Schopfer Et Al IRMMS 2009 Repository

Transcript of Schopfer Et Al IRMMS 2009 Repository

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 1/42

Provided by the author(s) and University College Dublin Library in accordance with publisher policies. Please

cite the published version when available.

Downloaded 2014-03-18T18:45:52Z

TitleThe impact of porosity and crack density on the elasticity,strength and friction of cohesive granular materials : insightsfrom DEM modelling

Author(s)Schöpfer, Martin P. J.; Abe, Steffen; Childs, Conrad; Walsh,John J.

PublicationDate

2009-02

Publicationinformation

International Journal of Rock Mechanics and Mining Sciences,46 (2): 250-261

Publisher Elsevier

Link topublisher's

version

http://dx.doi.org/10.1016/j.ijrmms.2008.03.009

This item'srecord/moreinformation

http://hdl.handle.net/10197/3027

Rights

This is the author’s version of a work that was accepted forpublication in International Journal of Rock Mechanics andMining Sciences. Changes resulting from the publishingprocess, such as peer review, editing, corrections, structuralformatting, and other quality control mechanisms may not bereflected in this document. Changes may have been made tothis work since it was submitted for publication. A definitiveversion was subsequently published in International Journal of Rock Mechanics and Mining Sciences Volume 46, Issue 2,February 2009, Pages 250-261DOI#:10.1016/j.ijrmms.2008.03.009.

DOI http://dx.doi.org/10.1016/j.ijrmms.2008.03.009

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 2/42

Some rights reserved. For more information, please see the item record link above.

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 3/42

The impact of porosity and crack density on the elasticity,1

strength and friction of cohesive granular materials: Insights2

from DEM modelling3

Martin P.J. Schöpfer *,1, Steffen Abe+,2, Conrad Childs1 and John J. Walsh1 4

1Fault Analysis Group, School of Geological Sciences, University College Dublin,5

Belfield, Dublin 4, Ireland.6

2 Seismology & Computational Rock Physics Laboratory, School of Geological7

Sciences, University College Dublin, Belfield, Dublin 4, Ireland.8

9

Abstract10

Empirical rock properties and continuum mechanics provide a basis for defining11

relationships between a variety of mechanical properties, such as strength, friction12

angle, Young’s modulus, Poisson’s ratio, on the one hand and both porosity and crack13

density, on the other. This study uses the Discrete Element Method (DEM), in which14

rock is represented by bonded, spherical particles, to investigate the dependence of15

elasticity, strength and friction angle on porosity and crack density. A series of16

confined triaxial extension and compression tests was performed on samples that were17

generated with different particle packing methods, characterised by differing particle18

size distributions and porosities, and with different proportions of pre-existing cracks,19

or uncemented grain contacts, modelled as non-bonded contacts. The 3D DEM model20

results demonstrate that the friction angle decreases (almost) linearly with increasing21

* Corresponding author. Tel.: +353 1 7162611; fax: +353 1 7162607

E-mail address: [email protected]

+ Present address: Geologie-Endogene Dynamik, RWTH Aachen University, Aachen, Germany

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 4/42

porosity and is independent of particle size distribution. Young’s modulus, strength22

and the ratio of unconfined compressive strength to tensile strength (UCS/T) also23

decrease with increasing porosity, whereas Poisson’s ratio is (almost) porosity24

independent. The pre-eminent control on UCS/T is however the proportion of bonded25

contacts, suggesting that UCS/T increases with increasing crack density. Young’s26

modulus and strength decrease, while Poisson’s ratio increases with increasing crack27

density. The modelling results replicate a wide range of empirical relationships28

observed in rocks and underpin improved methods for the calibration of DEM model29

materials.30

31

Keywords: Discrete Element Method; Particle Flow Code; Porosity; Friction; Failure32

envelope;33

34

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 5/42

1 Introduction35

Knowledge of the mechanical properties of rocks is fundamental for both Earth36

scientists and engineers. Failure envelopes and elastic parameters are crucial for37

modelling a wide range of geomechanical problems, including wellbore failure, slope38

stabilities and the stability of underground excavations [1]. Rock properties are39

obtained from in-situ tests and more commonly in the laboratory from samples that40

are loaded using stress and/or displacement controlled experiments. These tests have41

given many insights into the behaviour of rock and have shown, for example, that the42

elastic parameters and strength depend on porosity and cement content, though the43

details of these dependencies are also partly controlled by mineral composition (e.g.44

carbonate vs siliciclastic rocks; [2,3]). Obtaining core samples from depth for45

laboratory testing is both time-consuming and expensive. Hence rock physical46

properties are often estimated using empirical relations, such as the correlation47

between Young’s modulus and sonic velocity, or that between unconfined48

compressive strength and porosity [4]. Rock is, however, a heterogeneous material49

and even multiple samples obtained from a single slab of rock can exhibit significant50

compositional variability and hence mechanical behaviour [3]. Therefore some of the51

above mentioned empirical rock property relations are poorly constrained. One of the52

principal aims of this work is to investigate these empirical property relations in53

numerical rock analogues where the effects of compositional heterogeneity can be54

isolated.55

Numerical modelling offers a new avenue to better understand material56

property relations. An advantage of numerical modelling is that the user can examine57

systematically the effect of varying individual input parameters while keeping all58

other parameters constant; this is rarely possible with laboratory measurement. The59

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 6/42

Discrete Element Method (DEM), where rock is represented as an assemblage of60

particles (spheres, ellipsoids, blocks) that interact with each other, is ideal for61

investigating mechanical property relations since the user predefines microproperties62

(particle and cement properties) and determines macroproperties (elastic and strength63

parameters) using numerical lab experiments [5]. The mechanical behaviour of the64

model material is not predefined, as in continuum approaches, but emerges from the65

interaction of particles and cement [6].66

The aim of this study is to investigate the impact of particle size distribution,67

porosity and cement content (i.e. proportion of bonded contacts) on the mechanical68

properties (elasticity, strength, ratio of unconfined compressive strength to tensile69

strength and friction angle) of DEM model materials in 3D. In the next section we70

provide a brief review of rock property relations which are relevant for this study. In71

the following sections we describe the results of the various numerical mechanical72

experiments conducted on samples generated using a range different packing methods73

and compare the observed failure envelopes, failure criteria and rock mechanical74

property relations (cement content, porosity) with those of rocks.75

76

2 Rock property relations and failure envelopes77

In this study we numerically investigate relations between porosity, cement content78

and rock mechanical properties. Here we summarise the most important empirical79

relations obtained from lab experiments (see Fig. 1), which provide the essential80

backdrop to the numerical modelling presented in Section 4.81

Probably the most commonly used failure criterion for rock is the Coulomb82

criterion, which, expressed in terms of the principal stresses σ 1 and σ 3 (σ 1 > σ 3 and83

compressive stresses positive throughout this paper), is written as84

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 7/42

85

)2/45(tanUCS 2

31 iϕ σ σ +°+= , (1)86

87

where UCS is the unconfined compressive strength and ϕ i is the angle of88

internal friction, the tangent of which is called the coefficient of internal friction µ i 89

