses

9

© CADFEM (Suisse) AG, 2019

Design for AM

• Need to rethink design!

• Cannot take existing part design and expect AM to be cost competitive

• Design to the strengths (and weaknesses) of the process

• Take advantage of greater design freedom with topology optimization

11

© CADFEM (Suisse) AG, 2019

Additive Print

• For the machine operators/manufacturing engineers – no simulation experience necessary

• Quick print evaluation

• Distortion and stresses

• Optimize orientation and support structures

• Compensate for distortion

• Detect blade crash

14

© CADFEM (Suisse) AG, 2019

Distortion

Measured

surface

CMM data is provided by Dr. Edward De Meter Pennsylvania State University

Penn State GE Bracket (assumed strain based)

15

© CADFEM (Suisse) AG, 2019

Example – Heat Exchanger

Distortion often happens at the top of aligned holes

• Can simulation predict this phenomenon?

• What level of simulation is needed?

Thin walled complex parts can be simulated

16

© CADFEM (Suisse) AG, 2019

Distortion Compensation

Compensated GeometryOriginal Geometry

17

stl stlsimulation simulationreal print real print

© CADFEM (Suisse) AG, 2019

Example – Conformal Cooling

• Conformal cooling allows for optimizing cooling and flow rates by allowing for channels not manufacturable via conventional methods

• However, it is usually important that there are no support structures inside the cooling channels

• Powder removal from small channels can also be an issue

• Run without supports direct to build plate

18

© CADFEM (Suisse) AG, 2019

Example – Conformal Cooling

• Variable wall thicknesses result in uneven part shrinkage

• Passages and the cross section are no longer even or circular

19

© CADFEM (Suisse) AG, 2019

Example – Conformal Cooling

Use compensated geometry STL file plus additional machining stock on exterior and base

20

© CADFEM (Suisse) AG, 2019

Blade Crash Prediction

Predicting distortion during the build process can help identify potential blade crashes

21

© CADFEM (Suisse) AG, 2019

Example – Support Angle and Distortion

Impeller geometry with a 30° support angle setting

22

© CADFEM (Suisse) AG, 2019

Example – Support Angle and Distortion

Impeller geometry with a 45° support angle setting

23

© CADFEM (Suisse) AG, 2019

Support Optimization

Based on stresses, define support sizing

Courtesy Tim Gornet, University of Louisville

Supports Generated by Magics Optimized Supports

24

© CADFEM (Suisse) AG, 2019

Example – P3 Corner Fitting

• Flight critical legacy die cast component prone to in-service issues

• Four build iterations required to get support structure sufficient to anchor part to baseplate

• Post-production review using Additive Print

• One simulation showed the type of support structure needed for success

• Additive Print auto-generated the correct supports for a successful build

25

© CADFEM (Suisse) AG, 2019

Example – P3 Corner Fitting

Support Failure Prediction

• Prediction of support failure for default supports show excellent correlation to experimental results

• Strengthened supports were also correctly predicted to fail

Default Support

Failure Prediction

Strengthened Support

Failure Prediction

26

© CADFEM (Suisse) AG, 2019

Porosity Defect Predictions (GE P&W Results )

0.00%

5.00%

10.00%

15.00%

20.00%

25.00%

30.00%

850 1050 1250 1450 1650 1850 2050 2250 2450 2650

Po

rosi

ty P

erc

en

tage

Laser Speed (mm/s)

Calculated Porosity (number density) vs. Image Analysis Result (385W)

Simulation Results

Experimental Results

27

© CADFEM (Suisse) AG, 2019

Machine Parameters

Porosity Prediction

Micro structure analysis

Material Selection

Thermal HistoryTopology Optimization CAD clean up Part Validation

Lattice Optimization

Heat Treatment

Nesting

Support Generation

Support Optimization

Orientation Optimization

Lattice Validation

Intuitive CAD

Re-buildingAdvanced Top Op

Mfg. constraints

5 types AM

Simulation Models

Auto Distortion Compensation

AM Validation

Structural Validation

Design for AM Validation Build SetupProcess

SimulationQualification

Data Acquisition and

Certification Generative Design

29

© CADFEM (Suisse) AG, 2019 31

Technologietag bei Sauber Engineering:

Simulation als Innovationstreiber in der

additiven Fertigung

14.11.2019, ab 13:15

https://t1p.de/AMtechtag

© CADFEM (Suisse) AG, 2019

Thank you for your attention!

Dr. sc. (ETH) Manfred Maurer

+41 (0)52 368 01 39

32