[1]. Experimental data and theoretical models [7] suggest, however, that a linear90

failure criterion is only valid over a limited range of confining pressures and that a91

non-linear failure envelope concave towards the minimum principal stress axis (in a92

σ 1 vs σ 3 plot) may prove to be the rule rather the exception [2]. An additional93

limitation of both linear and non-linear failure criteria is that they are often94

independent of the intermediate principal stress, σ 2 (Mohr criteria), whereas data from95

polyaxial tests suggests that many rock types exhibit a σ 2 dependence of strength96

[3,8]. Consequently peak stress data and associated failure envelopes obtained from97

triaxial extension and triaxial compression tests exhibit a mismatch, where the former98

plots above the latter in a σ 1 vs σ 3 plot (Fig. 1a). Under some circumstances this99

mismatch can be eliminated by using a criterion that takes the impact of σ 2 into100

account (Fig. 1b). Finally very few experimental data exist within the tensile field (σ 3 101

< 0; Fig. 1a) to define the transition from tensile to shear failure [9], though a102

parabolic failure envelope is most commonly used [10].103

Laboratory tests of rocks indicate that strength, angle of internal friction and104

Young’s modulus decrease with increasing porosity ([4,11-14]; Fig. 1c, d and e).105

Additionally the presence of pre-existing cracks, which have been simulated in the106

laboratory by cyclically heating the rock specimen before loading [15,16], has a107

significant impact on rock mechanical properties (Fig. 1f, g and h). For example,108

strength, the unconfined compressive strength, tensile strength (UCS / T) and Young’s109

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 8/42

modulus decrease with increasing number of heating cycles, which can be related to110

the proportion of non-cohesive grain-grain contacts or crack density.111

112

3 Methods113

3.1

Discrete Element Method114

The results in this paper have been obtained using two different 3D implementations115

of the DEM for spherical particles, the Particle Flow Code (PFC3D; [5,17]) and116

ESyS-Particle (formerly LSMearth; [18,19]). Both codes implement a linear force-117

displacement contact law with Coulomb friction and a particle-particle bond model118

that transmits both force and moment. The majority of the results presented in this119

paper were obtained using PFC3D and the microproperties used are given in Table 1.120

The details of the contact and bond law implementation are slightly different in ESyS-121

Particle, hence only UCS/T ratios are given and compared to those obtained from122

PFC3D.123

As stated earlier, in a DEM model microproperties are defined and the124

macroproperties are obtained using numerical lab experiments, details of which are125

given in Section 3.3. The user therefore varies the microproperties systematically until126

the material exhibits the desired macroscopic mechanical behaviour. There are,127

however, two problems with calibrating DEM models consisting of spherical particles128

to match the response of real rock: (i) The (internal) friction angle of both cohesive129

and non-cohesive materials is typically too low, irrespective of the contact (i.e.130

particle-particle) friction coefficient [20]. Previous attempts to increase the friction131

angle have included modifications to the standard DEM approach including the use of132

clumped [5,21,22] or elliptical particles [23], implementing a rolling resistance [24]133

and explicitly prescribing the macroscopic failure criterion using hybrid methods [25].134

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 9/42

(ii) The ratio of unconfined compressive strength to tensile strength (UCS/T) of DEM135

models of cohesive rock is too low (ca 3-4) compared to rock (> 10), an issue that has136

only recently been addressed in 2D [22,26]. We show later that both the low friction137

angles and low UCS/T ratios obtained in previous studies were partly a consequence138

of the particle packing methods used, which lead to porosities that were too high to139

achieve realistic properties without modifying the standard DEM. In this study, we140

show that different particle packing methods, and hence different particle size141

distribution and model porosity, combined with different proportions of bonded142

contacts can replicate the range of friction angles and UCS/T ratios associated with143

rocks.144

145

3.2 Model Generation and Packing Methods146

There are two end-member methods for generating random dense packing of spheres147

for DEM simulations, constructive and dynamic [27]. For this study we used one148

constructive method, the particle insertion method [28], one dynamic method, the149

specimen genesis procedure widely used by PFC3D users [5], and a hybrid of these150

two (Fig. 2).151

The dynamic specimen genesis procedure used for this study, which is152

described in detail in Ref. 5, is based on a four-step process. (i) Particles with radii153

chosen randomly from a uniform size distribution are randomly generated within a154

volume bound by planar, frictionless walls. (ii) The system is allowed to adjust by155

particle movement under zero friction. (iii) A low isotropic stress is installed by156

modifying the radii of all particles simultaneously. (iv) The radii of particles that have157

less than three contacts are modified iteratively, so that these particles have at least158

three contacts (over 99% of particles have 4 or more contacts in the final model) and159

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 10/42

their mean contact normal force is low in relation to the mean contact force of the160

assembly. Models generated with the dynamic method had a uniform PSD with161

r max/r min of 1.66 (Fig. 3) and a porosity of ~37% (model i in Fig. 2).162

For the particle insertion method ‘seed’ particles are first generated within163

the specimen domain. The specimen is then filled up by iteratively inserting particles164

so that each new particle touches four neighbours. The filling-up of the specimen is165

completed when no further particles can be inserted. The number of particles and the166

final porosity that can be achieved with this method are a function of the predefined167

particle size range (r max/r min). Models generated with the particle insertion method had168

a power-law particle size distribution (PSD) with an exponent of ~3.0 (Fig. 3) and a169

porosity of ~23% if the maximum to minimum particle radius ratio (r max/r min) is 10170

(model ii in Fig. 2).171

Porosities between 23 and 37% were achieved in three different ways (Fig.172

2): (i) systematic deletion of the smallest particles from a power-law PSD model with173

23% porosity (2nd row in Fig. 2), (ii) direct generation of an assembly with power-law174

PSD using r max/r min < 10, and (iii) insertion of particles into a uniform PSD assembly175

with an initial porosity of 37% using the particle insertion method referred to above176

(1st row in Fig. 2). All specimens were rectangular parallelepipeds with a square base177

and a height to width ratio of 2.178

The average coordination numbers (i.e. number of contacts per particle) of179

the models range from 7.3 to 5.8, where the low porosity models have both a greater180

average and a greater range of coordination numbers. The average coordination181

numbers of the different PSD models are almost identical (within 10%) for a given182

porosity, though the range of coordination numbers is greater in the power-law PSD183

models than in the uniform/bimodal PSD models. For example, the greatest184

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 11/42

coordination number in the 23% porosity power-law model is 131, whereas in the185

bimodal model with identical porosity it is 56. The mode of coordination numbers in186

all models is 4 (which is the value for a newly inserted particle in the particle insertion187

method explained above), except in the 37% porosity model with uniform PSD, in188

which the mode is 5. In summary, the average coordination numbers decrease slightly,189

whereas the range of coordination numbers decreases significantly with increasing190

porosity. A possible explanation for the observed relationship between mechanical191

properties and porosity is that the reduction in the number of contacts which192

accompanies an increase in porosity gives rise to an increase in the tortuosity of193

remaining force chains, causing a decrease in Young’s modulus, and an increase in194

the load they transmit causing a decrease in sample strength.195

While the model porosity values cannot be compared directly to those of real196

rocks, which are typically composed of non-spherical grains that can be packed better197

than spheres, and the effect of finite sized cement using bonds was not taken into198

account in the porosity calculations, the model results provide a means of exploring199

general mechanical consequences of porosity changes and cementation.200

201

3.3 Compression and Extension Tests202

Confined triaxial compression tests (σ 1 > σ 2 = σ 3) were performed by shortening the203

specimen along its long axis with top and bottom platens using a constant velocity204

that is slow enough to ensure quasi-static conditions, whilst maintaining a constant205

confining pressure between 0.1 and 40 MPa using servo-controlled lateral platens.206

The failure envelopes were constructed using the peak stress (σ 1) value of the stress207

strain curve at a given confining pressure (σ 3) and the angle of (internal) friction was208

calculated from the slope of the principal stress data (Eq.1).209

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 12/42

Confined triaxial extension tests (σ 1 = σ 2 > σ 3) were performed using210

particles to apply boundary forces and velocities. The sample was first confined to the211

desired confining pressure using servo-controlled platens. Then particles touching the212

platens are identified, the platens are removed, one calculation cycle is performed, and213

the out-of-balance forces of the boundary particles are replaced by applied forces with214

the same magnitude but opposite direction. Particles of the upper and lower 10% of215

the sample are then combined to form two non-breakable clumps which are then216

pulled apart while the lateral forces are kept constant. Since a velocity is applied to all217

particles within the upper and lower portions of the model, stress concentrations that218

would arise if the model would be extended using clamps are eliminated. The219

stableness of the boundary condition used is supported by the fact that macroscopic220

failure never occurred along the edge of the clumps, but within the central part of the221

model, most likely due to elastic necking. The axial stress (σ 3) is computed by222

dividing the average out-of-balance force of the clumps by the cross-sectional area of223

the sample. Preliminary results suggest that comparison of the tensile strength values224

obtained from the direct tension tests with those derived from Brazilian disc tests is225

not straightforward, since the Brazilian strength values are sensitive to both disc226

thickness and the width of the loaded section, and disc failure occurs at the edge of the227

models, rather than in the centre of the disc, as predicted for materials with low228

UCS/T values [35].229

Young’s modulus and Poisson’s ratio were obtained from uniaxial strain tests230

(e1 ≠ 0, e2 = e3 = 0) by fixing the lateral platens and shortening the sample vertically231

(e1 > 0) until the first bond breakage occurs. The elastic parameters were calculated232

using the final stresses acting on the platens by [1]233

234

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 13/42

11 )2( eG+= λ σ , 13221 )( eλ σ σ =+ , (2)235

236

where λ and G are Lame’s constants.237

238

4 Results and Discussion239

The models replicate a wide range of behaviours observed in laboratory deformation240

of rock, in terms of the stress-strain behaviour, the shapes of the failure envelopes and241

their dependence on the numbers of non-bonded contacts (cracks) and porosity. These242

aspects of the model results are discussed in sequence in the following sections.243

244

4.1 Stress-Strain Curves245

Stress difference and volumetric strain (volume decrease taken as negative) vs axial246

strain curves of the two end-member models (framed in Fig. 2) at various confining247

pressure are shown in Fig. 4. These curves show a variety of differences in248

mechanical behaviour between the high and low porosity models. The most obvious249

difference is that the slopes of the stress-strain curves and the peak stress values are250

much greater in the low porosity model. The slope of the stress-strain curve of a251

triaxial compression test is Young’s modulus (d σ 1/d e1 = E) and the slope of the252

volumetric strain curve is a function of Poisson’s ratio (d ev/d e1 = 2ν -1). The curves in253

Fig. 4 therefore show that, Young’s modulus is strongly dependent on porosity,254

moderately dependent on the percentage of bonded contacts and weakly dependent on255

confining pressure. The first two dependencies are discussed later; the pressure256

dependence of Young’s modulus is shown in Fig. 5a, together with the results257

obtained from uniaxial strain tests. Poisson’s ratio, however, is only weakly258

dependent on porosity and the percentage of bonded contacts, but very sensitive to259

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 14/42

confining pressure. Especially at low confinement, Poisson’s ratio is much greater260

than the values obtained from the uniaxial strain tests (Fig. 5b). This pressure261

sensitivity of Poisson’s ratio is even more pronounced in partially bonded materials,262

which exhibit volume increase from the onset of axial shortening (dotted curves in263

Fig. 4b and e), hence Poisson’s ratios of >0.5 are obtained. These high values264

obtained from triaxial compression tests at low confinement are, however, not265

representative and therefore uniaxial strain test results are given throughout the paper.266

The stress-strain curves of the high and low porosity models do share,267

however, a number of similarities, e.g. the stress-difference and strain at failure268

increases with increasing confinement (Fig. 4). Additionally, the stress-drop after269

failure decreases and becomes less abrupt with both, increasing confinement and270

increasing number of non-bonded contacts, i.e. the material becomes less brittle. It is271

important to note, however, that Young’s modulus, strength and stress-drop can be272

increased by increasing both the particle stiffness and the bond strength without273

significantly modifying the friction angle and UCS/T as long as a load-bearing274

framework exists within the model. In the non-bonded models hardly any stress-drop275

is observed and these materials deform at an approximately constant stress-difference276

(although not constant volume) after an initial non-linear stress increase (Fig. 4c and277

f).278

Stress-strain curves obtained from unconfined compression tests on the ten279

models shown in Fig. 2 are plotted in Fig. 6 (for fully bonded models). These curves280

illustrate that porosity has a strong impact on both peak stress and Young’s modulus.281

The particle size distribution (uniform/bimodal and power-law, Fig. 6a and b,282

respectively) has an impact on the elastic properties, where slightly higher Young’s283

moduli and (for low confinement) higher Poisson’s ratios are observed in the power-284

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 15/42

law material. A more quantitative description of these mechanical properties/porosity285

relations is given in Section 4.5.286

287

4.2 Shape of Failure Envelopes288

Failure envelopes were constructed using peak stress values (dots in Figs. 4 and 6)289

and are plotted in principal stress diagrams in Fig. 7. The failure envelopes for the290

non-bonded materials are straight, i.e. the cohesionless materials exhibit Coulomb-291

type behaviour. The envelopes obtained from triaxial compression tests on bonded292

model materials are concave towards the minimum principal stress axis (the data293

points at σ 3 = 0 are the UCSs). Therefore, the addition of cohesion (i.e. cement) does294

not simply shift the straight failure envelope of the non-bonded material towards295

higher strength (σ 1) values, but also introduces a non-linear pressure strength296

dependence. As a consequence the angles of internal friction of the various bonded297

materials decrease non-linearly with increasing confinement, to values which are298

lower than the interlocking/sliding friction of the non-bonded material (Fig. 7c). Our299

model results are therefore in agreement with theoretical considerations [7], which300

suggest that the phenomenon of internal friction and the non-linearity of failure301

envelopes for rock can be explained by the frictional resistance to sliding offered by302

the fractured volume that comprises part of the incipient fault plane.303

The failure envelopes in the tensile field (σ 3 < 0) are non-linear and are304

‘overturned’ at low confining pressures (Fig. 7a and b). This strengthening effect is305

neither predicted from critically stressed crack theory (Griffith criterion) nor is it306

observed in lab experiments on low-porosity, crystalline rock [9,10]. However, an307

increase in tensile strength at low confining pressures was observed in confined308

triaxial extension tests on Berea sandstone (φ = ~19%; Fig. 1a [29]), which was309

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 16/42

deformed using the same procedure as described in Ref. 9. The model failure310

envelopes shown in Fig. 7a and b illustrate that the strengthening effect becomes more311

pronounced with increasing porosity and increasing percentage of non-bonded312

contacts suggesting it is confinement related.313

The unconfined biaxial strength (σ 1 = σ 2 > 0, σ 3 = 0), which is the intercept314

of the triaxial extension failure envelope with the σ 1 axis, is greater than the UCS (σ 1 315

> 0, σ 2 = σ 3 = 0). This strength difference is due to a σ 2-dependence of strength;316

hence Mohr criteria cannot be used for fully describing failure envelopes of cohesive317

DEM materials, and more complicated criteria that take the effect of the intermediate318

stress on strength into account need to be considered, details of which are given in the319

next section.320

321

4.3 Failure Criterion322

The misfit between the triaxial extension and triaxial compression failure envelopes in323

Fig. 7a and b indicates that a Mohr criterion, where the maximum principal stress at324

failure is a function of the minimum principal stress only, can not be used to fit our325

model data. A variety of polyaxial criteria have been proposed in the past [3,8]: Here326

we use the Mogi 1967 empirical criterion [30] for quantifying the σ 2-dependence of327

strength, which is written as328

329

]2/)[(2/)( 32131 σ βσ σ σ σ ++=− f , (3)330

331

where β is a constant smaller than 1 that reflects the σ 2-dependence in332

strength, i.e. the criterion reduces to a Mohr criterion if β equals 0. f is some333

monotonically increasing function; linear, power-law and parabolic functions are the334

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 17/42

most commonly used. The best-fit to our data was obtained using a parabolic335

function. Our analysis revealed that the best-fit β -values are independent of the336

percentage of non-bonded contacts, but are different for the two end-member porosity337

models, and are 0.19 for the 37% and 0.13 for the 23% porosity models (Fig. 8).338

Interestingly a parabolic function with a β -value of 0.14 gives a good fit to the triaxial339

extension and triaxial compression test results of Berea sandstone (φ = ~19%; Fig.340

1b). Those results provide some indication that porosity has an important control on341

the β -value. Additionally no polyaxial data, where all principal stresses are different,342

were used for determining the best-fit failure criterion in this study and it is likely that343

polyaxial data will reveal that a different criterion to that used here needs to be344

considered for fully describing the 3D failure envelope of cohesive DEM materials.345

346

4.4 Impact of Non-Bonded Contacts, or Pre-Existing ‘Cracks’347

From the failure envelopes shown in Fig. 7 and 8 it is clear that the strength of the348

model material not only depends on porosity but also on the relative abundance of349

non-bonded contacts. These non-bonded contacts could be considered to be analogous350

to non-cemented grain contacts in rock or perhaps more generally to closed, pre-351

existing cracks, where sliding occurs if a critical shear stress given by Coulomb352

friction is exceeded. The percentage of non-bonded contacts, which is the measure353

used throughout this paper to describe the proportion of cement, is clearly related to354

crack density as used in micromechanical models [1], but a direct quantitative355

comparison is difficult and beyond the scope of this study. Although we follow earlier356

analytical and laboratory studies by describing model results in terms of crack357

density, a direct link with uncemented grain-grain contacts is more valid (for example,358

high proportions of uncemented grain contacts are features of poorly lithified359

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 18/42

sandstones). The model results indicate that the strength of model materials decreases360

with increasing number of non-bonded contacts (Fig. 9a). Our models also show that361

the presence of non-bonded contacts has a greater impact on tensile strength than on362

compressive strength, a feature which reflects the fact that a non-bonded contact can363

bear some load in compression but no load in tension. Consequently the ratio of364

unconfined compressive strength to tensile strength (UCS/T) increases with365

increasing percentage of non-bonded contacts (Fig. 9b). A similar impact of pre-366

existing cracks on strength and UCS/T for rock was demonstrated in Ref. 16, where367

an increase of UCS/T from ~20 for intact sandstone to about 50 for sandstone with368

partially disintegrated grain boundaries is reported (Fig. 1f and g). Most importantly,369

the UCS/T ratios obtained from only partially bonded model materials are within the370

range of those described for rock, which tend to have strength ratios of ~10 [1].371

Fig. 9b shows that UCS/T also depends on model porosity, with higher372

UCS/T values obtained for lower porosity materials. The similarity between the373

UCS/T ratios for the 37% porosity PFC3D material used in this study and the 35%374

porosity model of Lac du Bonnet granite (see caption) with very different375

microproperties and sample shape is consistent with porosity exerting a significant376

control on UCS/T. The ESyS data show that UCS/T is, for the range of model sizes377

tested in this study, basically independent of model resolution. Low porosity (22-378

23%) PFC3D and ESyS data, apart from the fully bonded PFC3D model, exhibit379

identical ratios and trends, which suggests that the details of the contact and bond380

implementations have only marginal affects on UCS/T ratios of models with more381

than ca 10% non-bonded contacts. Significant differences of UCS/T for the fully382

bonded low-porosity models are only weakly dependent on porosity (Fig. 10b) and383

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 19/42

therefore must reflect sensitivities in mechanical behaviour due to contact/bond384

implementations.385

The presence of non-bonded contacts also has an impact on the elastic386

properties (Fig. 9c): Young’s modulus ( E ) decreases whereas Poisson’s ratio (ν )387

increases with increasing percentage of non-bonded contacts. These general trends are388

also predicted by various micromechanical models for linear elastic materials389

containing randomly oriented, closed cracks (e.g. chapter 10 in Ref. 1) and similar390

relations were observed in cyclic loading experiments on granite [31], and391

experiments on sandstone with partially disintegrated grain boundaries (Fig. 1h; [16]).392

393

4.5 Porosity Relations394

Both tensile strength (T) and unconfined compressive strength (UCS) decrease with395

increasing porosity and are basically independent of the PSD (Fig. 10a). This decrease396

in strength with increasing porosity is consistent with empirical rock property397

relations (Fig. 1c; [4]). In the models UCS, however, decreases more rapidly than T,398

and consequently UCS/T decreases with increasing porosity (Fig. 10b). The UCS/T399

ratios of the ESyS models exhibit a similar relation, though the ratios are, for a given400

porosity, greater than those obtained from PFC3D models, and also decrease more401

rapidly with increasing porosity (Fig. 10b). We believe that these results reflect the402

differences of the bond model implementations in PFC3D and ESyS.403

The friction angles for non-bonded materials with various PSDs and404

porosities are shown in Fig. 10c together with the range of internal friction angles405

determined for the fully bonded end-member models (Fig. 7c). The friction angles for406

the non-bonded materials decrease (almost) linearly with increasing porosity and are407

(almost) independent of the PSD (Fig. 10c). The internal friction angles suggest a408

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 20/42

similar relation, though the scatter is significant due to non-linearity of the failure409

envelopes, especially at low confining pressures. Nevertheless, this general trend has410

also been described for natural rock (Fig. 1d; [4,14]). We believe that the decrease in411

friction angles with increasing porosity is due to a decrease of internal roughness,412

though future micromechanical studies are necessary to fully understand the relation413

of the angle of (internal) friction with porosity.414

Young’s modulus decreases significantly with increasing porosity, though415

the modulus is greater for the power-law than for the uniform and bimodal PSD416

models (Fig. 10d). Poisson’s ratio is (almost) independent of porosity, but higher for417

the uniform/bimodal than the power-law PSD models. The decrease in Young’s418

modulus with increasing porosity and the porosity-independence of Poisson’s ratio are419

consistent with micromechanical models [1], with data obtained from continuum420

method models [32], and with empirical rock property relations (Fig. 1e; [4]).421

Finally, as stated earlier, some of the Young’s modulus and strength values422

of the model materials are greater than those for real rock. However, since E and UCS423

(and T) are proportional to particle and bond stiffnesses, and to bond strengths,424

respectively, calibration of the model material to that of real rock (e.g. sandstone)425

should be straightforward and will be the aim of future studies.426

427

5 Summary and Conclusions428

The mechanical properties of rock and other materials are strongly dependent on429

porosity and crack density. In this study we investigate some of these dependencies430

using the Discrete Element Method (DEM) in 3D and a selection of results is shown431

in Fig. 11. Young’s modulus, strength, UCS/T and angle of (internal) friction decrease432

with increasing porosity. The elastic constants, however, also depend on confining433

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 21/42

pressure, where Young’s modulus and Poisson’s ratio increase and decrease with434

increasing pressure, respectively. The failure envelopes of the cohesive materials are435

non-linear and the observed misfit between triaxial extension and compression436

envelopes is due to a σ 2-dependence in strength, which is more pronounced in the437

high porosity materials. Young’s modulus, strength and UCS/T decrease whereas438

Poisson’s ratio increases with decreasing cement content (increasing ‘crack’ density).439

While we have not attempted to match the range of properties of any440

particular rock, our numerical test results replicate both qualitatively and441

quantitatively the range of mechanical behaviours observed for brittle rock. Perhaps442

most importantly, by varying porosity and the proportion of bonded contacts in DEM443

materials comprised of spherical particles, it is possible to achieve the high UCS/T444

ratios and the range of angles of internal friction that are observed in rocks. These445

high UCS/T ratios and friction angles were previously only reproducible by446

modifying the DEM (using irregular shaped particles, or implementing rolling447

resistance).448

Many low-porosity, crystalline rocks exhibit UCS/T ratios greater than 10,449

i.e. greater than those achieved using the particle and bond properties of the present450

study. Although UCS/T > 10 can be easily achieved by using a greater proportion of451

non-bonded contacts (Fig. 9b), the stress and especially the volumetric strain452

behaviour becomes less similar to that observed in brittle rock (though, as expected,453

the behaviour does match that of poorly lithified, granular materials). In low-porosity454

crystalline rocks that exhibit UCS/T >10, grain interlocking and the resistance to grain455

rolling are important mechanisms that increase both friction and UCS/T. Hence it456

might be necessary to use irregular shaped particles or a particle rolling resistance457

method for modelling such low-porosity rocks. These methods have, however,458

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 22/42

associated disadvantages, for example the lateral strains are not matched if459

unbreakable clumps are used [5, 22]. The decision as to whether to use these460

approaches or the methods outlined in this article depends on which aspects of the461

rock mechanical behaviour need to be captured in the model.462

Our study highlights the fact that both porosity and the proportion of bonded463

contacts (crack density) are important parameters that should be considered during the464

calibration of DEM materials to rocks. Including these two parameters provides a465

means of modelling a wider range of rock types than was previously possible [33].466

The relationships we observed between these two parameters and a range of467

mechanical properties closely replicate the equivalent relationships determined468

experimentally for rocks.469

470

Acknowledgments471

Childs, Schöpfer and Walsh acknowledge funding from a Science Foundation Ireland472

(SFI) grant, an Irish Research Council for Science, Engineering and Technology473

(IRCSET) Embark initiative postdoctoral research grant and financial support from474

ExxonMobil and Shell. Abe acknowledges funding from the EU-SPICE project.475

Abe’s ESyS simulations were performed on the computing cluster of the Seismology476

& Computational Rock Physics Laboratory at University College Dublin. Stimulating477

discussions with P. Cundall, M. Pierce and D. Potyondy (HCItasca) and T. Manzocchi478

(Fault Analysis Group) are gratefully acknowledged. Constructive comments of two479

anonymous reviewers and the editorial advice of R. Zimmerman are acknowledged.480

481

References 482

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 23/42

[1] Jaeger JC, Cook NGW, Zimmerman RW. Fundamentals of rock mechanics. 4th 483

edition, Blackwell Publishing, Oxford, 2007.484

[2] Paterson, MS, Wong T-F. Experimental rock deformation – the brittle field.485

Springer, Berlin-Heidelberg, 2005.486

[3] Mogi K. Experimental rock mechanics. Geomechanics Research Series 3. Taylor487

& Francis Group, London, 2007.488

[4] Chang C, Zoback MD, Khaksar A. Empirical relations between rock strength and489

physical properties in sedimentary rocks. J Petr Sci Eng 2006;51:223-37.490

[5] Potyondy DO, Cundall PA. A bonded-particle model for rock. Int J Rock Mech491

Min Sci 2004;41:1329-64.492

[6] Cundall PA. A discontinuous future for numerical modelling in geomechanics?493

Geotech Eng 2001;149:41-47.494

[7] Savage, JC, Byerlee JD, Lockner DA. Is internal friction friction? Geophy. Res495

Let 1996;23:487-90.496

[8] Colmenares LB, Zoback MD. A statistical evaluation of intact rock failure criteria497

constrained by polyaxial test data for five different rocks. Int J Rock Mech Min Sci498

2002;39:695-729.499

[9] Ramsey JM, Chester FM. Hybrid fracture and the transition from extension500

fracture to shear fracture. Nature 2004;428:63-66.501

[10] Engelder T. Transitional-tensile fracture propagation: a status report. J Struct502

Geol 1999;21:1049-55.503

[11] Vernik L, Bruno M, Bovberg C. Empirical relations between compressive504

strength and porosity of siliciclastic rocks. Int J Rock Mech Min Sci 1993;30:677-505

80.506

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 24/42

[12] Bell FG, Lindsay P. The petrographic and geomechanical properties of some507

sandstones from the Newspaper Member of the Natal Group near Durban, South508

Africa. Eng Geol 1999;53:57-81.509

[13] Palchik V. Influence of porosity and elastic modulus on uniaxial compressive510

strength in soft brittle porous sandstones. Rock Mech Rock Engng 1999;32:303-09.511

[14] Palchik V. Application of Mohr–Coulomb failure theory to very porous sandy512

shales. Int J Rock Mech Min Sci 2006;43:1153-62.513

[15] Rosengren KJ, Jaeger JC. The mechanical properties of an interlocked low-514

porosity aggregate. Géotechnique 1968;18:317-26.515

[16] Mahmutoglu Y. Mechanical behaviour of cyclically heated fine grained rock.516

Rock Mech Rock Eng 1998;31:169-79.517

[17] PFC3D (Particle Flow Code in Three Dimensions). Version 3.1. Minneapolis:518

Itasca Consulting Group, 2005.519

[18] Abe S, Place D Mora P. A parallel implementation of the lattice solid model for520

the simulation of rock mechanics and earthquake dynamics. PAGEOPH521

2004;161:2265-77.522

[19] Wang Y, Abe S, Latham S, Mora P. Implementation of particle-scale rotation in523

the 3-D Lattice Solid Model. PAGEOPH 2006;163:1769-85.524

[20] Thornton C. Numerical simulations of deviatoric shear deformation of granular525

media. Géotechnique 2000;50:43-53.526

[21] Boutt DF, McPherson BJOL. Simulation of sedimentary rock deformation: Lab-527

scale model calibration and parameterization. Geophys Res Lett 2002;29:1054.528

[22] Cho N, Martin CD, Sego DC. A clumped particle model for rock. Int J Rock529

Mech Min Sci 2007;44:997-1010.530

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 25/42

[23] Ting JM, Khwaja M, Meachum LR, Rowell JD. An ellipse-based discrete531

element model for granular materials. Int J Numer Anal Methods Geomech532

1993;17:603–23.533

[24] Iwashita K, Oda M. Rolling resistance at contacts in simulation of shear band534

development by DEM. J Engrg Mech 1998;124:285-92.535

[25] Egholm DL. A new strategy for discrete element numerical models: 1. Theory. J536

Geophys Res 2007;112:B05203.537

[26] Fakhimi A. Application of slightly overlapped circular particles assembly in538

numerical simulation of rocks with high friction angles. Eng Geol 2004;74:129-38.539

[27] Bagi K. An algorithm to generate random dense arrangements for discrete540

element simulations of granular assemblies. Granular Matter 2005;7:31-43.541

[28] Place D, Mora P. A random lattice solid model for simulation of fault zone542

dynamics and fracture process. In: Bifurcation and Localisation Theory in543

Geomechanics, Balkema Rotterdam/Brookfield, 2001.544

[29] Bobich JK. Experimental analysis of the extension to shear fracture transition in545

Berea Sandstone. MSc thesis, Dept of Geol & Geophys, University of Texas at546

Austin, 2005.547

[30] Mogi K. Effect of intermediate principal stress on rock failure. J Geophys Res548

1967;72:5117-31.549

[31] Faulkner DR, Mitchell TM, Healy D, Heap MJ. Slip on 'weak' faults by the550

rotation of regional stress in the fracture damage zone. Nature 2006;444:922-25.551

[32] Avar BB, Hudymab N, Karakouziana M. Porosity dependence of the elastic552

modulus of lithophysae-rich tuff: numerical and experimental investigations. Int J553

Rock Mech Min Sci 2003;40:919-28.554

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 26/42

[33] Yoon J. Application of experimental design and optimization to PFC model555

calibration in uniaxial compression simulation. Int J Rock Mech Min Sci556

2007;44:871-889.557

[34] Wong T-F, David C, Zhu W. The transition from brittle faulting to cataclastic558

flow in porous sandstones: Mechanical deformation. J Geophys Res559

1997;102:3009-25.560

[35] Fairhurst C. On the validity of the ‘Brazilian’ test for brittle materials. Int J Rock561

Mech Min Sci 1964;1:535-546.562

563

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 27/42

Figure captions564

565

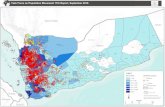

Fig. 1. Failure envelopes and rock property relations of siliciclastic rocks. (a) Peak566

stress data obtained from triaxial extension tests on Berea sandstone at various567

confining pressures plotted in principal stress diagram. (b) Data shown in (a) together568

with results from triaxial compression tests on Berea sandstone plotted on a maximum569

shear stress vs mean stress diagram. Best-fit parabolic Mogi 1967 failure criterion570

[30] is shown (Texas A&M data from Ref. 29, Wong et al. data from Ref. 34). (c)571

Strength at various confining pressure (labelled curves), (d) friction angle and (e)572

Young’s modulus vs porosity for Donetsk sandstone (data in (c) and (d) from Ref. 14,573

and data in (e) from Ref. 13). (f) Unconfined compressive and tensile strength (UCS574

and T, respectively), (g) UCS/T and (h) Young’s modulus vs number of heating575

cycles for Buchberger sandstone (data from Ref. 16).576

577

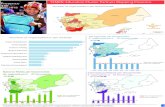

Fig. 2. PFC3D models used in this study. The two end-member models (i and ii) are578

comprised of ~27,000 particles and their particle size distributions are shown in Fig.579

3.580

581

Fig. 3. Plot of cumulative number of particles vs particle radius normalised to the582

sample width for the two end-member models (framed in Fig. 2).583

584

Fig. 4. Stress difference and volumetric strain vs axial strain curves obtained from585

triaxial compression tests at different confining pressures. Plots in left column are for586

high porosity end-member (model i in Fig. 2) and the plots in the right column are for587

low porosity end-member (model ii in Fig. 2). Model results in the first row were588

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 28/42

obtained from fully bonded models, results in second row from models with half of589

the particle-particle contacts bonded, and results in third row from non-bonded590

models. The open dots are the peak stress values which were used for constructing the591

failure envelopes shown in Fig. 7.592

593

Fig. 5. (a) Young’s modulus and (b) Poisson’s ratio vs confining pressure obtained594

from the slopes of the stress-strain curves shown in Fig. 4a and d (fully bonded595

models). Open and filled symbols are data from low and high porosity models,596

respectively. Elastic properties were determined at an axial strain of a tenth of the597

strain at peak stress. Circles and squares denote tangent and secant moduli,598

respectively. The dashed horizontal lines in each graph are the elastic property values599

obtained from the uniaxial strain tests.600

601

Fig. 6. Stress difference and volumetric strain vs axial strain curves obtained from602

unconfined compression tests on the models shown in the (a) first and (b) second row603

of Fig. 2. Open dots are peak stress values, which are plotted vs porosity in Fig. 10a.604

605

Fig. 7. (a and b) Failure envelopes of the two end-member models (framed in Fig. 2)606

in principal stress diagrams, and (c) friction angle (obtained from the slopes of triaxial607

compression failure envelopes) vs average confining pressure. Labels ranging from 10608

to 50 are percentages of non-bonded contacts. For clarity envelopes obtained from609

triaxial extension tests are cut off at the σ 1 axis. The misfit between the triaxial610

extension and triaxial compression envelopes is due to a σ 2 dependence of strength.611

612

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 29/42

Fig. 8. Data shown in Fig. 7 plotted in maximum shear stress vs mean stress diagrams613

(same line styles as in Fig. 7) for (a) a power-law PSD material with 23% porosity614

and (b) a uniform PSD material with 37% porosity. Labels ranging from 10 to 50 are615

percentages of non-bonded contacts. The curves are best-fit parabolic functions that616

were obtained using a least-square regression and by systematically varying the β -617

value given in Eq. (3).618

619

Fig. 9. (a) Unconfined compressive and tensile strength (UCS and T, respectively),620

(b) UCS/T, and (c) elastic properties vs percentage of non-bonded contacts. Keys to621

the curves are shown: the numbers followed by a k (= thousand) is the approximate622

number of particles comprising the models, and φ is the porosity. LdB are UCS/T data623

from PFC3D models of cylindrical specimens of Lac du Bonnet granite provided by624

David Potyondy (microproperties given in Ref. 5).625

626

Fig. 10. Plots of (a) unconfined compressive and tensile strength (UCS and T,627

respectively), (b) UCS/T, (c) friction angle, and (d) elastic properties vs porosity. Data628

in (a, b and d) were obtained from fully bonded materials and data in (c) from non-629

bonded materials (using the same range of confining pressure as in Fig. 7c). The bars630

in (c) indicate the range of internal friction angles obtained for fully bonded materials631

(Fig. 7c); arrows point towards increasing confinement. ESyS models (UCS/T data in632

b) with various porosities were generated by varying the particle size range for the633

particle insertion method (see text for details).634

635

Fig. 11. Chart summarizing some of the mechanical property relations obtained in this636

study. σ = stress/strength, ε = strain, P = confining pressure, E = Young’s modulus, ν 637

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 30/42

= Poisson’s ratio, ϕ = friction angle, and ρ crks = ‘crack density’ or percentage of non-638

bonded contacts. Solid curves are for fully or partially bonded materials, dashed639

curves for non-bonded materials. The graphs are selected results from Figs. 4, 5, 7 and640

9. See text for further explanation.641

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 31/42

Table 1642

PFC3D microproperties643

Symbol Descriptiona Value

E c, GPa Young’s modulus of particles 50

k n / k s ratio of particle normal to shear stiffness 2.5

µ c particle contact friction coefficient 0.5

c E , GPa

cement (i.e. bond) modulus 50

nk /

sk

ratio of bond normal to shear stiffness 2.5

cσ , MPa average tensile bond strength (standard deviation) 100 (20)

cτ , MPa average shear bond strength (standard deviation) 100 (20)

λ bond width multiplier 1

a Definition of microproperties and modulus-stiffness scaling relations are given in644

Ref 5.645

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 32/42

15 0

0

0

2

2

2

4

4

4

6

6

6

8

8

8

10

10

10

12

12

12

14

14

14

16

16

16

18

18

18

20 25 30 35 40 45 50 550 0

10

21.0

0 0

50

0 50 100 150 200 250 300 350 400

100

150

200

20

40

60

80

100

120

140

160

180

1.5

2.0

2.5

3.0

4

6

8

10

12

20

30

40

50

60

20

40

60

80

100

10

20

30

40

50

60

70

80

porosity [%]

porosity [%]

porosity [%] number of heating cycles

number of heating cycles

number of heating cycles

s t r e n g t h [ M P a ]

s t r e n g t h [ M P a ]

Y o u n g ' s m o d u l u s [ G P a

]

Y o u n g ' s m o d u l u s [ G P a

]

[ M P a ]

1

=

-

[ M P a ]

m a x

1

) / 2 3

[MPa]3 = (+ 0.14+m 1 2 )/2 [MPa]3

f r i c t i o n a n g l e , [ º ]

U C S / T

15

15

-10 -5 0 5 10 15

20

20

25

25

30

30

35

35

40

40

45

45

50

50

55

55

35

40

45

50

55

60

65

UCS

T

= -0.001+ 0.811+ 7.018max m m

2

2

3

0

1

23

confining pressure [MPa]

a b

f c

gd

he

triaxial extensiontriaxial compressiontriaxial compression

Texas A&M

Wong et al.

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 33/42

porosity increase

u n i f o r m /

b i m o d a l P S D

p o w e r - l a w

P S D

particle insertion

particle deletion

(i)

(ii)

23.0% 26.5% 30.0% 33.5% 37.0%

Figure 2

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 34/42

1

10

100

1000

10000

100000

0.10.01

c u m u l a t i v e n u m b e r

particle radius / sample width

uniform PSD

power-law PSD

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 35/42

0

0

0

0

0

0

0.0

0.0

0.0

0.0

0.0

0.0

-0.1

-0.1

-0.1

-0.1

-0.1

-0.1

-0.2

-0.2

-0.2

-0.2

-0.2

-0.2

-0.3

-0.3

-0.3

-0.3

-0.3

-0.3

0.1

0.1

0.1

0.1

0.1

0.1

0.2

0.2

0.2

0.2

0.2

0.2

100

100

100

100

100

100

200

200

200

200

200

200

300

300

300

300

300

300

400

400

400

400

400

400

500

500

500

500

500

500

0.0

0.0

0.0

0.0

0.0

0.0

0.1

0.1

0.1

0.1

0.1

0.1

0.2

0.2

0.2

0.2

0.2

0.2

0.3

0.3

0.3

0.3

0.3

0.3

0.4

0.4

0.4

0.4

0.4

0.4

0.5

0.5

0.5

0.5

0.5

0.5

s t r e s s d i f f e r e n c e , -

[ M P a ]

1

3

s t r e s s d i f f e r e n c e ,

-

[ M P a ]

1

3

s t r e s s d i f f e r e n c e ,

-

[ M P a ]

1

3

s t r e s s d i f f e r e n c e , -

[ M P a ]

1

3

s t r e s s d i f f e r e n c e ,

-

[ M P a ]

1

3

s t r e s s d i f f e r e n c e ,

-

[ M P a ]

1

3

v o l u m e t r i c s t r a i n [ % ]

v o l u m e t r i c s t r a i n [ % ]

v o l u m e t r i c s t r a i n [ % ]

v o l u m e t r i c s t r a i n [ % ]

v o l u m e t r i c s t r a i n [ % ]

v o l u m e t r i c s t r a i n [ % ]

axial strain [%]

axial strain [%]

axial strain [%]

axial strain [%]

axial strain [%]

axial strain [%]

f u l l y b o n d e d

5 0 %

b o n d e d c o n t a c t s

n o n - b o n d e d

5

1

15

2

25

3

35

4

1

5

1015

20

2530

35

40

0.1

confining pressure

peak stress

a d

b e

c f

Uniform particle size distribution

Porosity= 37%

Power-law particle size distribution

Porosity= 23%

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 36/42

0

0

0

0.00

0.25

0.50

20

40

60

80

100

120

140

160

180

5

5

10

10

15

15

20

20

25

25

30

30

35

35

40

40

Y o u n g ' s m o d u l u s [ G P a ]

P o i s s o n ' s r a t i o

confining pressure [MPa]

= 23%

= 23%

= 37%

= 37%

a

b

uni ax i al s t r ai n t e s t r e s ul t s

tangent

secant

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 37/42

0.00 0.00

0.05 0.05

-0.05 -0.05

0.10 0.10

-0.10 -0.100.0 0.00.1 0.10.2 0.20.3 0.30.4 0.40.5 0.5

0 0

50 50

100 100

150 150

200 200

250 250

300 300

350 350

s t r e s s d i f f e r e n c e ,

-

[ M P a ]

1

3

v o l u m e t r i c s t r a i n [ % ]

axial strain [%] axial strain [%]

2

3

0

2

6

5

3

0

0

3

3

5

3

7

0

Porosity

a bUniform/Bimodal PSD Power-law PSD

2 3 . 0 %

2 6 . 5 %

3 0. 0 %

3 3. 5 %

3 7. 0 %

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 38/42

-80 -80-40 -40-60 -60-20 -200 020 2040 40

500 500

400 400

300 300

200 200

100 100

0 0

minimum principal stress,[MPa]3 minimum principal stress,[MPa]3

m a x i m u m p

r i n c i p a l s t r e s s ,

[ M P a ]

1

m a x i m u m p

r i n c i p a l s t r e s s ,

[ M P a ]

1

ba

c

triaxial extension

triaxial compression

triaxial extension

triaxial compression

fully bonded

fully bonded

fully bonded

fully bonded

non-bonded

non-bonded

non-bonded

non-bonded

010

20

30

40

50

10 20 30 40

a n g l e

o f ( i n t e r n a l ) f r i c t i o n ,

[ ° ]

average confining pressure [MPa]

Uniform particle size distribution

Porosity= 37%

Power-law particle size distribution

Porosity= 23%

2

4

1 0

2 0

3 0

4 0

5 0

2

4

5

1 0

2 0

3 0

4 0

5 0

= 23%

= 37%

10

2 0

3 0

4 0

5 0

1 0

2030

405 0

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 39/42

-25 0

0-50 50 100 150 200 250 300

0

0

50

100

150

200

250

25

50

75

100

125

25 50 75 100 125 150

m a x . s h e a r s t r e s s ,

= (

-

) / 2 [ M P a ]

m a x

1

3

m a x . s h e a r s t r e s s ,

= ( -

) / 2 [ M P a ]

m a x

1

3

mean stress,= (+ 0.13+)/2 [MPa]m 1 2 3

mean stress,= (+ 0.19+)/2 [MPa]m 1 2 3

a

b Uniform particle size distribution

Porosity= 37%

Power-law particle size distribution

Porosity= 23%

= a+ bmax m + cm

2

= a+ bmax m + cm

2

triaxial extensiontriaxial compression

triaxial extensiontriaxial compression

fully bonded

fully bonded

non-bonded

non-bonded

1 0

1 0

2 0

2 0

3 0

3 0

4 0

4 0

5 0

5 0

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 40/42

0

0

0

10

10

10

20

20

20

30

30

30

40

40

40

50

50

50

2.5

5.0

7.5

10.0

12.5

percentage of non-bonded contacts

U C S / T

10 k

20 k

50 k

ESyS (= 22%)

= 23%PFC3D

= 37%

PFC3D (= 23%) 27 k (Model ii)

PFC3D (= 37%) 27 k (Model i)

PFC3D (= 35%) 8.4 k (LdB)

Y o u n g ' s m o d u l u s ,

E [ G P a ]

s t r e n g t h [ M P a ]

P oi s s on' s r a t i o ,

20

0

50

100

150

200

250

300

350

40

60

80

100

120

140

160

0.15

0.20

0.25

E

E

a

b

c

= 23%

PFC3D = 37%

U SUCS

U SUCS

TTTT

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 41/42

0.15

0.20

0.25

40

0

50

100

150

200

250

300

350

60

80

100

120

140

160

20

20

25

25

30

30

35

35

40

40

Y o u n g ' s m o d u l u s ,

E [ G P a ]

P oi s s on' s r a t i o ,

E

porosity,[%]

porosity,[%]

porosity,[%]

porosity,[%]

s t r e n g t h [ M P a ]

UCS

T

a

c

b

d

3

4

5

6

7

8

20

20

25

25

30

30

35

35

40

40

U C S / T

f r i c t i o n a n g l e , [ º ]

ESyS

50

45

40

35

30

25

20

15

power-law PSD

uniform/bimodal PSDPFC3D

i n t er n al f r i c t i on

8/11/2019 Schopfer Et Al IRMMS 2009 Repository

http://slidepdf.com/reader/full/schopfer-et-al-irmms-2009-repository 42/42

-

1

3

1 1

3 3

-

1

3

v o l

v o l

high porosity

-T

UCS

P

P

P

P

crks

crks

crks

crks

E

E

E

E

UCSUCS

TT

E

E

E

E

low porosity

s t r e s s v s a x i a l s t r a i n a n d

v o l u m e t r i c s t r a i n v s s t r a i n

e l a s t i c p r o

p e r t i e s v s

c o n f i n i n g

p r e s s u r e

f a i l u r e e n v e l o p e s i n

p r i n c i p a l s t r e s s d i a g r a m

f r i c t i o n a n g l e v s

c o n f i n i n g p r e s s u r e

u n c o n f i n e d s t r e n g t h v s

' c r a

c k ' d e n s i t y

e l a s t i c p r o p e r t i e s v s

' c r a c k ' d e n s i t y